Systems designers consider a broad landscape of data-storage approaches — ranging from solid-state memory, to spinning magnetic media, to optical storage — for an anticipated avalanche of digital information flowing from satellites and other reconnaissance platforms.

By Ben Ames

The 21st century soldier relies on data to outsmart the enemy before a shot is fired. As a node in the networked battlefield, he taps into a flood of information gathered around the globe.

But even as we collect this surveillance, we face a growing problem — where to store it.

Designers of military systems typically face a choice between rugged-yet-expensive solid-state memory, and fragile-yet-affordable magnetic disks. Recently, however, researchers are questioning those assumptions and are offering designers more choices than ever.

Chalcogenide and holographic memory

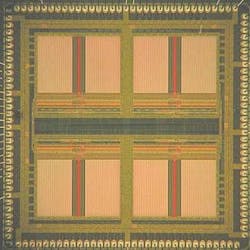

Chalcogenide random access memory (RAM) is a phase-change technology that stores data as bits of either melted or crystallized material. It uses electricity to change each bit, and reads data by measuring electric resistance through it. Researchers at BAE Systems in Manassas, Va. will produce prototypes for space or satellite use by 2004, and will build flight parts by the third or fourth quarter of 2005, says Program Manager Laura Burcin.

Under a grant from the U.S. Air Force Research Laboratory at Wright-Patterson Air Force Base, Ohio, the company has licensed chalcogenide technology from Ovonyx Inc. of Troy, Mich. BAE will build memory storage for the military market, while companies such as Intel and ST Microelectronics have licensed Ovonyx Universal Memory (OUM) for commercial applications.

Engineers favor chalcogenide memory because it is faster than other nonvolatile memory, and because it is inherently resistant to radiation, Burcin says. Satellites need rad-hard memory to store data safely in the harsh realm of space.

Chalcogenide memory is also very rugged; at cold temperatures it will never degrade, Burcin says. That duration drops to about 10 years at a constant 120 degrees Celsius. It also stores memory without need for power. Another strength is endurance. Typical rad-hard memory can run 160,000 to 3.2 million write cycles until it is no longer valid, while chalcogenide can write 512 million times, Burcin says.

Of course, BAE sells memory systems today with current technology, like a 20-megabyte stacked die block with five 4-megabyte SRAM modules. But chalcogenide RAM will open new doors. BAE will fabricate the new parts at its quarter-micron, rad-hard complementary metal-oxide semiconductor (CMOS) plant in Manassas, Va. The company is already planning to build denser memory units when it moves to a 0.15-micron plant.

Sealed, ruggedized hard drives are replacing solid-state memory in some applications. Examples include Mountain Optech products like this 80-gigabyte IDE/ATA drive (above, with playing cards), and 146-gigabyte Fibre Channel Hard Drive (left, inserted into its docking bay).

"Chalcogenide integrates nicely into the CMOS process," Burcin says, adding that designers could use chalcogenide technology to fabricate application-specific integrated circuits (ASICs) as well as field-programmable gate arrays (FPGAs). "You could have a reconfigurable FPGA, that would let you change elements at the last minute before launching a satellite," she says, explaining that this capability could allow scientists at the Jet Propulsion Laboratory in Pasadena, Calif., to reprogram deep-space satellites en route.

When BAE leaders launch the chalcogenide unit, they will compete with other future memory technologies, such as magneto, ferroelectric, and other electronically erasable programmable read-only memory (EEPROM) devices.

"It's a good race out there; there's something new on the web every day," Burcin says. "If you read everything, you'd think it's a neck-and-neck race. But we think we're out ahead, because we're coming out so soon and we're already rad-hard."

The market is packed with current and future technologies. Providers such as Phoenix International in Orange, Calif., M-Systems in Newark, Calif., and L-3 Communications' Targa Systems Division in Ottawa have been supplying rugged bulk memory for years.

The M-Systems solid-state flash family features the Fast Flash Disk (FFD), which Raytheon Systems Ltd. in London picked to provide memory aboard the Airborne Standoff Radar long-range surveillance system — better known as ASTOR. In addition, researchers will soon introduce revolutionary new approaches like holographic memory, now under development by Lucent-spinoff InPhase Technologies of Longmont, Colo., and NASA's Jet Propulsion Laboratory in Pasadena, Calif.

