Industry players advance vehicle electronics in an effort to put Future Combat Systems in the hands of current-force soldiers sooner than expected.

By Courtney E. Howard

The Future Combat Systems (FCS) program, the U.S. Army’s largest transformation initiative to date and considered the core building block of the Army’s future force, gained a welcome boost from Army personnel anxious to see advanced FCS platforms fielded in the very near future.

“The future is now,” FCS program manager Maj. Gen. Charles Cartwright said during Experiment 1.1, a live-fire exercise last February in which a platoon of 36 soldiers tested FCS technologies and equipment at the Oro Grande Range at Fort Bliss, Texas. “Networked soldiers already are using early FCS systems.” Various Army personnel tested FCS prototypes in laboratory, field, and demonstration activities during Experiment 1.1, a three-phase, eight-month exercise.

FCS functionality

Phase 1 engineering laboratory events, conducted July 2006 through September 2006 at the FCS System of Systems Integration Laboratory in Huntington Beach, Calif., and at the Army’s Systems Engineering and Experimentation Lab at Fort Monmouth, N.J., tested hardware and software integration, in addition to networking and systems interoperability.

Phase 2 field events in September 2006 through December 2006 at the White Sands Missile Range, N.M., and testing complex in Fort Bliss, Texas, involved the assessment of FCS systems operating in a realistic environment and the demonstration of interoperability between the FCS Class I Unmanned Aerial Vehicle and an AH-64D Apache multirole helicopter.

The non-line-of-sight-cannon (NLOS-C) is the first FCS Manned Ground Vehicle to come out of the FCS program.

Phase 3, spanning January 2007 to February 2007 at the White Sands Missile Range and Fort Bliss test complex, represented the first time soldiers collectively employed FCS systems in a live training environment and used an FCS computer-based training support package. Thirty-six soldiers participated, providing feedback on FCS prototypes and capabilities.

“The new technology is going to save a lot of lives,” Sgt. 1st Class Andres Rugerio, FCS, Evaluation Brigade Combat Team (EBCT) notes. “That’s the thing we’re impressed about.”

The new FCS systems will save lives in combat, say commissioned and noncommissioned officers involved in Experiment 1.1. The systems are expected to increase efficiency, mitigate risks to soldiers, and enable soldiers to make quick, sound decisions on the battlefield. “The bottom line for the combat veterans testing the new systems was that robots, sensors, and information on the battlefield translate to more troops coming home alive,” writes Fred W. Baker III of the American Forces Press Service.

Onward and upward

Experiment 1.1 proved an important step-one likely to bring about the early infusion of FCS capabilities into the current force.

“Experimentation is critical to FCS program success, and most importantly will help enable the early spin out of key capabilities to the current force in 2008,” Dennis Muilenburg, vice president and general manager of Boeing Combat Systems and FCS program manager, explains. “The successful completion of Experiment 1.1 validates the progress and maturity of selected FCS technologies and demonstrated interoperability between FCS and current force systems.”

Soldiers tested such FCS technology as the Non-Line-of-Sight Launch System (NLOS-LS), the Joint Tactical Radio System (JTRS), tactical and urban unattended ground sensors, the Small Unmanned Ground Vehicle, the Class I Unmanned Aerial Vehicle, and an initial version of the network operating system-part of the first FCS capability spin out set for 2008.

Soldiers in FCS Experiment 1.1 use the Small Unmanned Ground Vehicle (SUGV), a man-portable, robotic vehicle developed by iRobot Corporation, for building-clearing operations and to detect the presence of enemy combatants. (Image courtesy the U.S. Army.)

“We’re getting invaluable soldier feedback about what works and what needs improving,” Cartwright explained. “This exercise is further confirmation that the FCS program is working as planned.”

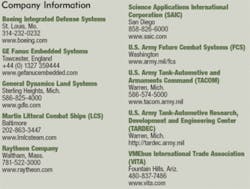

High-level U.S. Army officials must have agreed with Cartwright’s assessment, as they soon contacted executives at The Boeing Co. Integrated Defense Systems division in St. Louis and Science Applications International Corporation (SAIC) in San Diego, the Lead Systems Integrator (LSI) for the U.S. Army’s FCS program. Army personnel authorized the LSI to begin planning FCS low-rate initial production, including long-lead items for FCS Spin Out 1 and early production units of the Manned Ground Vehicle (MGV).

“The Army’s notification to proceed with early production planning is evidence that FCS technologies are maturing according to plan and represents a crucial step toward meeting program production objectives,” Muilenburg explains. “It underscores the accomplishments of the entire FCS One Team, which is well-positioned to deliver these early lifesaving capabilities to soldiers as quickly as possible.”

