Military designers are taking advantage of the latest sensor technology and signal processing systems to track and kill incoming enemy missiles.

By John McHale

There are many critics who say that the U.S. military should not be spending so much money and effort on missile defense-claiming lack of a threat and repeated system failures.

Yet North Korea’s recent missile tests prove the threat is not an idle one. The U.S. military needs missile defense systems that handle several threats, and current systems have already begun to show success in destroying these targets.

The key to tracking and destroying incoming missiles is the ability of the sensors networked with high-performance processors to pick up targets moving at high speed. A perfect example of system doing that today is the U.S. Navy and U.S. Missile Defense Agency (MDA) Aegis ballistic missile defense (BMD) weapon system.

The Aegis system has performed eight tests and been successful seven times, says Ken Ross, director of communications for Lockheed Martin, prime contractor for the Aegis BMD. It has shot down targets in each phase of flight from boost phase (ascending) to terminal phase (descending), he adds.

Aegis

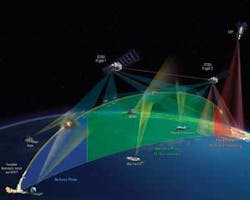

Aegis is the U.S. military’s primary maritime surface defense system and is the foundation for Aegis BMD-the primary component of the sea-based element of the U.S. ballistic missile defense system. The Aegis BMD seamlessly integrates the SPY-1 radar, the MK 41 Vertical Launching System, the Standard Missile-3 (SM-3), and the weapon system’s command and control system. The Aegis BMD also integrates with the BMDS, receiving cues from and providing cueing information to other BMDS elements.

The Aegis primary sensor is the Lockheed Martin SPY-1 radar and Aegis ballistic missile defense signal processor (BSP), Ross says. It is a fixed phased-array antenna with four on each ship all moving simultaneously, he continues. A solid-state radar is planned for a future variant within the next decade, Ross adds.

The BSP, which is in development and will be installed in Aegis BMD ships beginning in 2010, provides an advanced discrimination capability to defeat more complex ballistic missile threats. The BSP can also provide data target data to other defense systems in ground or air that can then take out the incoming threat, Ross says.

The Aegis BSP is an open-architecture design that facilitates quick and affordable upgrades as the signal processor technology evolves. The move to open architecture for Aegis BMD is in parallel and aligned with the Navy’s Aegis Open Architecture (OA) initiative to transform the (non-BMD) Aegis to a fully open architecture system, beginning with the cruiser modernization program now in progress, Ross says. BMD capability will be included in modernized OA Aegis-equipped Ticonderoga-class cruisers and Arleigh Burke-class destroyers starting in 2012, Ross says.

The improved signal processing capability enhances what detail the sensors can pick up on high-speed missiles, Ross says. They went from simply recognizing the missile to differentiating between the missile’s cone and the body, he explains.

Earlier this year the BSP helped track several advanced ballistic missile targets in separate tests off the coast of Kauai, Hawaii. During both events-critical measurements and countermeasures (CMCM)-2A and 2B-the Aegis AN/SPY-1B radar aboard the guided missile cruiser USS Lake Erie (CG 70), augmented by the Aegis BSP, provided real-time detection, tracking, and discrimination performance against threat-representative targets.

“The Aegis systems engineering philosophy of build a little, test a little, learn a lot raises performance expectations with every test,” says Joe Rappisi, Lockheed Martin’s director for Aegis BMD. “Every test pushes the envelope and engages key players at all levels, from the sailors operating the ship to the Navy, MDA, and industry engineers. In these tests, the developmental Aegis BSP demonstrated new discrimination capabilities that will protect our nation, allies, and forces deployed around the world against more complex ballistic missiles.”

Open architecture is the key to the BSP. All of the hardware is commercial-off-the-shelf (COTS) and has an upgrade path. The original UYK-7 and UYK-43 standard Navy computers that originally controlled the system were phased out and “we are now working with state-of-the-art equipment,” Rappisi says. The promise of open architecture is that it makes the hardware independent of the software, he adds.

The BSP consists of many processors in racks of single-board computers running in parallel, Rappisi says. It provides the capability for modular band tracking and synthetic wideband tracking, which could not be done with previous technology, Rappisi says. Initially the processors will use PowerPC technology primarily on single-board computers designed by Mercury Computer Systems in Chelmsford, Mass., says Paul Bertollotti, radar systems engineering manager for Lockheed Martin. The next step will take advantage of field programmable gate array (FPGA) technology, he adds.

The difference between today’s COTS technology and the UYK-7 and UYK 43 computers that originally ran the system is astounding, Rappisi says; it would take thousands of UYK-43s to perform the capabilities of the BSP, he explains.

The CMCM-2A and CMCM-2B tests are part of the MDA’s Critical Measurements and Countermeasures Program-an integral part of the MDA’s test process that provides participants with the opportunity to reduce technical risk by testing against stressing, complex target scenarios, Lockheed Martin officials say.