Holographic memory, meanwhile, stores data as light. It is much more powerful than a CD or DVD because it records data throughout the thickness of a medium, not merely on its surface. By varying the angle or wavelength of light, technicians can store thousands of separate holograms in the same space. Finally, it is much faster than current technologies because it reads or writes data in parallel, instead of sequentially. It does this by splitting a laser beam in two — a signal beam (which holds the data) and a reference beam. The beams form a hologram where they intersect in the recording medium. This method could produce incredibly dense storage — InPhase officials predict they could fit 2 gigabytes of data on a postage stamp, 20 gigabytes on a credit card, or 200 gigabytes on a disk.

Engineers at InPhase expect to release their Tapestry 3-D holographic medium for commercial sale by 2005, company spokesman Chris Pfaff says.

Satellites specify solid state

Commercial and military satellites collect great amounts of data as they spin around the Earth, then they store this data onboard until they can beam it back to a waiting ground station.

A typical satellite might carry a rad-hard, solid-state synchronous dynamic random-access-memory (SDRAM) unit, and stack four 256-megabyte modules for a gigabyte of total storage, says Anthony Jordan, director of standard products for Aeroflex UTMC, in Colorado Springs, Colo. But the market is swiftly moving toward much higher densities, he says. Within a year, Aeroflex will release 2-gigabyte and 4-gigabyte memory units, each comprising stacks of four TSOP (thin small-outline package) SDRAM units.

Solid-state memory boasts great endurance because it has no moving parts. With proper isolation packaging and hermetic sealing it can survive the environmental extremes of a rocket launch. But in orbit it is still vulnerable to extreme radiation and temperature change. That is true in any space-based application. Imaging satellites follow a low-Earth orbit, and usually last just five to seven years because of the brutal thermal cycles, he says. Geostationary communications satellites enjoy more stable temperatures at higher orbits, but absorb more radiation over their 10- to 15-year life spans.

The problem is not getting any easier to solve. As chip geometries shrink, it is harder to defend against radiation, Jordan says. "We've come down from 2 microns in the mid-'80s to 0.18 microns today, yet technologies and materials haven't changed much. But now we're starting to see 0.13 micron and even 90 nanometers and below, so materials must begin to change."

That is the reason that many providers of rugged bulk memory use stacked packaging as an alternate way to build denser memory. The method involves piling layers of memory chips on each other in a cube.

Another way to boost memory is to speed the storage rate, which is especially important for satellites that receive or transmit all their data at once.

Aeroflex buys commercial memory units then qualifies them for rad-hard specification. The customer adds his own algorithms, error detection and correction, compression, and data I/O ports, and usually figures out how to get the data in and out of the SDRAM at the card or the box level. Yet Aeroflex planners are moving into this area, too. The company makes a low-voltage-differential signaling (LVDS) serializer/deserializer that can move data as fast as 1.5 megabits per second. For the future, they are now working on a version that is five times as fast, to be used for applications like real-time Earth imaging. That product is about two years from release, Jordan says.

UAVs use disk drives

The U. S. Air Force's C-17 heavy transport plane uses three solid-state memory modules for every flight — a 6-gigabyte video integrated processor for digital terrain mapping, and two 2-gigabyte core integrated processors for general computing. Both memory units are solid-state flash memory cards from SEAKR Engineering Inc. in Centennial, Colo., says Randolph Twogood, the company's director of military electronics.

SEAKR engineers designed their nonvolatile VME product family for military applications, with cards ranging in volumes from 1 to 24 gigabytes. But recently, they have seen a change in the marketplace.

"We have begun to see an evolving market in high-capacity data storage," Twogood says. "We're seeing sensor systems delivering data at gigabit rates, so data storage requirements are becoming horrendous. We're seeing the need for terabyte-range memory."

The U.S. Air Force's C-17 transport planes depend on avionics including three solid-state memory modules from SEAKR Engineering Inc., used for tasks like digital terrain mapping.

Much of that pressure comes from designers of unmanned aerial vehicles (UAVs) who are trying to reduce the cost of each flight by extending memory capacities, he says. Yet as data rises to terabyte levels, solid-state memory becomes too expensive, forcing designers to use heavily ruggedized magnetic disk drives. So in September, SEAKR launched TERA-Brick, a hermetically sealed disk module that is rugged enough for applications in a sonobuoy on the ocean surface or a high-altitude airframe; it offers bulk storage for low cost, he says. SEAKR will build them in memory ranging from 400 gigabytes to 1.6 terabytes, using stacks of 200-gigabyte drives.

