By Devon Turner and Martin H. Ettenberg

As warfare modernizes, improving communications, developing more precise munitions, reducing collateral damage, and reducing sensor-to-shooter timelines are critical to ensuring the warfighter’s continued in-theater success. Achieving these goals requires improved pointing, targeting, and designating capabilities, while remaining covert to the enemy and at longer standoff distances than present technology allows.

Indium gallium arsenide (InGaAs)-based shortwave infrared (SWIR) technology is helping to meet these critical goals with advanced solid-state SWIR cameras that can detect most of the lasers in theater.

Laser designation requires precise and direct communication between ground-based and air-based forces at all times in all conditions. The goal today is to reduce the sensor-to-shooter timeline to engage targets quickly, while at the same time reduce fratricide and collateral damage.

The development of laser-guided munitions was the first step in reducing collateral damage and improving weapon precision. In World War II it could take 9,000 bombs to hit a target the size of an aircraft shelter. In Vietnam it took 300 bombs. By the mid 1990s it took only one laser-guided munition (LGM).

LGMs consist of four parts: a computer control group (CCG), guidance canards at the front of the bomb for steering, a warhead section containing the explosives, and a wing assembly at the rear for stability.

A detector at the front of the munition detects the laser and the CCG, then sends commands to the canards to change the LGM’s flight path. Using pulsed lasers and munitions programmed with different frequency codes, multiple targets can be attacked by a single aircraft simultaneously. These weapons can be guided using lasers fired from the same aircraft, a different aircraft, or by ground forces.

One common aircraft-based designation system is Northrop Grumman’s LITENING pod mounted on aircraft like the A-10, B-52, and F-16. The most popular ground-based designating system is the man-portable Special Operations Forces Laser Marker (SOFLAM). Both types of designators/rangefinders use a neodymium-doped yttrium aluminum garnet (Nd:YAG) laser with a wavelength of 1064 nanometers (see photos 1 and 2, page 22).

Because this wavelength is outside the visible spectrum and outside the detection range of night-vision goggles (NVGs), seeing where the laser beam is pointed, or verifying that it is bore sighted with the scope, is challenging at night and even more difficult during the day using currently fielded indium antimonide (InSb)-based systems.

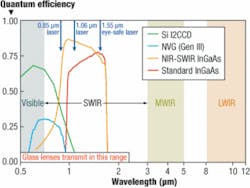

These InSb-based thermal imagers have thinned substrates to aid in detecting light with wavelengths much shorter than are typically detected in its main application of mid-wave IR (thermal) imaging. The thinning process allows the InSb-based systems to detect light down to 1000 nanometers, although the quantum efficiency of these imagers at 1064 nanometers is quite low, approximately 20 percent. These systems also require cryogenic coolers to work properly. This cooling process further requires the use of significant amounts of power and a large form factor. The large power draw and form factor, combined with the high cost of these imagers, makes it difficult for these systems to be widely deployed.

In contrast, indium gallium arsenide cameras operate at room temperature. This leads to a system that draws significantly less power at a much lower cost. InGaAs cameras are able to see the 1064-nanometer laser designators because of the high quantum efficiency at 1064, which is over 65 percent (see chart at left). The cameras are smaller, lighter, and consume less power, while providing improved capability for laser detection. Under identical conditions as the InSb-based systems, not only can InGaAs-based imagers see the laser spot easily, but they can also see the entire laser beam at night. This allows the user to see the target being designated and the person designating the target, thus reducing the chances of fratricide.

To use designating lasers from the air, planes either need to be “talked-in” to targets, given GPS or latitude/longitude coordinates, or shown the location of the target by a Terminal Air Controller (TAC) using an IR marker. In a typical scenario, a ground-based TAC would sparkle a target with an IR marker, which would then be seen by someone in the air. In the past, these IR markers, which are invisible to the human eye, could only be seen with NVGs, and were thus solely used during night operations, because night-vision goggles are unusable during daylight hours. However, recent technological advancements have allowed SWIR-InGaAs cameras, sensitive to light between 700 and 1700 nanometers, to give users the capability to image not only the 1064-nanometer laser designators described earlier, but also the shorter wavelength IR markers traditionally only used with NVGs (see photo 3, page 22). InGaAs imagers were previously restricted to a smaller wavelength range, between 900 and 1700 nanometers. This recent advancement in InGaAs cameras has widened the detection wavelength spectrum and in turn made the cameras backwards-compatible with NVGs, such as the PVS-14. In addition to its other benefits, this also allows pilots and ground troops with NVGs to see IFF (Identify Friend or Foe) tags used by soldiers at night.

A third laser with a longer wavelength (typically 1550 nanometers), is for range-finding on the battlefield. Similar in functionality to radar, these lasers send out a pulse and the detector measures the time for the reflection to return. The time of flight of the laser is used to calculate range to the target. The 1550-nanometer lasers are eye-safe at much higher powers and much closer distances than 850- and 1064-nanometer lasers due to its longer wavelength with the physiology of the human eye. This laser’s wavelength also falls in the middle of the InGaAs detection band. The other advantage of these lasers is that they are undetectable by off-the-shelf silicon cameras or night-vision goggles.

As InGaAs-based imagers become more commonplace in land and air- based systems, one can envision this longer (and more covert) SWIR wavelength replacing the 850-nanometer IR markers and illuminators that can be easily spotted with NVGs.

In addition to the night operations, with the inclusion of appropriate bandpass filter(s) to block light with unwanted wavelengths, these InGaAs imagers can also see marking, designating, and range-finding lasers during daylight hours (see photo on page 23). This new day/night SWIR-InGaAs imaging capability is not attainable with any competing imaging technology while maintaining the imager at room temperature. The ability to see the imagers day and night by ground troops and pilots can significantly reduce the sensor-to-shooter timeline. It allows validation of target designation and therefore supports the rules of engagement. It also supports maintaining the chain of custody through positive target hand over to weapons platform from the original designator. These advances will help prevent fratricide. The ability to see these different lasers under a wider range of conditions (including daytime) has the potential to revolutionize the military’s CONOPS.

In addition to being able to see both types of lasers (IR and designators), shortwave infrared (SWIR) InGaAs-based imagers also have the ability to be used for surveillance during the day and night. During night operations, InGaAs imagers passively image using SWIR photons always available in the night sky. This light source, often referred to as night glow, is available even if there is no moon light available. Also, because these imagers detect reflected light as opposed to emitted light (thermal), the images look similar to a monochrome daytime visible image and can be easily understood.

Devon Turner is an applications engineer and defense specialist with Sensors Unlimited Inc., a Goodrich company in Princeton, N.J. Dr. Martin H. Ettenberg is director of imaging products at Sensors Unlimited. Visit Sensors Unlimited online at www.sensorsinc.com.