Aerospace and defense systems integrators continue their reliance on radiation-hardened electronics

TECHNOLOGY FOCUS, 5 June 2012. Systems architects and integrators rely on radiation-hardened and radiation-tolerant innovations to ensure the extended, uninterrupted operation of electronics in space.

“Space is an extremely hazardous vacuum filled with lethal radiation, storms of micrometeoroids, extreme variations of temperature, and all manner of man-made debris. Any one or a combination of these can damage or even destroy unshielded satellites and other spacecraft,” explains a representative at the National Aeronautics and Space Administration (NASA) in Washington.

Space is wrought with radiation, which can alter the effectiveness of, interfere with, and even render useless myriad space-based systems. As a result, systems architects and systems integrators are turning to aerospace technology firms for the latest radiation-hardened and radiation-tolerant electronics components and solutions.

Essential for effectiveness

“High-reliability, radiation-hardened and radiation-tolerant components are vital in aerospace and defense applications,” insists Minh Nguyen, marketing manager, Space FPGAs (field-programmable gate arrays) at Microsemi Corp. in San Jose, Calif. After all, he continues, “they contribute to the reliability of the whole system and the success of the mission.

Aerospace, defense, and commercial applications and organizations rely heavily on space-based systems, such as communications satellites, driving the need for rugged and reliable electronics. “Failure is not an option in space, due to its great impact to civilian and national security if there is an interruption in service,” Nguyen adds.

Cost and convenience are also critical factors to consider, given the difficulties associated with servicing or replacing space-based electronics. “An aerospace or defense mission is usually costly and requires the highest-quality electronics because these are systems which have to work in an environment where there is no easy way to access, debug, and repair,” Nguyen affirms.

For these and other reasons, radiation-hardened and -tolerant components are “tested and screened to survive the most rigorous radiation in the space environment and maintain their reliability throughout the life of a mission,” Nguyen says.

Space standards

Aerospace professionals are seeing more stringent demands from engineers and managers for electronics components and systems that meet the highest quality standards, such as Qualified Manufacturer List (QML) Class V—considered to be the highest qualification for space integrated circuits (ICs).

U.S. Defense Logistics Agency officials have qualified Microsemi’s RTAX-S/SL radiation-tolerant field programmable gate arrays (FPGAs) under Qualified Manufacturers List (QML) Class V in accordance with military performance standard MIL-PRF-38535 space-level qualification requirements. QML Class V qualification provides designers and users of space-flight systems with an added level of assurance as to the quality and reliability of the RTAX-S/SL FPGA product family, says a representative.

The achievement marks an important milestone in the company’s history, according to Esam Elashmawi, vice president and general manager at Microsemi. "Microsemi has been providing high-reliability solutions to the aerospace market for more than five decades, and we delivered our first radiation-tolerant RTAX-S FPGA in 2004," he says.

Microsemi’s radiation-tolerant FPGAs have performed flight-critical functions in space systems orbiting around the Earth, Moon, Mars, Venus, and the Sun, as well as on missions to the surface of Mars and into the furthest reaches of the solar system, according to Nguyen.

“In many of these programs, like the Mars Science Lab and Lunar Reconnaissance Orbiter, Microsemi radiation-tolerant FPGAs play a vital role in control and telemetry applications for the spacecraft, as well as mission-critical science instruments,” Nguyen says. Microsemi radiation-tolerant FPGAs are currently employed in a variety of commercial and defense space programs and applications, including telemetry tracking and control, electrical power systems, digital communication payloads, radio-frequency communications payloads, imaging payloads, and solid-state recorders.

Astronomical HPC

The proven ability to mitigate the effects of radiation is just one of the requirements aerospace engineers must consider when selecting the optimal electronics for space-based systems. Military and commercial space customers are under the same pressures: higher functionality and higher performance, while not consuming excessive power, Nguyen notes. In fact, space customers in some programs—such as low Earth orbit, tactical, and short-duration programs—require a combination of reprogrammability, functionality, and radiation tolerance for the mission.

Modern space missions are collecting a wealth of data, driving the need for increased processing power and capacity. Engineers at BAE Systems in Manassas, Va., are developing fourth-generation, radiation-hardened computers for space applications using Power Architecture technology licensed from Freescale Semiconductor in Austin, Texas. Use of Freescale’s Power Architecture processor cores is expected to increase onboard satellite processing by 10 times the current rate, enabling high-performance computing (HPC) onboard satellites and parallel multi-core processing for myriad space applications.

