Pratt & Whitney uses additive manufacturing to repair GTF engines

EAST HARTFORD, Conn. - Pratt & Whitney, the engine manufacturer based in the United States and a subsidiary of RTX, has announced several developments that would improve the maintenance capacity and capabilities of the PW1000G aircraft engine family, also known as the Geared Turbofan (GTF), Rytis Beresnevičius writes for Simple Flying. Continue reading original article.

The Military & Aerospace Electronics take:

9 April 2025 - "A more agile, additive repair process allows us to better serve our customers by improving turnaround time, while reducing tooling costs, complexity and set up," said Kevin Kirkpatrick, vice president of Aftermarket Operations at Pratt & Whitney. "At the same time, it reduces our dependency on current material supply constraints. Additive technology has the potential to support a range of critical GTF part repairs and we're actively working to explore additional opportunities for implementation."

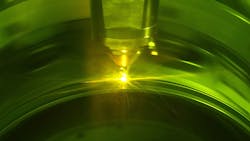

Pratt & Whitney’s North American Technology Accelerator in Florida has developed a new repair method for GTF engine structural cases using Directed Energy Deposition, a form of 3D printing. The process cuts repair time by over 60% by reducing machine changeovers and heat treatment steps. Developed with the Connecticut Center for Advanced Technology and the RTX Research Center, the method will also restore parts worn from normal engine use. In April 2024, Pratt & Whitney announced plans to expand its accelerator technologies to include advanced repairs, digital inspection, adaptive processing, and coatings.

Related: The evolution of 3D printing and additive manufacturing

Related: Military starts to run with 3D printing and additive manufacturing

Related: NASA additive manufacturing project shapes future for agency, industry rocket makers

Jamie Whitney, Senior Editor

Military + Aerospace Electronics