Electronics cooling moving forward at IBM in attempts to build thermal management into chip designs

WRIGHT-PATTERSON AFB, Ohio, 18 March 2015. Microelectronics experts at IBM Corp. are taking the next step in a U.S. military research program to design convective or evaporative microfluidic cooling directly into microchip designs and packaging.

Officials of the U.S. Air Force Research Laboratory at Wright-Patterson Air Force Base, Ohio, announced a $2.3 million contract Tuesday to the IBM Thomas J Watson Research Center in Yorktown Heights, N.Y., for an application option exercise related to the Intrachip/Interchip Enhanced Cooling (ICECool) electronics cooling program.

The Air Force Research Lab awarded the contract on behalf of the U.S. Defense Advanced Research Projects Agency (DARPA) in Arlington, Va., which is overseeing the ICECool thermal management program.

DARPA awarded IBM a $5 million contract to IBM two years ago for the ICECool Fundamentals program -- the first phase in the project to explore revolutionary new thermal-management technologies for military electronics to help designers make substantial reductions in size, weight, and power consumption (SWaP).

In the ICECool Fundamentals program IBM developed some of the fundamental building blocks of intra- and interchip evaporative microfluidic cooling.

Related: IBM researchers to design liquid cooling directly into microchip designs and packaging

The BAE Systems Electronic Systems segment in Merrimack, N.H., and the Boeing Co. Defense, Space & Security segment in El Segundo, Calif., also are involved in the DARPA ICECool program. BAE Systems and Boeing are working on the ICECool Applications program to find new approaches to electronics thermal-management in military embedded systems and RF MMICs.

For the latest contract, IBM electronics thermal management experts will build on completed research in military electronics to help designers make substantial reductions in size, weight, and power consumption (SWaP) of computer chips, while retaining or advancing chip performance.

IBM will continue searching for ways to shrink chip-cooling technologies such that they can build cooling into the chip itself. The goal is to close the gap between chip and chip-cooling technologies for military electronics like computers, RF transceivers, and solid-state lasers.

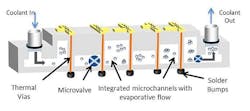

The ICECool Applications program seeks to demonstrate advanced electronics cooling techniques for high-performance embedded computing (HPEC) and RF monolithic microwave integrated circuit (MMIC) power amplifiers with convective or evaporative microfluidic cooling built directly into the electronic devices and packaging.

Related: DARPA releases solicitation for ICECool thermal-management program for embedded computing

In the DARPA ICECool Fundamentals program IBM researchers investigated ways to alleviate cooling limitations of advanced military electronics by integrating thermal management techniques into the chip layout, substrate structure, and package design, not only to shrink on-chip cooling, but also to enhance overall electronics performance.

Essentially, IBM experts focused on ways to make cooling just as important as any other aspect of chip design, and use embedded thermal management to enhance the performance of military electronics. Integrating chips with convective or evaporative microfluidic cooling, DARPA officials say, has the potential to speed the evolution of advanced chip integration.

IBM researchers were to demonstrate chip-level heat removal in excess of 1 kilowatt per square centimeter heat flux, as well as 1 kilowatt per cubic centimeter heat density with thermal control of local submillimeter hot spots with heat flux exceeding 5 kilowatts per square centimeter.

IBM investigated microfabrication techniques to implement thermal interconnects and evaporative microfluidics in several microchanneled semiconductor chips. Company experts considered intrachip cooling with evaporative flows in microchannel flow loops -- either within the chips themselves, or in the microgaps between chips in 3D chip stacks.

Related: BAE Systems joins Boeing in DARPA program to advance electronics thermal management

One fundamental problem that the ICECool program seeks to solve is the large size and weight of cooling subsystems. Ever-smaller chip geometries generate increasing amounts of heat, and the ability to cool electronics is moving more slowly than the ability to shrink chip densities.

This causes some advanced electronics to perform well below the inherent electrical limits of the device technology. Integrating cooling directly into the chip could transform electronic systems architectures and overcome the SWaP bottleneck in advanced electronics, DARPA officials say.

The ICECool program will complement other DARPA thermal-management initiatives, such as the Thermal Ground Plane (TGP) program to develop modern high-performance heat spreaders to replace the copper alloy spreaders in conventional systems; the Microtechnologies for Air Cooled Exchangers (MACE) program to develop enhanced heatsinks that reduce the thermal resistance and power requirements for cooling fans; and the Active Cooling Module (ACM) program to develop miniature, active, high-efficiency refrigeration systems based on thermoelectric or vapor-compression technologies.

For more information contact the IBM Watson Research Center online at www.research.ibm.com/labs/watson, the DARPA Microelectronics Technology Office (MTO) at www.darpa.mil/Our_Work/MTO, or the Air Force Research Lab at www.afrl.af.mil.

John Keller | Editor

John Keller is editor-in-chief of Military & Aerospace Electronics magazine, which provides extensive coverage and analysis of enabling electronic and optoelectronic technologies in military, space, and commercial aviation applications. A member of the Military & Aerospace Electronics staff since the magazine's founding in 1989, Mr. Keller took over as chief editor in 1995.