HAMBURG, Germany - Lufthansa Technik AG and Politecnico di Torino, the polytechnic university of Turin, Italy, recently developed an automated, non-invasive diagnostic procedure for the initial examination of primary hydraulic flight control actuators. The aim of the Hydraulic Diagnostics (HyDiag) project, which will run to the end of 2020, is to make diagnoses for these safety-critical components much more precise, to speed up maintenance and to significantly extend their service life.

Since they are constantly in motion during flight, primary fly-by-wire flight control actuators in particular are subject to a very high load. If an error message occurs, they are checked for wear and tear at Lufthansa Technik's component workshops in Hamburg and are readjusted. For this purpose, the actuator in question is first extended and retracted in the test bench following an extensive sequence of individual patterns of movement, while a highly sensitive measurement system records its behavior during this input. Repairs are made wherever the results exceed the tolerances prescribed by the Component Maintenance Manual.

Up to now, this initial test was performed by a mechanic, but owing to human limitations in recognizing errors and making accurate adjustments, this person could only "work by feel" finding individual areas of damage. Many areas of incipient damage remained undiscovered with this approach because they were still within the tolerance limits, but just a short time later, these areas could also trigger a repeated exchange of the actuator. As a result, the actuator's time-on-wing dropped continually with every visit to the workshop.

To prevent this, the automated HyDiag procedure follows a strictly data-centric approach. In the process, the actuator is stimulated during initial examination with an extensive oscillation pattern developed especially for this process. In a fashion similar to a stress ECG, during the procedure the test bench records all the component-specific reactions to this stimulation. The data gained this way is so informative that conclusions can be drawn about the wear and tear of nearly all individual components. As a result, the mechanic obtains a much more comprehensive diagnosis of the wear and tear on the entire actuator system as early as the initial examination, and can focus afterwards on preventing future wear and tear as well. The service life of the component is prolonged significantly as a result. The procedures for stimulating the actuator and for analyzing and interpreting the test results were created in close cooperation with the polytechnic university of Turin, Italy.

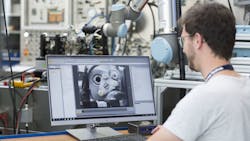

As a second core component aside from the measuring system, HyDiag uses an industrial robot whose software was developed by the Component Services division especially for this task. The robot can carry out all the necessary adjustments during initial examination completely automatically, and in contrast to a human mechanic it does not require special protection when working in the danger zone of a pressurized actuator. Using the data that is recorded, the robot also always "knows" where the optimum for each of the settings lies, and it delivers additional measurement data that has historically not been available for analysis. As a result, the final adjustment of the actuator – the certification test – is also much more precise than it previously was when completed by hand.

All the adjustment tools for the robot were manufactured using 3D printing at Lufthansa Technik's Additive Manufacturing Center. In addition, when producing its findings the new data-based procedure uses all the existing service life data of the actuator in question – with up to 16 gigabytes of data generated by every initial examination. The result is a much more extensive and detailed analysis of the status of the actuator, which permits wear and tear to be recognized and treated very early.

"The automated work process means that devices can be tested faster, more data can be generated, and new diagnostic procedures can be used. That enables us to undertake much more extensive troubleshooting than we ever could before," said Michael Burke, who heads up the HyDiag project for Lufthansa Technik.

"The HyDiag project has a highly innovative content leading to a technological breakthrough in the maintenance of aircraft equipment. Our work together with Lufthansa Technik has advanced the field of Prognostics and Health Management and resulted in multiple papers acknowledged by the community for their quality and scientific relevance," said Professor Giovanni Jacazio, who supervises the activities of Politecnico di Torino on HyDiag.