The FCS, the Army’s centerpiece for next-generation land warfare, is to be one of the world’s first truly networked systems, sharing data and sensor information to provide situational awareness all over the battlefield.

By Ben Ames

Vetronics today include the electronic systems on a vehicle that control functions such as navigation, communications, and weapons. Vetronics-short for vehicle electronics-include components from chips and boards to displays and power electronics. Over the years, engineers have honed them to an optimal combination of lightweight and efficient power use, as well as reliable performance.

We now live in an era of change, when designers are binding those separate systems together. The result will be a single web of vetronics systems that can share data among themselves, with neighboring vehicles, and even with nearby soldiers and distant commanders.

Tied into that web will be an array of sensors scattered across the battlefield on infantry soldiers, vehicles, aircraft, maritime vessels, and spacecraft. The data will flow over a wireless, battlefield network, providing every warfighter with the same situational awareness.

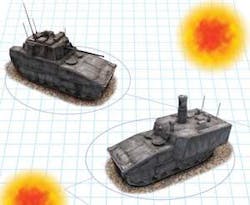

Above Left: Up to 11 soldiers can fit inside the FCS Infantry Carrier Vehicle, depending which version they use: company commander, platoon leader, rifle squad, or weapons squad. Above Right: The FCS Reconnaissance and Surveillance Vehicle (RSV) can deploy unattended ground sensors, a small unmanned ground vehicle, and two unmanned aerial vehicles. The mast holds an electro-optic infrared sensor.

This next generation of vetronics on the battlefield will debut in the Future Combat Systems (FCS) family of vehicles, an array of manned and unmanned vehicles on the ground and in the air, bound by a wireless, distributed network.

An FCS-equipped unit can cooperate with joint forces, be mobile enough to deploy anywhere a C-130 turboprop aircraft can land, and boost its lethality and survivability by striking with indirect engagement instead of direct troop fighting. The key parts of that system include networked sensors tied to nodes on every vehicle that enable all warfighters to see a single, integrated battlefield picture.

Powering vetronics

One of the challenges of networking vetronics systems is managing onboard electrical power, says Ray Carnes, director of command, control, communications, computers, surveillance, and reconnaissance (C4ISR) systems and software integration for the Future Combat Systems Program at Boeing. Boeing and Science Applications International Corp. (SAIC) are co-Lead System Integrators for FCS.

The eight types of manned FCS vehicles-and several unmanned-will use hybrid electric-drive architecture, using a diesel engine to charge the battery that drives their wheels. Electric motors can generate much more torque than internal-combustion engines, and they can enable the vehicle to drive with near silence when it turns off the diesel.

“These vehicles are different from what’s out there now; this will be the first family to be hybrid electric drive,” Carnes says. “Because the C4ISR is onboard, they need sophisticated power management and computing.”

Soldiers in the FCS Mounted Combat System can use its autoloading gun to destroy armored targets up to eight kilometers away

The challenge comes because the vetronics tie into the power-management system. When a commander runs his vehicle in stealthy mode, the system will switch off certain parts of the system to save energy. Depending on the mission, users will load a list of C4ISR priorities into the computer, so it knows which ones to switch off first.

There are many to choose from. Depending on each vehicle’s mission, the FCS sensor suite could include shortwave infrared, uncooled longwave infrared, staring dual-color infrared, multifunction Ka-band radar, nuclear/biological and chemical detector, laser imager, optical augmentation, optoelectronics, night-vision goggles, global positioning system, direct-view optics, and image-intensified charge-coupled devices.

Those sensors are scattered among four types of unmanned aerial vehicles (UAVs), six types of unmanned ground vehicles (UGVs), and eight types of manned vehicles. There is more-Boeing planners say the Future Combat System’s network must link to as many as 20 separate systems. That includes the 18 types of vehicles, the network, and the soldier.

Building the network

Vetronics are a single part of that vast system. As each vehicle operates, it will constantly report variables like its fuel, water, and ammunition supply back to commanders, says Richard Williams, director of Manned Ground Vehicles for the Future Combat Systems Program at Boeing.

