Troops are pushing rugged computers harder than ever, as manufacturers seek tougher display screens, more reliable hard drives, and faster processors

By Ben Ames

As Pentagon leaders push to digitize the battlefield for net-centric warfare, they put more pressure than ever on deployed electronics. Troops carry laptops, PDAs, and tablets into the thick of battle.

This leaves rugged-computer makers struggling to adopt the latest commercial technology for use in extreme conditions.

Consumer hard disks and display screens fail fast when they’re subjected to rugged conditions like desert heat, blowing sand, inadvertent kicks from Army boots, washdowns with hoses, and freezing temperatures in airplanes and UAVs.

Likewise, the latest processors often sap too much power and generate too much heat to run inside a sealed computer module.

Faced with these challenges, many companies decided to merge with others in 2005. General Dynamics C4 Systems in Scottsdale, Ariz. acquired both Tadpole Computer Inc. of Cupertino, Calif. and Itronix Corp., Spokane, Wash.; DRS Technologies Inc. in Parsippany, N.J. acquired Walkabout Computers Inc. of West Palm Beach, Fla.; and Kontron AG in San Diego acquired Dolch Computer Systems Inc. of Fremont, Calif.

Technology forces frequent upgrades

A major challenge for designers of rugged computers is to keep pace with fast upgrades in COTS technology.

DRS Technologies’ C4I Group in Gaithersburg, Md. supplies computers for FBCB2, the Army’s Force XXI Battle Command, Brigade-and-Below program designed to provide situational awareness and command and control to the lowest tactical echelons. The program began with chips running at 500 MHz, now uses 1.1 GHz, and is moving to 1.6 and then 2.2 within a year, says Albert Zimmerman, senior vice president at DRS Tactical Systems, Palm Bay, Fla.

Soldiers in Humvees use DRS rugged computers to communicate through the FBCB2 network.

To fit such fast chips into its power budget, DRS relies on Intel to move its commercial processors into the mobile embedded line, bringing the power and heat down significantly.

Heat is often a sticking point because all the company’s computers are sealed, with no air flowing through. DRS engineers manage heat primarily by choosing efficient processors, and then by venting heat directly to the computer’s metal case.

“All the components are commercial, but we’re always at the top end of the operating range,” he says. “We’ve got some great engineers. To me, it’s black magic how they get the heat out of there, but they keep it running.”

Likewise, the FBCB2 program initially stored data on a six-gigabyte hard drive, and has now graduated to 40-gigabyte drives.

DRS designers already want to migrate to 60- or 80-gigabyte capacity, but are waiting until disk manufacturers fit that storage on a single platter, for greatest reliability. Solid-state memory is still too expensive to be an interim solution, he says.

The display is a third component that demands frequent upgrades. “Screens are a never-ending battle. You buy glass and it’s obsolete in six months,” Zimmerman says.

Customers shouldn’t be fooled into thinking that displays are a simple commodity-DRS engineers coat the glass for better viewing angles and daylight viewability, even as they wait for the commercial market to produce displays in different sizes.

For FBCB2, DRS makes the Applique RVS-330 Rugged Vehicle System, a computer with 1.2 Gigahertz Intel Pentium M processor, a removable 40-gigabyte hard drive, full QWERTY keyboard, and 12.1-inch SVGA display. The Army uses this computer on 27 different vehicles, from the M1 tank to the Humvee, and from artillery pieces to the Bradley.

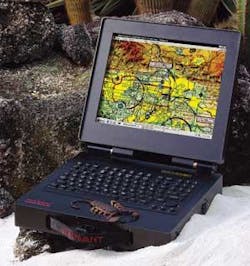

For the U.K. Bowman program, DRS makes the Scorpion Rugged Vehicle Terminal (RVT), a touch-screen tablet computer with 700 Megahertz Intel Pentium III processor, removable 20-gigabyte hard drive, and 12.1-inch SVGA display.

