Technology continues to advance at a rapid pace, putting advanced and wireless electronics in the hands of an ever-increasing number of people – both professionals and consumers alike. Electronic systems continue to grow not only in number, but also in functionality and complexity. At the same time, the size and weight of devices, systems, and components are shrinking, enabling systems integrators to incorporate more and more electronics into virtually every platform.

Technology advancements such as these deliver myriad benefits, but also pose challenges – especially for today’s engineers. The proliferation of advanced electronics and wireless solutions is driving the need, now more than ever, to shield safety- and mission-critical systems from electromagnetic interference (EMI), also known as radio frequency interference (RFI).

| The European Commission's In-flight Lightning Strike Damage Assessment System (ILDAS) measures lightning strikes during flight and relays the data to a ground station, reducing the risk that the aircraft’s next flight is delayed. |

Electronics evolution

“Aircraft are evolving into sophisticated networked computing platforms,” affirms Wally C. Rhines, chairman and chief executive officer of Mentor Graphics in Wilsonville, Ore., “as the aerospace industry moves toward a ‘more electric’ aircraft.”

The modern F-35 Joint Strike Fighter, a fifth-generation, multi-role military combat jet, for example, is five times more complicated than the F-16 military aircraft, first introduced in 1978. “Electrical and electronic content will continue to increase, as will complexity and requirements,” Rhines predicts, “as the industry moves from the ‘more electric’ aircraft to the ‘all electric’ aircraft.”

The complexity and number of electronics in commercial and military aircraft, satellites, and spacecraft will continue into the foreseeable future, as will the amount of electronic and wireless devices used onboard by both crew and passengers. Now more than ever, then, must aerospace engineers adopt effective and efficient EMI/RFI shielding.

Averting interference

EMI/RFI is a very real threat today. More electronic devices are operating in more frequencies than ever before; in turn, systems are more sensitive to noise and interference, posing a challenge for aerospace and defense engineers and driving the need for EMI/RFI mitigation.

EMI/RFI sources are varied, whether natural or manmade, accidental or intentional. Avionics and other electronics on civil and military aircraft, satellites, and spacecraft have succumbed to interference from lightning strikes, solar flares, radiation, and other electronic instruments onboard. EMI/RFI has also been used in various missions and wars to jam radar and communications equipment. EMI/RFI is not limited to outside sources, however; internal interference is a growing concern that calls for printed circuit board (PCB)-level EMI/RFI suppression.

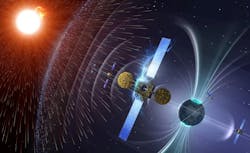

| The space beyond Earth is awash with radiation. Charged particles emitted from the Sun, confined within Earth's magnetosphere or originating from the wider Universe are a major cause of satellite anomalies and malfunctions. (ESA photo) |

EMI effects

Interference, including EMI/RFI from other electronic devices and components, can result in a variety of negative consequences, such as causing safety- and mission-critical systems to malfunction. EMI can degrade cockpit radios and radar signals as well as interfere with air traffic control (ATC) and pilot communications, autopilot and flight controls, navigation equipment, flight deck instruments, and more.

“The key word in all of the above is ‘interference’. The word is important because EMI/ RFI can cause problems with the performance of a variety of electrical circuits, as well as a wide variety of electronic and wireless devices that can include: Wi-Fi performance, radio reception, a wide variety of circuit boards, and wireless phones, headsets, and more,” according to East Coast Shielding representatives in Johnsonburg, N.J. “EMI/RFI signals can cause significant problems – problems that are typically and easily solved through the use of RFI shielding products. “In enclosed spaces such as those used in the aerospace industry, EMI shield solutions are mandatory and rely on highly sophisticated electronic planning and design procedures.”

Aircraft events

Airframe manufacturers, such as Boeing and Airbus, have received many reports from airline operators and pilots related to the onboard use of personal electronic devices (PEDs). Some have shown a strong correlation between PED operation and an airplane anomaly, whereby the problem disappeared when the PED was turned off, returned when PED use resumed, and disappeared when the PED was turned off again.

737 airplane: A passenger laptop computer was reported to cause autopilot disconnects during cruise.

767 airplane: Over a period of eight months, Boeing received five reports on interference with various navigation equipment (uncommanded rolls, displays blanking, flight management computer [FMC]/autopilot/standby altimeter inoperative, and autopilot disconnects) caused by passenger operation of a popular handheld electronic game device.

747 airplane: A passenger’s palmtop computer was reported to cause the airplane to initiate a shallow bank turn. One minute after turning the PED off, the airplane returned to "on course."

EMI effects have resulted in numerous aviation incidents, explains Ed Nakauchi, a technical consultant with Orbel Corp., a provider of standard and custom EMI/RFI shielding components and services in Easton, Pa. As a result, EMI effects are now considered in virtually all aspects of avionics design and certification, he says.

A Northrop Grumman Euro Hawk hangs in the Benefield Anechoic Facility at Edwards Air Force Base, Calif. The unmanned aerial vehicle underwent electromagnetic interference testing to see how it may react to electromagnetic fields in Europe. (Air Force photo by Edward Cannon)

Mitigation methodology

“The electromagnetic waves generated by electronic devices may negatively affect other, similar, electronic devices,” according to a representative of ThomasNet.com, a supplier discovery resource. EMI and RFI may cause malfunctions in electronic devices, such as suppression of signals generated internally in a device, external ambient interference with equipment operation, or emissions generated internally that will interfere with equipment operation. (For more, visit http://www.thomasnet.com/products/emi-rfi-shielding-74850207-1.html)

“The world today is increasingly electronic, with millions of waves and signals floating through the air at any given moment. Therefore, EMI and RFI are potential problems in any industry, and there is a premium on protective products and services from it,” a ThomasNet.com spokesperson adds. “In order to prevent EMI or RFI, EMI/RFI Shielding agents may be used as protection.”

Aerospace and defense engineers are taking measures to suppress or mitigate the threat of EMI/RFI interference, especially in the design, development, and integration of safety-critical systems. Among the most popular methods is EMI/RFI shielding, using solutions that isolate instruments at both the system level and board level.

COTS, custom, and services

A variety of options exist to help shield critical electronics from interference.

“Electromagnetic interference (EMI) shielding issues are commonly encountered by design engineers,” especially related to aerospace, military, information technology, telecommunications, automotive, consumer, and renewable energy applications, say officials at Parker Chomerics, a provider of conductive adhesives, EMI shielded vents and windows, engineered laminates and conductive paints, and EMI gaskets, in Woburn, Mass.

Aerospace industry consultants recommend that engineers and engineering managers insert EMI/RFI mitigation, including the use of EMI/RFI shielding, early in the project workflow. Popular methods include the use of commercial off-the-shelf (COTS) EMI/RFI shielding components, start-to-finish custom components, and various professional services (design, engineering, prototyping, testing, manufacturing, etc.) to help meet application and program requirements.

“Engineers confronted by EMI challenges can avoid delays and cost escalations with upfront planning – and on aerospace and defense projects, that involves EMI/RFI shielding,” advises one industry pundit. Ineffective EMI mitigation, he cautions, can easily translate into added cost and time spent on retrofits, “brute force” shielding, and repetitive prototyping and testing.

It is imperative to consider shielding in the early stages of design, an Orbel official affirms. ”It’s best to prevision for printed circuit board shielding and remove it if it’s not required after compliance testing. There are many ways to get from idea to production. Extensive upfront planning allows for a quicker and cheaper process from beginning to end.”