Thermacore k-Core technology cools NASA’s earth science satellite observatory

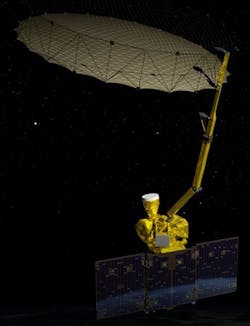

LANCASTER, Pa., 8 June 2016. NASA’s environmental research satellite carries sensitive Soil Moisture Active Passive (SMAP) instrumentation with mission-critical cooling components from k Technology, a Division of Thermacore Inc. in Lancaster, Pennsylvania.

Engineers at the Jet Propulsion Laboratory (JPL), with help from those at the Goddard Space Flight Center (GSFC), manage the SMAP project for NASA.

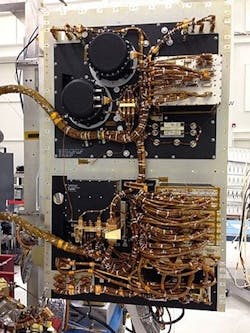

Throughout the SMAP mission, internal heat generated by the satellite’s electronics must continually be rejected into the cold and vacuum of outer space. To meet this difficult thermal challenge while maintaining strict weight and size limits, NASA called upon Thermacore’s thermal management and engineering expertise to develop a unique heat spreader -- also known as a “doubler” -- to cool a critical electronics bus panel.

Instead of using typical aluminum heat-spreader material, the doubler uses k-Core Annealed Pyrolytic Graphite (APG) encapsulated within aluminum to form a composite panel. The six-millimeter thick panel is a sandwich comprised of an aluminum exterior shell that is one-millimeter-thick on each side wrapped around a four-millimeter thick APG core. The advanced APG material enabled the large 0.7-meter long and 0.7-meter-wide panel to achieve a significant weight reduction of approximately 15 kilograms without sacrificing thermal performance.

The hard-anodized plate was finished to support an array of thermal attachment points, thermally and electrically conductive areas, plus grounding areas.

“The complex finishing requirements presented a challenging design. This project involved a detailed mechanical design as well as a finite element thermal analysis to determine component locations and specific geometry of the APG insert within the structure,” says Mark Montesano, vice president of engineering, Thermacore k Technology Division.

In addition to the advanced thermal solution for the SMAP mission, Thermacore will provide a k-Core thermal strap for the thermal clock on the JPL GRACE Follow-on Mission.

Scheduled for launch in 2017, this mission will measure the change in water stored on land from precipitation that has been stored as snow, that infiltrated into the ground or evaporated, or that left the basin as stream flow.

“We are pleased that Thermacore k-Core technology helps to support these vital environmental missions,” says Montesano. “Thermal management is essential to the electronics used on these missions, and we’re proud to help meet their demanding requirements.”

Thermacore’s k Technology division is currently providing APG-based solutions for a number of aerospace, satellite, and military applications.

Founded in 1970, Thermacore specializes in the custom design, development, and manufacturing of highly engineered thermal management and material solutions for a variety of OEM applications across a diversified set of global markets that includes military/aerospace, computer, communication, energy conversion, medical, transportation, test equipment, and automotive. With over 40 years of experience in the design, development, and manufacturing of advanced solid conduction assemblies (k-Core APG system and thermal straps), passive and active two-phase assemblies and systems (heat pipes, vapor chambers, loop heat pipes), liquid cold plates and active pumped liquid cooling systems, cabinet heat exchangers, and custom materials development, Thermacore brings unparalleled engineering design expertise, manufacturing experience, and thermal and material solution performance, quality, and reliability to these markets.

Thermacore employs more than 180 employees at five facilities in the United States: Lancaster, Pennsylvania; Philadelphia, Pennsylvania; Pittsburgh, Pennsylvania; and Ronkonkoma Long Island, New York; and the United Kingdom (Ashington, Northumberland).

You might also like:

Subscribe today to receive all the latest aerospace technology and engineering news, delivered directly to your e-mail inbox twice a week (Tuesdays and Thursdays). Sign upfor your free subscription to the Intelligent Inbox e-newsletter at http://www.intelligent-aerospace.com/subscribe.html.

Connect with Intelligent Aerospace on social media: Twitter (@IntelligentAero), LinkedIn,Google+, and Instagram.

Intelligent Aerospace

Global Aerospace Technology NetworkIntelligent Aerospace, the global aerospace technology network, reports on the latest tools, technologies, and trends of vital importance to aerospace professionals involved in air traffic control, airport operations, satellites and space, and commercial and military avionics on fixed-wing, rotor-wing, and unmanned aircraft throughout the world.