Spin Out 2008

The LSI team of Boeing and SAIC that is working in partnership with the Army is responsible for total systems integration of the FCS program, including the identification, selection, and procurement of major systems and subsystems. As a result, engineers from Boeing and SAIC have partnered with a large number of military and aerospace industry subcontractors and suppliers, called the “One Team.”

The FCS One Team is working to bring Spin Out 1, the first of three FCS spin outs, to the current force in the next fiscal year. Spin Out 1 will infuse current-force combat vehicles with advanced FCS capabilities, such as enhanced situational awareness and communications.

Soldiers participating in an FCS Experiment 1.1 mock combat exercise use the Small Unmanned Ground Vehicle to clear a building. (Image courtesy the U.S. Army.)

Abrams battle tanks, Bradley Fighting Vehicles, and High Mobility Multipurpose Wheeled Vehicles (HMMWVs) gain technology insertions consisting of an Integrated Computer System, System-of-Systems Common Operating Environment, and a Battle Command and Network Management software and communications system, which includes the Joint Tactical Radio System (JTRS) Ground Mobile Radio.

Spin Out 1 also incorporates tactical and Urban Unattended Ground Sensors and the Non-Line-of-Sight Launch System (NLOS-LS).

NLOS-LS

The NLOS-LS, capable of being mounted in a combat vehicle or used on the ground, provides Army personnel with long-range precision attack capability in a small form factor, enabling quicker, more sustainable deployments. The NLOS-LS is being developed by Netfires LLC, a joint venture of Lockheed Martin and Raytheon, located in Tucson, Ariz.

Engineers at the Lockheed Martin Littoral Combat Ships (LCS) division in Washington commissioned GE Fanuc Embedded Systems, formerly Radstone Embedded Computing, in Towcester, England, to provide the processing subsystem that will control the first spin out of the NLOS-LS.

GE Fanuc Embedded Systems’ SBC340 is a 3U VPX board currently being proposed to an FCS program.

“The NLOS-LS has been selected for accelerated development,” says David Compston, product marketing manager of Defense & Aerospace Products at GE Fanuc. The NLOS-LS combines a common vertical-launch container launch unit (CLU), 15 missile-launch chambers, and command-and-control equipment to support the deployment of the Precision Attack Missile. “The CLU is platform-independent and transportable by truck, plane, helicopter, or ship. It can be fired from a platform or the ground, and can operate in autonomous mode,” continues Compston.

The GE Fanuc processing subsystem selected by Lockheed Martin, in an order worth more than $1 million, incorporates a Compact PCI 6U CP1A single-board computer fitted with an I/O daughter card PMC, a CPX24 rugged managed Gigabit Ethernet switch, and a Radstone multifunction I/O board-all housed in a customized rugged enclosure.

“The product provided by GE Fanuc Embedded Systems for NLOS-LS can broadly be described as commercial-off-the-shelf (COTS),” Compston explains. “Yet, modifications have been made in response to specific customer and program requirements.”

JTRS

BAE Systems engineers in Wayne, N.J., have delivered the first communications payloads, composed of JTRS Ground Mobile Radio Systems, to Boeing for the FCS program. Delivery of the systems is a major step in the Army’s plans to deploy software-programmable radios on current-force Abrams tanks, Bradley combat systems, and HMMWVs.

“Future Combat Systems has moved from delivering design to delivering hardware,” Donald C. De Pree, director of FCS C4ISR for Boeing, says. “It’s an important step toward realizing the promise of FCS by delivering systems that will provide real benefits to our fighting forces.”

During Experiment 1.1, interoperability between FCS and current-force systems was demonstrated when real-time video imagery taken from the Honeywell-developed Class I Unmanned Aerial Vehicle (UAV) was relayed into the cockpit of an AH-64D Apache multirole helicopter during mock combat exercises. (Image courtesy the U.S. Army.)

Engineers at BAE Systems, serving as the FCS communications systems integrator, provide electronic and mounting hardware, radio antennae, and integration services for a complete Ground Mobile Radio system. The Ground Mobile Radio is a family of software-programmable radios designed to provide voice, data, image, and video communications to mobile military forces. The system underwent vehicle testing this past spring, and will be deployed on the Abrams, Bradley, and HMMWV platforms as part of FCS Spin Out 1.