Ultimately 15 Aegis destroyers and three Aegis cruisers will be outfitted with the capability to conduct long-range surveillance and tracking (LRS&T) and engagement of short- and medium-range ballistic missile threats using the Aegis BMD and the Standard Missile-3 (SM-3). To date, 11 Aegis destroyers have been upgraded with the LRS&T capability and two Aegis cruisers have been outfitted with the emergency engagement and LRS&T capability.

The Aegis system is deployed on 80 ships around the globe with more than 30 additional ships planned or under contract. In addition to the United States, Aegis is the maritime weapon system of choice for Japan, South Korea, Norway, Spain, and Australia. Japan will begin installation of Aegis BMD in its Kongo-class destroyers in 2007.

Standard Missile-3

Engineers at Raytheon in Tucson, Ariz., are developing technology for the U.S. Navy Standard Missile-3 (SM-3) Block IA and to continue Block IB development, leading to sea-based missile defense deployment.

The SM-3 Block IA provides an incremental upgrade to improve missile reliability and supportability at a reduced cost. Block IB incorporates into the kinetic warhead an advanced two-color infrared seeker and a throttling divert and attitude control system providing additional capability against evolving threats.

“SM-3 is an excellent example of spiral development,” says Ed Miyashiro, vice president of Raytheon Missile Systems’ Naval Weapon Systems. “We are focusing on Mission Assurance to deliver near-term capability to the fleet, while we develop and integrate incremental block upgrades to counter the evolving ballistic missile threat.”

SM-3 has transitioned from engineering development to manufacturing build process and is being built along with production SM-2s in Raytheon Missile Systems’ factories in Tucson, Ariz., and Camden, Ark. The SM-3 kinetic warhead (KW) is built and tested at a state-of-the-art kill vehicle manufacturing facility in Tucson, which enables the company to incorporate the best of spacecraft quality and high-rate missile manufacturing expertise. The entire upper stage including KW and third stage also is integrated in Tucson before going to Camden for all up round integration.

Raytheon also designs the Exoatmospheric Kill Vehicle (EKV), which has its own infrared seeker, propulsion, communications, discrimination algorithms, guidance and control system, and computers to support target selection and intercept decisions in the end game of the intercept mission. The EKV is the intercept component of the Ground Based Interceptor (GBI), the weapon element of the Ground-based Midcourse Defense system. The EKV mission is to engage high-speed ballistic missile warheads in the midcourse phase of flight and to destroy them using only the force of impact, or hit-to-kill.

As part of the payload, Raytheon also builds and delivers the booster adaptor, which provides a common EKV interface for both the Orbital and Lockheed boosters. The adaptor provides EKV with power, communication and environmental protection prior to eject.

THAAD

A key element of the nation’s ballistic missile defense system (BMDS), the Terminal High Altitude Area Defense (THAAD) weapon system is a Missile Defense Agency program, with the program office located in Huntsville, Ala. THAAD is designed to defend U.S. troops, allied forces, population centers, and critical infrastructure against short- to intermediate range ballistic missiles. Lockheed Martin is the prime contractor

“The THAAD weapon system consists of four components: radar; a THAAD fire control and communications unit (TFCC); launchers; and interceptors, says a Lockheed Martin official.”The TFCC provides defense and mission planning and communicates with the radar. The primary sensor is the powerful X-band phased array radar that classifies, types, and tracks threats and discriminates objects in its large field of view. Once the THAAD interceptor is launched against a threat, the radar communicates with the interceptor to provide in-flight target updates. The THAAD interceptor’s sensor is an infrared seeker that acquires the threat and fuzes its data with radar data, discriminates, and defeats the threat in the final seconds of the end-game.”

The sensors are networked in the THAAD TFCC via a “two-way communication link to the ballistic missile defense system in order to both pass and receive messages via Link 16,” he says. “The THAAD weapon system can operate in the field autonomously or can provide and accept cues from other ballistic missile defense systems.”

According to the Lockheed Martin official the THAAD development program is progressing well with flight testing that began in late 2005 at White Sands Missile Range (WSMR), N.M. The second successful test followed in May 2006.

“THAAD successfully intercepted a unitary target in July of this year and we were positioned to test against a separating target in September,” he says. “A test anomaly of the target resulted in a No Test for the THAAD interceptor. While range safety constraints did not allow the interceptor to fly, we did received valuable testing data for our radar and fire control components in a more complex scenario than was planned this early in flight testing.

“After the three successful flights at WSMR, the program is proceeding on the plan to transition flight test operations from WSMR to the Pacific Missile Range Facility (PMRF) in Kauai, Hawaii,” the Lockheed official says. “The remainder of the intercept test program will be executed at PMRF where we can fly against more stressful, real-world targets. Today we are integrating THAAD with the range at PMRF and expect to fly our first mission there in early 2007. The program expects to continue flight testing at PMRF into 2009.

Program leaders are working toward manufacturing the first two fire units with a contract start-up anticipated late this year to begin production, he adds.