“The licensing arrangement enables a massive leap in our processing capability, providing our customers the ability to maximize application performance while leveraging existing infrastructure and experience,” explains Ian McDonald, director of space products and systems at BAE Systems. “Freescale’s experience with high-performance computing provides BAE Systems a technological advantage to enable mission applications that are unattainable with current generation hardware platforms.”

BAE Systems’ space-qualified computer products and application specific integrated circuits (ASICs), more than 600 of which have been placed in orbit, can now benefit from Freescale’s e5500 64-bit Power Architecture core and QorIQ platform, including CoreNet and OCeaN fabrics, memory controller, memory elements, and high-speed interfaces.

Electronics assurances

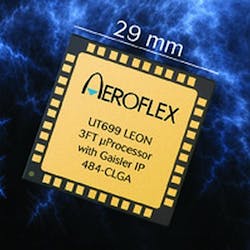

“The importance of radiation-hardened/tolerant electronics cannot be overstated; the assurance of highly reliable, qualified, and environmentally hardened devices are all key to the success of any aerospace application/program,” acknowledges Elaine Gonsalves, business development manager, Standard Products at Aeroflex in Colorado Springs, Colo. A variety of components—including microprocessors, memory, medium-scale integration (MSI) logic, ASICs, and power electronics—from Aeroflex are employed in such aerospace applications as command and data handling, FPGA boot loading, and SpaceWire routing.

The Core On-Board Computer (OBC) of a Germany University project, called the “Flying Laptop” micro satellite, uses several Aeroflex Colorado Springs Standard Products, Gonsalves reveals. “The project’s primary objectives are technology evaluation and earth observation,” she says.

The OBC uses the Aeroflex UT699 LEON 3FT SPARC V8 microprocessor, as well as the company’s static random-access memory (SRAM), RadClock and clock buffer, and several MSI logic devices. The project also employs software tools supporting the real-time executive for multiprocessor systems (RTEMS) operating system managed by OAR Corp. in Huntsville, Ala., and CCSDS IP from Aeroflex Gailser in Sweden. A flight variant of the OBC is currently undergoing integration testing, whereas the satellite is expected to launch in 2013.

SWaP in space

Designers and integrators of space-based systems are plagued by strict size, weight, and power (SWaP) requirements; yet, aerospace technology firms are partnering and innovating to help alleviate such challenges.

International Rectifier (IR), a provider of power-management technology in El Segundo, Calif., introduced its GH Series of RAD-Hard DC-DC converters to maximize efficiency for onboard spacecraft applications requiring long mission life, such as up to 15 years. GH Series devices are well suited for designs using digital signal processors and FPGAs that require a supply voltage as low as 1.0 volt, sport an internal electromagnetic interference (EMI) filter, and feature magnetically coupled feedback for robust operation in radiation environments.

“As a low output voltage, highly efficient solution, the GH Series addresses the ongoing need to reduce the overall size and weight of the system together with the increasing requirements of FPGA and other digital circuitries for increased bandwidth and data processing speed of spacecraft electronics,” says Tiva Bussarakons, marketing director for IR’s HiRel DC-DC converter products.

Powerful prospects

“A reliable, ongoing power supply is essential to a space mission’s success,” a European Space Agency (ESA) representative says. Power electronics, such as power conditioning and power conversion devices, can also help prevent harmful current surges and switch voltages.

International Rectifier power supplies are being used in low Earth orbit (LEO) and geosynchronous (GEO) satellite applications. “Radiation-hardened parts are required in most GEO satellites,” explains Michael Sullivan, director of marketing at International Rectifier. “In LEO satellites, the radiation often can move into radiation tolerance levels due to the location of the orbit and the duration of flight.

“In spacecraft, both radiation-hardened and radiation-tolerant are used,” Sullivan adds. “IR continues to develop new radiation-hardened devices for the space market as the number of satellites continues to grow both in size and in number.”

Aeroflex RAD in Colorado Springs, Colo., uses an “Intellectual Property Liberation” (IP Lib) model for delivering radiation-tolerant electronics for satellites systems, describes Joseph Benedetto, vice president, Radiation Technology at Aeroflex RAD. Aeroflex RAD partnered with Linear Technology Corp., also in Colorado Springs, to manufacture the RAD1419, a radiation-tolerant analog-to-digital (A/D) converter that uses the Linear Technology LTC1419, an A/D converter that draws 150mW from ±5-volt supplies.