Video demands high performance

One of the fastest growing applications for rugged computers is video, a challenging application with especially high demands for storage, processing, I/O bandwidth, and displays.

Computer designers handle the job with video digitization, compression algorithms, and real-time image processing.

“As compression becomes better, computers can be smaller and cheaper so the military can leverage its expensive sensors and flying cameras,” says Larry Vernec, senior vice president of marketing and business development for L-3 Communications’ Titan Advanced Products and Design Group, San Diego.

Designers at L-3 Titan met the demand with VideoScout. Their first generation product was a large, robust computer that could show video from a Predator or Global Hawk feed, as well as an al-Jazeera or CNN broadcast.

British soldiers use the DRS Scorpion notebook to navigate with their Bowman system.

It was used primarily for Naval special warfare, so commanders in a TOC (tactical operations center) could take a video clip and burn a DVD or annotate a jpeg to pass along to the guys in Humvees, he says.

“Then we made it smaller and lighter by virtue of lighter laptops, for use with Ravens and other small tactical UAVs that the dismounted guys throw over the next hill. They can archive video onto a hard drive, take snapshots, share them, and stream them in real time with small-bandwidth radios running at just 56 kilobits,” he says. It is also used with

ROVER III (remote operations video enhanced receiver), a K/L-band portable receiver used by troops in trucks and Humvees to get UAV data.

The VideoScout is used today in Iraq by the U.S. Marine Corps’ I Marine Expeditionary Force (I MEF) for use with their Scan Eagle unmanned aerial vehicles (UAVs).

Prior to fielding VideoScout, Scan Eagle video data was retained solely at UAV ground control stations, and could not be digitally transmitted to other locations, L-3 says. Now Marine field commanders can distribute intelligent video over tactical networks across the battle space.

Soldiers study Z Microsystems’ Command Console SL, a 1U-tall computer with 19-inch display, watertight backlit keyboard, and trackball.

The VideoScout is available in a 14.3-pound version with 80-gigabyte removable hard drive, or a 9.5-pound version with a 40-gigabyte removable hard drive. Both run Windows XP Pro with a 1.6-gigahertz Intel Pentium M processor and 12.1-inch touchscreen display.

Both have three main components: GETAC W130 ruggedized laptop; L-3 VigraWATCH image processing card, a full-size PCI board mounted in a base unit under the laptop, with sophisticated cooling for compression and decompression, extracting metadata, and Ethernet connections; and L-3 Insyte software used for the touchscreen-based UAV interface, file storage, and image editing.

“Cooling is a challenge while keeping it rugged,” says Vernec. “It can reach 130 degrees inside a Humvee in the desert, and the PC and the imaging processing card generate their own heat. So we use specialized ducts and seals to blow cool, clean air over that card.”

GETAC picks Toshiba

In July, leaders at GETAC Inc., Lake Forest, Calif., announced they would adopt Toshiba’s 1.8-inch hard disk drive for a lighter, less power-hungry rugged system in their W130 model. These 20-, 40-, and 60-gigabyte disks are removable and interchangeable and are more rugged and reliable than 2.5-inch drive counterparts with similar storage capacity, the company says.

The W130 rugged notebook combines ultra-lightweight with strength and durability. It features an Intel Centrino 1.4-gigahertz Pentium Mobile processor, up to 1 Gigabyte of DDR RAM, and a 12.1-inch TFT LCD display, all in a package weighing less than six pounds.

Marines use the VideoScout computer from L-3 Titan to view and share videos from circling UAVs.

Users can choose options like a sunlight-readable screen or touch-screen display. And the W130 provides multiple wireless communications solutions, including IEEE 802.11b/g Wi-Fi connectivity, GSM/GPRS, and DataTAC, which allow access to the Internet through a cellular network.

Its die-cast magnesium-alloy case and shock-protected hard drive enable it to withstand a four-foot drop onto concrete. And users can pick the standard cold-temperature operation at 0°C or freezing operation at -20°C.