Each TERA-Brick uses the ATA interface, with four buses coming off the unit. SEAKR engineers are already planning the next step; when Serial ATA is more widely accepted, they will use as many as eight interfaces per unit; that would boost throughput capacity above

200 megabits per second. ATA stands for Advanced Technology Attachment, which is an IDE Interface for IBM-PC/AT & compatible computers.

TERA-Brick, however, is not the perfect solution. "Even though it solves the cost problem, there's another issue with using magnetic disks to store military sensor data," Twogood says. "Disk drives have an issue with secure erasure." Volatile memories such as SRAM or DRAM lose their contents when the drive loses power, yet nonvolatile memory like flash requires execution of an algorithm to erase content securely.

A memory that stays put is a problem, for example, when a U.S. Global Hawk UAV goes down in Afghanistan, or a P-3 spy plane goes down in China. In both those recent events, the military lost valuable data when other countries seized the disks before they could be scrubbed clean.

The problem gets much easier to solve when the disk is aboard an unmanned craft, he says. SEAKR engineers are now working on a self-destruct solution.

Sealed disk drives

Solid-state memory works well for rugged, small-capacity jobs like placing a 3-gigabyte card on a helicopter. But it is too expensive for applications that need a lot of memory, says Rod Copeland, director of operations at Mountain Optech in Longmont, Colo.

Rugged, high-capacity memory represents a fast-growing market as the U.S. military increases its use of airborne reconnaissance. Sensors that soak up vast amounts of data need a place to store it, yet a 40-gigabyte solid-state drive could cost $20,000, compared to just $2,000 for a similar hard drive, he says.

The solution is hermetically sealed hard drives, custom-ruggedized for each application, but this is a tough job, Copeland warns. Engineers at Mountain Optech see three main hurdles to keeping magnetic disks spinning safely in tough field conditions such as the Army UH-60 Black Hawk helicopter or Air Force F-16 jet fighter.

Chalcogenide memory stores data as bits of either melted or crystallized material. Researchers at BAE Systems have built this test chip in a wire-bond package to demonstrate several independently accessible 64 and 32 kilobit memory arrays with read and write circuitry.

Mountain Optech designers start with the most rugged disk they can find from a commercial manufacturer, and tune that disk's isolation system for each given application. Helicopter rotors create resonant frequencies that can knock a spinning hard drive off kilter, and fighter jets generate different frequencies, as well as tougher G-forces. Then they need to keep it hot; solid-state cards can switch on instantly in cold weather, but a hard drive needs warm-up time.

Finally, designers seal the hard drive. A standard hard drive will work in altitudes only as high as 20,000 feet; after that the thin air cannot hold up the reading head as it spins microns above the memory surface. Even at lower altitudes, salt, fog, or sand can destroy a delicate disk. Yet hermetically sealed disks will work at altitudes as high as 80,000 feet.

Mountain Optech engineers have solved typical hard-drive problems with products like the STRS-146000 Wedgetail, a removable, 146-gigabyte Fibre Channel hard drive; and the SES-80000 IDE/ATA HDD, an 80-gigabyte IDE/ATA drive. They plan to release a sealed 300-gigabyte version this February; placing eight of those in a redundant array of inexpensive disks (RAID) rack would create a rugged and inexpensive 2.4-terabyte-memory module, Copeland says.

Fast interfaces

New military applications are pushing demand for bulk memory products more quickly than technology can keep up; memory providers, therefore, are using the latest networking topologies to handle the load.

"Disk drives are not experiencing any dramatic performance enhancements in terms of data transfer to the medium," says Tom Skrobacz, vice president of business development at Conduant Corp. in Longmont, Colo. "There hasn't been an important improvement since the advent of the desktop disk drive. Capacity is rising, but not by performance of the medium. The only way we get faster is using multiple disks."

So the memory industry is moving from parallel to serial ATA drives, he says. Computer designers today can link 16 drives to one board. With serial ATA, they could reach 32. And that number could grow even larger if they find a way to feature more than one drive on each interface cable.

Driving this growth are data-storage demands for applications in radar, signals intelligence, video, and radio astronomy, he says. Such tasks can collect data so quickly that some Conduant customers use several different products to boost data-transfer rates from a typical 200 megabits per second to as fast as 1 gigabit per second.

Disks running at 200 megabits per second could record the entire Encyclopedia Britannica in 5.12 seconds, or the 20 million books (20 terabytes) in the Library of Congress in 29 hours.