To ensure the data gets to the right place, designers are building the network as a distributed web. Every vehicle and every soldier acts as a node on the network, so if any node fails, the data will flow around it.

That is a difficult challenge in itself, designers admit.

“FCS will be the first force deployed that is fully networked, in that all the vehicles and soldiers will be nodes on a wireless network. Putting that network together and establishing data flow is a new step,” says Don DePree, director of the C4ISR Systems Integration Segment in the Future Combat Systems Program at Boeing.

Engineers will use the nascent Joint Tactical Radio System (JTRS) for the job, which is when the JTRS program gets back on track after being restructured; the program today is on hold. The FCS backbone will be the JTRS cluster-one radio and its associated wideband network waveforms. For more localized webs, designers chose JTRS cluster 5 to trade data with foot soldiers, small UGVs and UAVs.

In turn, the data will use the Warfighter Information Network-Tactical (WIN-T) to establish a satellite communications link and send data through the Global Information Grid (GIG) back to commanders in the continental U.S.

Army leaders are eager to get FCS components into the field.

In July 2004, Army leaders announced plans to accelerate delivery of certain FCS systems to the current force. They will use four spirals at two-year increments, beginning in 2008. By 2014, the Army will have one unit of action with all 18 core systems (plus the network), and other modular units with partial capabilities.

Each unit of action will include three FCS-equipped combined arms battalions, a non-line-of-sight cannon battalion, a reconnaissance surveillance and target acquisition (RSTA) squadron, a forward-support battalion, a brigade intelligence and communications company, and a headquarters company.

“The Army is going to modular brigade combat teams, so commonality is crucial,” DePree says. That is why designers will use the integrated computer system (ICS) across both manned and unmanned vehicles.

ICS is a COTS-based system to control sensors, ground vehicles, unmanned aircraft, and handle processing, networking, and data storage. The initial prototype of ICS will deploy on existing Bradley Fighting Vehicles, M1 tanks, Strykers, and Humvees as soon as 2007. To create the ICS, Boeing is working with General Dynamics Advanced Information Systems in Bloomington, Minn., and Rockwell Collins in Cedar Rapids, Iowa.

Computing requirements for vetronics and sensors are different for the various vehicles. Compared to the spacious Infantry Carrier Vehicle, the wired Command and Control Vehicle will have intense computing requirements such as memory and information security.

To make the most of commercial-off-the-shelf hardware, engineers will design the ICS as a hybrid of chipsets, including Intel and PowerPC microprocessors, he says. That diversity is crucial because the ICS must perform a broad range of tasks, from vetronics to battle planning to individual soldier e-mail, and from hard-real-time applications to mission-critical tasks.

Software platforms

Tying all those pieces together is a massive challenge.

“Software integration is the largest job we’ll undertake,” DePree says. Their solution is SOSCOE, the system of systems common operating environment. SOSCOE is a middleware layer that allows diverse software applications to run simultaneously, isolated from each other and from the operating system itself, so designers can add new programs without reconstructing the entire system.

The SOSCOE architecture will use commercial off the shelf (COTS) hardware, and a joint tactical architecture-Army (JTA) compliant operating environment to create nonproprietary architecture for real-time, near-real-time, and non-real-time operations.

“The previous system, FBCB2, is heavily stovepiped, so if we need to recode, we have to throw out the entire module. But a layer within SOSCOE is an OS abstraction layer, so we can even change operating systems as they change,” DePree says.

FBCB2 is force-21 battle command brigade and below, a command-and-control and sensor-fusion network that enables small tactical units to share data in a vertical and horizontal integration of the digital battlespace.

Soldiers will use the FCS Non-Line-Of-Site Cannon for networked, long-range precision attack.

Designers will build the new network with distributed software and processing, to ease the computing load. To manage the large quantity of shared data, they will use a publish-and-subscribe model, where each node publishes its information to the network, but readers receive only the data that matches their role in the battle.

