Meeting Thermal Management Challenges in Rugged Defense Applications

In the military embedded environment, design engineers looking to maximize advancements in commercial electronic processors face multiple SWaP (size, weight and power) limitations. Specifically, deployed systems need to be placed within small physical areas, be as light as possible, use limited power, and withstand harsh environments including heat, cold, sand and seawater.

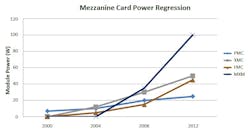

Commercial processors continue to provide more computational power as they follow Moore’s Law trends and exploit architectural advances such as multiple cores. Systems now leverage the latest Intel® and Freescale processors, NVIDIA and ATI GPGPUs, and Xilinx and Altera FPGAs. In addition, innovations around the use of mezzanine cards pack even more power in small spaces. But this does come at a cost: in particular, much higher power draws and therefore higher thermal loads. Figure 1 shows this trend toward higher power.

Figure 1. The increasing power requirements for various form factors.

Board-level heat dissipation is a real challenge for the military embedded system designer. Furthermore, these designers must develop solutions that also meet demanding SWaP requirements. Designers also need to consider more than just board-level thermals; they must consider the overall system, which includes the chassis (fans, sidewalls, etc.) and its surrounding enclosure (e.g., a pod mounted under the wing of an aircraft). This has prompted the need for innovative thermal energy transfer solutions. Another challenge is designing for affordability. In today’s defense procurement environment, there is a mandate to deliver cost-effective systems. So now, designers must simultaneously consider SWaP and cost constraints.

Comparing Technologies

There are several technologies for removing heat from boards and systems, including:

• Spray-cooled

• Liquid-cooled

• Conduction-cooled

• Traditional air-cooled (and it’s variations such as Air Flow Through)

• Air Flow-By™

Both spray- and liquid-cooled techniques are efficient at thermal energy transfer, but they require substantial design complexity, in-field maintenance and can carry serious negative SWaP impacts, resulting from the use of a liquid, pump and radiator. For this paper, we will concentrate on conduction- and air-cooled technologies.

Air cooling is used for many applications. And it works well — until processor technology pushes power and thermal loads above system threshold levels. Under conditions where thermal issues occur, precision clock management can be lowered to reduce heat, but at the expense of reduced throughput. Similarly, conduction cooling works well for certain applications, especially when air flow is limited or non-existent. This cooling technique relies on spreading and transmitting thermal energy by using highly conductive materials in the form of heat sinks, heat pipes, etc. Also, the conduction-cooled technique often is used when a sealed system is necessary.

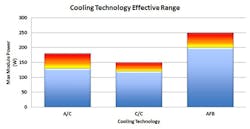

From a systems perspective, both air- and conduction-cooled chassis require filters to protect the electronics from dust and contaminants in the blowing air used to cool the system. Filters require maintenance in the field and add to the overall size and cost of the system. However, Air Flow-By utilizes unique and innovative gasket designs and heat dissipation technologies to provide higher cooling effective range (as seen in Figure 2) without the need for filters.

Figure 2. The cooling capacity for Air-Cooled, Conduction-Cooled and Air Flow-By technologies.

Conclusion

C4ISR sensing systems continue to provide more capability to the warfighter but require significant processing power to convert sensor data to information. There are several cooling technologies that can be used for deployed systems but designers must make choices that balance SWaP requirements with the ability to dissipate heat, particularly as they try to take advantage of advance processor technologies like the Intel server-class chip for embedded systems. Through innovation that leverages a number of disciplines (mechanical, materials, structural, electrical engineering), Air Flow-By provides an affordable air-cooled solution that overcomes the most challenging SWaP constraints.

Watch the interview with Darryl McKenney, Vice President of Engineering Services, as he explains how to tackle heat dissipation in rugged VME and VPX systems.

For more information on Air Flow-By and how it can help increase performance while still meeting SWaP constraints, download the "Innovations in Thermal Management: Air Flow-By" whitepaper.