0.1- and 0.05-inch target connectors for use with spring-loaded pins introduced by Mill-Max

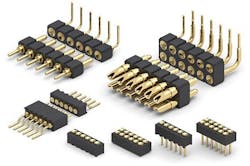

OYSTER BAY, N.Y., 30 March 2016. Mill-Max Manufacturing Co. in Oyster Bay, N.Y., is introducing 0.1- and 0.05-inch target connectors that designers can use in place of SMT pads on a printed circuit board as the mating surface for spring-loaded pins.

The series includes right angle with concave mating face (0.1-inch grid), through-hole and surface mount with concave face (0.05-inch grid), and horizontal surface mount and right angle (0.05-inch grid) with flat and concave face options available.

Combining target connectors with spring-loaded connectors on opposing boards can help make connections between stacked boards or docking stations and devices.

Mill-Max also is introducing two new series featuring targets with concave faces. The single row series is 399-10-1XX-10-007000 and the double row is 499-10-2XX-10-007000; are for through-hole mounting.

The 0.05-inch grid lineup has concave face versions of the SMT and through-hole target connectors: 856-10-0XX-10-002000 (single row, through-hole); 856-10-0XX-30-002000 (single row, SMT); 857-10-0XX-10-002000 (double row, through hole); 857-10-0XX-30-002000 (double row, SMT).

Concave face targets provide additional surface area for mating and can aid in centering/alignment of components and/or boards fitted with spring-loaded connectors.

Rounding out the lineup of new target connectors are right angle and horizontal surface mount (HSMT) versions on 0.05-inch grid. These connectors provide low profile options for parallel or right angle board mating arrangements.

The HSMT version is for daisy chaining applications such as those found in LED strip lighting assemblies. These connectors will be available with flat and concave face options.

The right angle series are 856-10-0XX-20-001000 (flat face) and 856-10-0XX-20-002000 (concave face); the HSMT series are 856-10-0XX-40-001000 (flat face) and 856-10-0XX-40-002000 (concave face).

All the pins are precision-machined and gold-plated for environmental protection, durability and reliable conductivity. The connector insulators are molded from high temperature plastic suitable for most soldering processes, including RoHS environments. All of these products are RoHS compliant.

For more information contact Mill-Max online at www.mill-max.com.