Another way to ease the computing load is to use localized processing, DePree says.

“We’ll start at the sensor end of the network and do compression and some processing. If you just shoved all the raw data out there, it would clog the network. We must manage the allocated spectrum with tools like streaming video, and we rely on quality of service; getting the right data to the right person at the right time.”

Controlling vetronics

A critical vetronics component onboard each vehicle is the Warfighter-Machine Interface (WMI), a computer program with features like: networked warfare functions, unmanned vehicle control, operations on the move, and embedded training with reach-back networking.

WMI is one of four applications within FCS Battle Command software, alongside mission planning and preparation, situation understanding, and battle command and mission execution.

These software displays are tailored to fit each soldier’s role, so the driver of an FCS vehicle will see a 360-degree field of view, augmented reality cues, engine status, vehicle speed, and other gauges. Meanwhile, the vehicle commander will see a three-dimensional map showing threats, friendly forces, terrain, targets, navigation waypoints, and sensor positions. Yet another soldier will use the WMI to monitor the status of caution and warning systems, maintenance logs, and backup displays.

Soldiers leverage the true power of FCS by sharing this rich array of vetronics data. That lets them be more lethal and better-protected by avoiding encounters with the enemy through improved situational awareness, avoiding detection through masking their signatures like acoustic and infrared signals, avoiding signal acquisition with decoys and jammers, avoiding hits with electronic countermeasures, avoiding penetration with better armor and avoiding a vehicle kill with redundant systems.

Migrating to software

That matches a widespread trend of migrating vetronics from hardware into software, says Kelvin Nilsen, chief technical officer of Aonix, in San Diego.

That is true in the commercial realm as well; General Motors says that software accounts for one-third the cost of its cars, and that each car will contain 100 million lines of code by 2010, he says.

“FCS is following that same vision, because software can be more flexible than hardwired circuits, which can fail with temperature or air quality,” Nilsen says.

“Software can provide more capabilities; it used to be all a car did was get you down the road, but now your automobile provides weather, traffic, and navigation. In the military, the vehicle is part of the communication system, which is crucial for IFF (identify friend or foe),” he says.

Likewise, the latest vetronics systems rely on network connectivity off the vehicle. It is true in the commercial world with the subscription OnStar network allowing drivers to request directions or ambulances; it is true in military applications to connect individual vehicles to centralized command and control.

Networking is crucial within the vehicle, too. If part of an FCS platform is destroyed, the vehicle can heal itself and still function, because it relies on multiple onboard computers serving different roles. Each FCS vehicle is built with redundant centers of computation, he says.

Avionics designers use the same approach. “The Navy tells us they have limited space and battery power on a fighter airplane. In the old days, they dedicated one computer for function X and one for function Y. Now, they use a smaller number of general purpose computers, each of which can do any job.”

A fighter jet in a dogfight routes all its computer resources to critical jobs like identifying the target and avoiding incoming missiles. After the fight, the airplane will use those same resources to calculate the best flight path to drop its munitions on a ground target.

Maintaining the FCS

Networked vetronics can also provide great value off the battlefield through improved training and maintenance.

The crews of an FCS-enabled vehicle will be able to train in the same vehicle they will use to go to war. Likewise, they will rehearse for specific missions while traveling to the battle site.

They gain this power because training systems are embedded in the FCS platform, from simulated sensor data and range instrumentation to external training simulations that enter through the network, allowing crews to train alongside other vehicles in exercises such as the Army’s Close Combat Tactical Trainer or Warfighter’s Simulation.

Likewise, networked vetronics will improve each vehicle’s logistics and supportability. Maintenance workers will be able to use more common components, common electrical connectors, embedded diagnostic sensors, easy access to modular components, and repair manuals embedded within each platform. Since each vehicle monitors its own system then shares that data over the network, maintenance crews at the base will be able to predict exactly when a given part will need replacing.

Lightweight vetronics

Vehicles in the Future Combat System will share real-time sensor data and battlefield awareness over the wireless network. But vetronics designers face more prosaic design challenges, too.