Wolverine goes wireless

Another new product in the market is the Wolverine from GE Fanuc Computer Dynamics, Greenville, S.C.

This sunlight-readable computer is HAZLOC approved, with a NEMA 4 environmentally sealed enclosure with corrosion resistance. Based on a single-board computer with an Intel Pentium M 1.6-Gigahertz processor, the unit can be configured with up to 2 gigabytes of DDRAM. The 28-pound Wolverine offers wireless Ethernet through PCMCIA expansion and a field-removable hard drive.

To provide a sunlight-readable display with minimal temperature rise, the 15-inch AMTFT LCD uses passive viewing enhancement filters. And for rugged use, it offers an impact-resistant Near Field Imaging (NFI) touchscreen with anti-glare and scratch-resistant screen.

Fast processors create heat

As troops rely on their rugged computers to do more and more work in the field, they often ask for more powerful processors. They don’t realize that increased power can force design tradeoffs because many rugged computers don’t have access to cooling pipes or clean air.

“Everyone wants higher processing power, but that often creates too much heat, so we have to add heavier heat sinks,” says Scott Kongable, president of Crystal Group, in Hiawatha, Iowa. “They want the dual Xeon for power, but they want it to run at 55 degrees Centigrade, which needs big heat sinks. And that creates an issue with shock and vibration.”

One solution may come from chip makers, as both Intel, of Santa Clara, Calif. (which makes the Xeon processor) and AMD, of Sunnyvale, Calif. have promised to develop more power-efficient, mobile processors.

The Army’s Command Post Platform uses Z Microsystems’ sealed computer modules, shown here in 2x (left) and 4x (right) systems.

In the meantime, Crystal has launched a line of AMD-based computers, responding to a market perception that AMD’s Opteron chips are more efficient than Intel chips, he says.

Another theme in rugged computers is the demand from prime contractors and military specifiers for standard consumer components in customized configurations.

That is an expensive proposition for a rugged computer manufacturer, so Crystal Group has launched the CS100E, a 1U server that is flexible enough to perform storage, processing, or I/O tasks, and rugged enough to meet MIL-STD-810F.

“We used to call it customized COTS, but now we can just configure this server to meet a new form factor, a nonmainstream I/O standard, or a demand for removable storage,” Kongable says.

A common computer for joint forces

Buyers of rugged computers are pushing for net-centric operations across the entire military. They demand a common footprint for computer electronics in the Navy, Air Force, Army, and Marines.

That is a challenge for computer designers because deployed systems require specialized equipment, from software to storage and displays. It is also a challenge because of the fast pace of technology change.

“Every three months a new motherboard comes out, and every four to five months a new display goes away and another one comes out,” says Vladymir Rogov, vice president for marketing and design at Z Microsystems, Inc., San Diego.

“We have to upgrade and refresh while keeping those changes invisible to the user, to avoid new training or procedures.”

Displays change frequently because every mission has its own specifications, from resolution to temperature to EMI (both emitting and receiving).

Customers are demanding a common system that can be rugged, but still fit more information on one display. So displays are getting bigger, to show data from multiple sources, managing real estate on the screen with picture within a picture (PIP) to zoom into one or expand another.

That is the approach ZMicrosystems designers used to supply displays for rugged computers in the Air Force’s RC-135 Rivet Joint surveillance aircraft program. They included custom-programmable, on-screen buttons, so each user could best manage the flood of data.

“The on-the-move world is different from any other world, because people rotate through it. People change, but they want to see the computers, displays, storage, components as one,” he says.

“That’s the difference between deployable, embedded computer sealed inside a tank somewhere and COTS equipment designed for an office.”

Modular computers stay flexible

Rugged computers are getting a serious workout in the field, with many different troops sharing electronic equipment, as the U.S. military stretches its resources to meet demands in Iraq, Afghanistan, and around the world.