Conduant achieves that speed with its Big River recorders, which use the company's StreamStor PCI, CompactPCI, and PXI disk controllers. Conduant designers build fast, hard-disk-based, long-duration recording and playback systems using IDE instead of SCSI.

What is the secret of their speed? StreamStor is designed to avoid its host computer's processor by using the PCI bus instead. "The typical RAID optical- disk-based memory system is under control of the operating system, which is slowed by bottlenecks such as files and software-level controls," Skrobacz says. "So we throw the nondeterministic events away, and create a hardware pipe."

For instance, the TK200 is a Big River product that specializes in long-duration recording on airplanes. It includes a chassis with two eight-drive modules that record in an alternating pattern called "pendulum mode," so a user can swap out full disks without missing any data.

Applications in homeland security also continue to demand ever-larger memory storage for high-speed recording, as some cameras and radars are pushing toward data rates as fast as 1 gigabit per second. "The media isn't really the bottleneck; the ultimate bottleneck is the interface," he says.

This growth cannot continue forever. Soon, new memory technologies will boost performance even more.

"Looking out onto the horizon, holographic, optical, tape, and magnetic media are the four technologies that are continuing to plow forward as we consider how to handle the growing amount of media," Skrobacz says. But do not expect any changes in the immediate future. "Projections for holographic memory don't begin to approach magnetic in the next-five-years time frame."

Networked storage shares the load

But who says all your data must be stored in one place? Planners at the U.S. Department of Defense (DOD) are trying to save money as they handle huge amounts of data, ranging from simple administrative traffic to vast amounts of satellite images and sensor data.

Until now, that approach has called for consolidating servers within a base or camp. But since the Sept. 11 terror attacks, DOD planners have worried about placing so much critical data in a single location.

Eight of the U.S. Air Force's nine major commands use products from EMC Corp. in McLean, Va., to create networked storage that can hold the same data in two different locations, says Steve James, EMC's business-development manager. Having constant data backups also guarantees continuity of operations (COOP), a major military goal. In fact, DOD planners are already building infrastructure for such a plan called the Global Information Grid Bandwidth Expansion (GIG-BE), he says. Global Grid seeks to lay large-bandwidth data pipes to 92 bases worldwide.

The challenge is doing simultaneous updates and information security at both sites. So today, the Air Force uses networked storage just for business functions such as e-mail, Web, file, and print, James says. EMC designers are building solutions to handle command, control, communications, computers, intelligence, surveillance, and reconnaissance (C4ISR) for the five air-operation centers.

On the ground, the best choice is magnetic ATA drives instead of tape. The disks are networked instead of mothballed, and last longer than tape spools. And data-transfer speed will increase over the next two years from 150 to 600 megabits per second, says Don Martin, an EMC technical solutions manager.

Commercial versions of those spinning disks are too fragile for mobile use in aircraft or on the High-Mobility Multipurpose Wheeled Vehicle, or HMMWV, so EMC engineers are qualifying their Clariion drive for military specification.

Several branches of the U.S. military have already installed networked memory storage systems for applications on bases.

The American Forces Information Service (AFIS), part of the Office of the Secretary of Defense, organizes large amounts of visual data. Prime contractor TranTech Inc. of Alexandria, Va., solved the problem by buying 40 terabytes of storage space from EMC in Spring 2003. Called Centera content-addressed storage, the system uses networked ATA drives to handle huge quantities of information. EMC planners expect it soon to reach 100 terabytes.

AFIS uses this Visual Information Management System (VIMS) to capture, edit, and share data, including photos, video, audio, graphics, and text. Initial users include the Defense Visual Information Center, the Joint Combat Camera Center, and the Joint Visual Information Services Distribution Agency. After a seven-month trial, it will open to all DOD branches.

Army National Guard leaders also were struggling to handle their data. In August 2002 they asked prime contractor Northrop Grumman to help the National Guard focus on warfighting rather than on administration. In turn, engineers at Northrop Grumman's Information Technology division in Herndon, Va., chose EMC Symmetrix Enterprise, a 200-terabyte networked storage system. It includes 54 storage area networks in National Guard data centers throughout the U.S. It leverages that wide reach to streamline personnel records management, finance, logistics, contracts, and e-mail.

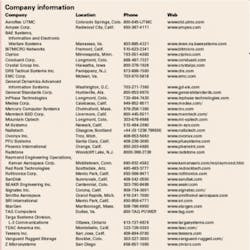

Company information

null