Vehicle control itself is localized to each manned ground vehicle, which presents an engineering challenge.

“Fitting into a C-130 is the biggest challenge-we must shrink structures, mechanical systems, and even the engine,” says Ralph Scarantino, common chief engineer for Manned Ground Vehicles in the Future Combat Systems Program at General Dynamics Land Systems Division in Sterling Heights, Mich.

His team was preparing to award a contract by August for the traction drive system, the hybrid electric drive that draws electrical power from a conventional diesel engine, and then uses the electricity to drive the vehicle.

At the same time, they are working with suppliers to develop a new lithium-ion battery. The system needs enough power density to supply 600 volts with 2 kilowatt-hours capacity, in a package of just 350 kilograms weight.

“We will use it for the engine start function and to provide filtering for power distribution-because batteries are essentially large capacitors-for silent drive, and to provide the boost for silent dash,” he says.

FCS vehicles are designed to run with efficient diesel and battery, with just the silent battery, or for a short burst of speed that combines the two sources.

“You would use that extra power if the network tells you a weapon was fired at you and you need to move. The vehicles are specified to 72 kilometers per hour steady state, and to 80 to 90 kilometers per hour for a short duration,” says Boeing’s Williams.

The vetronics designers will save further weight and volume by using their new “power flex bus” for power distribution, Scarantino says.

The unit uses a flat cable instead of round; it acts as a long capacitor with low inductance, offering inherent noise immunity. That is important in FCS vehicles because they create a lot of electro-magnetic inference by using so many electric servomotors.

The unit is a high-density power-distribution device that is MOSFET based, essentially a circuit breaker, he says. It is just one-quarter the weight and volume of the power distribution boxes used on the Abrams and Bradley.

FCS vehicles will use primarily 600-volt cables, with 28-volt units for legacy hardware. Vetronics designers prefer the 600-volt variety, since they can save weight by using high-voltage wires to carry the same power with less current.

RTI builds vetronics network for DARPA Grand Challenge

Engineers at Autonomous Vehicle Systems needed a vetronics network for Flying Fox, their autonomous, unmanned vehicle built on the chassis of a Marine Corps HMMWV. They chose Network Data Distribution Service (NDDS) middleware from Real-Time Innovations, Inc., Santa Clara, Calif. AVS engineers will use the system for synchronized, distributed sensor communications in the vehicle.

Flying Fox is competing for the $2 million prize in the Grand Challenge, a race for unmanned vehicles sponsored by the Defense Advanced Research Projects Agency (DARPA).

The race will be Oct. 8 in the Southwest desert. The team that develops an autonomous ground vehicle that finishes the designated route most quickly-within a 10-hour limit-will receive $2 million. The secret route will be no more than 175 miles over desert terrain featuring natural and man-made obstacles.

No entry finished the last Grand Challenge race. In June, DARPA officials narrowed the field of 118 entries to 40 semifinalists. They will narrow the field to just 20 teams in a September race at the California Speedway in Fontana, Calif.

“We selected RTI because of their proven track record in synchronized, distributed communications and their understanding of the critical design requirements of autonomous vehicles,” says Dan Komaromi, vice president of AVS. “The NDDS architecture makes it seamless to arrange real-time, dynamically configurable communication between multiple vision and laser sensors and the embedded processing modules.”

Autonomous Vehicle Systems is a collaboration between Michigan State University, the University of California San Diego, American Institute of Aeronautics and Astronautics, and industry professionals.

AVS designers use NDDS to network communications between its sensor systems, as they work in various ranges of the electromagnetic spectrum to provide virtual eyes and ears. NDDS also integrates with a modular software system that allows those sensors to be added or removed to fit each mission.

“DARPA and other U.S. agencies are already funding numerous robotic vehicle development programs, and the Grand Challenge is targeted to find innovative solutions that are being tested in realistic conditions,” said Gerardo Pardo-Castellote, chief technology officer of Real-Time Innovations Inc.