“For the warfighter, this system will provide significantly improved situational awareness and understanding,” Jeff Markel, president of Network Enabled Solutions for BAE Systems in Wayne, N.J., explains. “It will provide the network capability that is the backbone of FCS for both current-force platforms and also for future-force manned and unmanned ground vehicle and unmanned air vehicles.”

MGVs

Army officials flagged early Manned Ground Vehicle (MGV) units, in addition to the various components in Spin Out 1, for early production planning. FCS MGVs are networked vehicles sporting enhanced armor and protection, as well as next-generation survivability and sustainability technologies. FCS calls for a family of MGVs-variations of a single platform based on a common chassis and 70 percent common components.

As part of the FCS One Team, General Dynamics Land Systems in Sterling Heights, Mich., is teamed with BAE Systems in Santa Clara, Calif., to develop and field a family of transportable, deployable, lethal, and survivable MGVs. These next-generation combat vehicles will provide a majority of the firepower in FCS-equipped Brigade Combat Teams and serve as critical nodes on the FCS network.

With commonality and modularity in mind, the MGV team is taking an open-architecture approach to FCS vehicle systems, to facilitate technology insertion and spiral development. The two companies, with LSI and U.S. government participation, are designing and developing a family of eight MGVs featuring a common platform design with common components and subsystems.

Unmanned ground vehicles (UGVs) are currently in development and will be key elements in the FCS System of Systems, providing greatly enhanced operational capability in the FCS-equipped Brigade Combat Teams. (Image courtesy BAE Systems.)

“The FCS Manned Ground Vehicles are the next generation of vetronics,” admits Mary McAdam, FCS communications manager for the LSI at Boeing. “When fielded, they will provide fully networked capability that will provide the warfighter with the ‘see first, understand first, and act first’ capability they need.”

FCS MGVs sport several technological advancements, McAdam continues. “First, they are powered by a hybrid-electric drive propulsion system, making them much more efficient and reducing fuel usage. Second, all sensors, computers, and weapons are designed and integrated from the ground up to enable maximum capability. For example, the FCS network provides information from any sensor on any platform to be exchanged with any other node in the FCS network. Many of the technologies being implemented on the FCS platforms are implementations of systems being developed within the Army and Department of Defense (DoD) development programs.”

The LSI team is preparing prototype units for testing, says McAdam. A Non-Line of Site Cannon (NLOS-C) firing platform has been completed and is in testing. The first NLOS-C early prototypes will be completed and move to test in FY08. The remainder of the MGV variants, 8 in all, will enter testing in FY11. “Prior to that, all subsystems will be developed and tested on their way to being integrated as a full vehicle,” she notes.

MGV protective subsystem

One important MGV subsystem, especially given the increasing use of improvised explosive devices and similar warfare, provides vehicles with reliable protection. Engineers at Raytheon’s Network Centric Systems business in McKinney, Texas, won a $70 million subcontract from BAE Systems, to develop the hard-kill Active Protection Subsystem (APS) portion of the MGV Hit Avoidance System.

BAE Systems leads the hit avoidance integrated product team for FCS MGVs and, with support from General Dynamics, is responsible for integrating the Raytheon-developed hard-kill APS with soft-kill countermeasures, obscurants, and decision-aid software into the overall MGV protection system.

The vehicle suite of defensive capabilities includes soft-kill electronic countermeasures, such as jammers and decoys, and hard-kill counter-munitions. The layered hit avoidance system is designed to provide full-spectrum survivability against rocket-propelled grenades, anti-tank guided missiles, high-explosive anti-tank rounds, top attack munitions, and tank-fired kinetic energy rounds, as well as warfare tactics of the future.

Future vetronics

“The next big thing in vetronics is unquestionably VPX,” says GE Fanuc’s Compston, “and the opportunity for substantially increased processing power in smaller (in size and weight) packages.”

VPX, originally titled VITA (VMEbus International Trade Association) 46, is an American National Standards Institute standard proposed by the VITA Standards Organization in Fountain Hills, Ariz. VPX provides electronics designers with greater flexibility in how electronics are integrated, and are especially useful to vetronics engineers working in compact vehicle environments. In fact, vetronics architectures are expected to change-e.g., reduce in size and complexity-with the adoption of VPX.

VPX merges the latest connector, packaging, bus, and serial fabric technologies, while supporting traditional parallel VMEbus solutions via bridging schemes. “The support that VPX provides for switched serial fabrics enables far more complex, more sophisticated applications to be developed,” Compston explains. “The trend also is toward increasingly autonomous vehicles that are small and lightweight, whether air-, land-, or sea-based.”

null