“Equipment stays out longer and we rotate people through it faster,” Rogov says. “Ships and planes have longer deployments, and when they do return, they quickly cycle new people through them. Yet each soldier has his personal settings.”

To meet this demand, ZMicrosystems designers created the ZMPU, a multiprocessing unit that can hold from two to seven upgradeable, removable computers in rugged chassis. Each sealed computer module (SCM) is sealed for ruggedness, and heat-sinked to fins for air cooling.

“So you just load a chassis with a new computer for each mission, like a pizza box,” he says. “Soldiers can come back, take a rest, and pick up exactly where they left off.”

Users include: the RC2P program (the Army’s reconfigurable command and control platform, designed by Raytheon), and the A2C2S (the Army’s airborne command and control system). This ground-based or helicopter-mounted tactical operations center, also a Raytheon product, uses a 7x MPU.

Rugged computers shrink to fit

Buyers of rugged computers always ask for the same thing-push the boundaries on size, weight, and power (SWAP).

While these demands are predictable, the applications are not, says Doug Patterson, vice president of marketing and sales at Aitech Defense Systems Inc., Chatsworth, Calif.

The platforms that use these rugged computers in the field change quickly to reflect the latest military challenge.

Today, the Pentagon is accelerating its orders for products that protect soldiers in the field, and delaying orders for long-term development. That means rugged-computer manufacturers are not seeing orders for the Future Combat System, but they are seeing great demand for applications in the shallow-water littoral battlespace, unmanned aerial vehicles (UAVs), and countermeasures to protect ground vehicles from rocket propelled grenades (RPGs) and improvised explosive devices (IEDs).

Consequently, the majority of business is still in the 6U VME space, but there is swelling demand for 3U Compact PCI boards that can fit into small niches on UAVs, he says.

For example, Aitech builds a rugged computer for a system to detect low-flying cruise missiles. In the field, this computer is bolted to the only open space left on a high-mobility multi-wheeled vehicle (HMMWV)-on top of the wheel well.

“So now it gets thermal loading not only from the vehicle, but also solar loading from sitting in the sun,” Patterson says. “These vehicles are packed with electronics, they are hot, and they have no heat exchanger or pipes for liquid cooling. Remember, guys sit inside the vehicle while it’s sitting in the desert, so your box can’t pump out 300 watts.”

Screens dictate computer size

The most frequent points of failure on rugged computers are the screen and the hard drive, says Jim Happel, corporate marketing manager at Grayhill Inc., LaGrange, Ill.

So Grayhill engineers make screens a big part of their design. Instead of just sending a commercial PDA screen into the field, they leverage specialty suppliers of LCDs, then look at the back of the touch-screen, thickness, and material, and chose either chemically treated glass or plastic. They also use index matching and filters for sunlight readability, even with a robust touch screen in front of it.

Even with that process, there will always be design tradeoffs for displays, Happel says.

A screen that can handle the low end of mil-spec temperatures will often fail at the top end. Yet engineers say it is easier to add a display-mounted heater than an air conditioner. So they tend to buy screens that will work naturally in high heat, and rely on the heater in the cold.

Military users do not want to invest in a computer with parts that go obsolete in six months. So Grayhill designers typically choose Intel Xscale processors and the Windows CE operating system.

“Windows CE doesn’t need a hard drive, as Windows XP does. So we can use flash-drive storage, or even the flash on a circuit card, so there are fewer interconnects,” he says.

“Because we’re using Intel and CE, the processor runs cool, with no need for large heat sinks, and the memory can be shrunk down to a really, really small circuit board. So it is typically the display that determines its size.”

The company focuses on touch-screen tablets, PDAs, and vehicle-mounted displays, usually with simple numerical keypads and function buttons, as opposed to the full QWERTY typing keyboard. Grayhill supplies this hardware to integrators such as ITT, Raytheon, Rockwell Collins, and General Dynamics.

null