SBIRS payload

Engineers at Northrop Grumman Electronics Systems sector in Baltimore are contributing to the missile defense efforts in space. They provide the infrared payload, electronics and ground processing for the mission data processor to the Lockheed Martin-led Space-Based Infrared System (SBIRS) High team. SBIRS High is a series of high Earth orbiting satellites whose sensitive infrared sensors can detect the launch of strategic and theater ballistic missiles from space and pass the time and location of launch to battlefield commanders.

SBIRS High works in conjunction with the Space Tracking and Surveillance System (STSS), a constellation of missile tracking satellites capable of performing missile defense, missile tracking, technical intelligence and battlespace characterization. The company’s Space Technology sector is leading the STSS industry team. Electronic Systems will contribute to the systems engineering, ground segment and algorithms. In addition, the sector will be one of two competitors for the sensor payload and ground station data processing program.

The sector also provides space-borne sensing for early warning systems, weather and ground systems that process C4ISR data from space-based platforms for high-priority U.S. government national security programs

Northrop Grumman is also developing the payload for the Defense Support Program (DSP) replacement.

“This fall, the Northrop Grumman-developed C-band radar for the U.S. Navy participated in the successful test of the Ground-based Midcourse Defense (GMD) system, marking the first time a Navy Strategic Systems Program radar has been used by the U.S. Missile Defense Agency (MDA) to optimize data collection and enhance mission success,” says a Northrop Grumman official.

“This contribution was especially noteworthy due to the short time available to bring this radar on-line for the GMD test,” he says. “Within three weeks of a request for additional assets, Northrop Grumman - under the direction of the U.S. Navy Strategic Systems Program Office - relocated the Navy Mobile Instrumentation System (NMIS) C-Band radar from Cape Canaveral, Fla., to California and installed the radar system aboard the Navy ship USNS Pathfinder.

“The ship was then positioned approximately 600 miles off the coast of California to track the interceptor flight,” the official continues. “The radar successfully tracked the GMD interceptor from the point it broke the horizon, throughout separation and intercept. Data is being combined with information from other sensors to provide a thorough analysis to MDA of all aspects of the test to make adjustments to ensure future mission success.”

Boeing Airborne Laser team rolls out modified aircraft and prepares for flight tests

Engineers at Boeing in St. Louis, along with industry teammates and the U.S. Missile Defense Agency, rolled out the Airborne Laser (ABL) aircraft from a modification facility in Wichita, Kan., earlier this fall during a ceremony marking major program achievements on several fronts.

Boeing presented the aircraft to a crowd of hundreds of government customers, industry partners and Boeing employees gathered at its Integrated Defense Systems facilities in Wichita.

The ceremony highlighted the following accomplishments:

- The Airborne Laser team in Wichita fully integrated the Lockheed Martin-designed beam control/fire control system inside the ABL aircraft, a modified Boeing 747-400F. Two solid-state illuminator lasers, which are part of the beam control device, and a surrogate high-energy laser were installed and fired repeatedly at a simulated ballistic missile target. The track illuminator laser is designed to track a target, while the beacon illuminator laser is intended to measure atmospheric turbulence that the high-energy chemical laser would encounter in its path to the target. During the ground tests, results from the illuminator firings were fed back to ABL, allowing the surrogate high-energy laser to shoot down a simulated target. The program achieved most of the objectives of the ground tests and expects to satisfy the remaining ones in the coming months.

- In Wichita, the team, including a Boeing-Northrop Grumman contingent on temporary assignment from Edwards Air Force Base, Calif., added floor reinforcements and chemical-fuel tanks to the back of the aircraft to prepare the jet for installation of the high-energy laser in 2007.

- The team, with ABL partner Northrop Grumman in the lead, completed a significant milestone for the high-energy laser. In California, Northrop Grumman finished ground-testing the optics that will shape the high-energy laser beam and direct it from the laser to the beam control/fire control system. The optics underwent inspection and refurbishment after the laser achieved lethal power and run-times in a ground laboratory in December 2005.

The next major activity will occur before the end of this year. The program will begin firing the illuminators in flight at an instrumented target board located on a missile-shaped image painted on a test aircraft. This activity will verify ABL’s active tracking and atmospheric compensation capabilities.

“This rollout ceremony symbolizes many significant accomplishments,” says Pat Shanahan, vice president and general manager of Boeing Missile Defense Systems. “The collective team has done a phenomenal job integrating the aircraft and demonstrating its capability in ground tests. Now we are ready to go fly. We are ready to demonstrate the aircraft’s ability to close the fire control loop against a flying target. Once again, we made and demonstrated enormous progress toward ushering in a new age of technology, namely directed energy weapons.”

Boeing is the prime contractor for ABL, which will provide a speed-of-light capability to destroy all classes of ballistic missiles in their boost phase of flight. Boeing provides the modified aircraft and the battle management system and is the overall systems integrator. ABL partners are Northrop Grumman, which supplies the high-energy laser and the beacon illuminator laser, and Lockheed Martin, which provides the nose-mounted turret in addition to the beam control/fire control system.