“By partnering with Linear Technology and using the IP Lib model, Aeroflex RAD was able to introduce this product to the satellite community in a fraction of the time and at a fraction of the cost of traditional radiation-hardened components,” Benedetto says.

COTS considerations

Aerospace and defense organizations continue to invest in, and benefit from, commercial off-the-shelf (COTS) technologies and products.

“To reduce weight and component cost, distributed power systems are relying more on smaller, less expensive point of load (POL) converters used in conjunction with the larger, traditional, isolated DC-DC converters,” says Monty Pyle, executive director of sales at VPT, says. “We’ve been asked for a higher current option without the need to waste space and weight stringing together multiple POL converters.”

VPT’s new, 15-amp, radiation-hardened device is the latest addition to VPT’s line of space DC-DC converters, delivers up to 50 Watts of output power, and is qualified to MIL-PRF-38534 Class H and Class K, set by the Defense Logistics Agency. SVGA0515 is “packaged in hermetically sealed metal cases for reliable power delivery through the extreme temperature, shock, vibration, and radiation environments of space travel,” reveals a representative.

Bright future

“There will continue to be a need in the Aerospace industry for rad-hard and rad-tolerant components and systems in the future,” Aeroflex Colorado Springs’ Gonsalves predicts.

Company list

3D Plus

McKinney, Texas

www.3d-plus.com

Aeroflex RAD

Colorado Springs, Colo.

www.aeroflex.com

Aitech Defense Systems

Chatsworth, Calif.

www.rugged.com

ASIC Advantage

Sunnyvale, Calif.

www.asicadvantage.com

Altera Corp.

San Jose, Calif.

www.altera.com

BAE Systems Electronic Solutions

Manassas, Va.

www.baesystems.com/sse

Cadence Design Systems

San Jose, Calif.

www.cadence.com

C-MAC Micro Technology

Great Yarmouth, England

www.cmac.com

Crane Interpoint

Redmond, Wash.

www.interpoint.com

Cypress Semiconductor

Cypress Semiconductor San Jose, Calif.

www.cypress.com

Freescale Semiconductor

Austin, Texas

www.freescale.com

HDL Research Lab

Brenham Texas www.hdlresearchlab.com

Honeywell Microelectronics and Precision Sensors

Plymouth, Minn.

www.honeywellmicroelectronics.com

International Rectifier

El Segundo, Calif.

www.irf.com

Intersil Corp.

Milpitas, Calif.

www.intersil.com

Linear Technology Corp.

Milpitas, Calif.

www.linear.com

Maxwell Technologies

San Diego, Calif.

www.maxwell.com

Mentor Graphics

Wilsonville, Ore.

www.mentor.com

Meggitt Sensing Systems

San Juan Capistrano, Calif.

www.meggittsensingsystems.com

Microelectronics Research Development Corp.

Colorado Springs, Colo.

www.micro-rdc.com

Micropac Industries

Garland, Texas

www.micropac.com

Microsemi SoC Products Group

Mountain View, Calif.

www.actel.com

Modular Devices

Shirley, N.Y.

www.mdipower.com

MS Kennedy

Liverpool, N.Y.

www.mskennedy.com

Northrop Grumman Aerospace Systems

Redondo Beach, Calif.

www.as.northropgrumman.com

paste company name here

Peregrine Semiconductor Corp. San Diego, Calif.

www.psemi.com

Radiation Assured Devices

Colorado Springs, Colo.

radiationassureddevices.com/index.html

Rochester Electronics

Newburyport, Mass.

www.rocelec.com

Semicoa

Costa Mesa, Calif.

www.semicoa.com

Space Micro

Discovery Bay, Calif.

www.spacemicro.com

paste company name here

STMicroelectronics Geneva, Switzerland

www.st.com

Synova

Melbourne, Fla.

www.synova.com

Teledyne Microelectronic Technologies

Los Angeles, Calif.

www.teledynemicro.com

Tezzaron Semiconductor

Naperville, Ill.

www.tezzaron.com

Texas Instruments

Dallas, Texas

www.ti.com

TRAD

Lebarge, France

www.trad.fr

Triad Semiconductor

Winston-Salem, N.C.

www.triadsemi.com

Ultra Communications

Vista, Calif.

www.ultracomm-inc.com

VPT

Everett, Wash.

www.vpt-inc.com

Xilinx

San Jose, Calif.

www.xilinx.com