By Ben Ames

Demands for light weight, low power, complex graphics, and a broad range of light intensities to accommodate everything from sunlight readability to night-vision goggles are sending military displays where no screen has gone before.

Displays are everywhere in the 21st century military — from the one-inch-square displays on soldiers' helmets, to four-inch displays on crowded control panels, to 20-inch panels in tactical operations centers.

Designers used to specify cathode ray tubes (CRTs), but now use liquid crystal displays (LCDs) for almost every application. Most say new technologies like organic light emitting diodes (OLEDs) or digital light projectors (DLPs) will eventually succeed, but are still years from widespread use.

So what is so special about LCDs? Military users demand displays that are inexpensive yet tough enough to stand up to conditions like wrench-drop and boot-kick tests.

At the same time, however, they have to be more than physically tough; displays must meet demanding military standards, shield against emissions of electromagnetic radiation, protect power-supply lines, manage thermal emissions, pare weight down, and keep power efficiency up.

Once they have done all that, displays must boast top performance in a huge variety of conditions. Displays designed to operate outdoors must be visible by day but nearly invisible at night; displays that individual soldiers carry must be lightweight and flexible; and displays for command-and-control rooms must have great size and resolution.

null

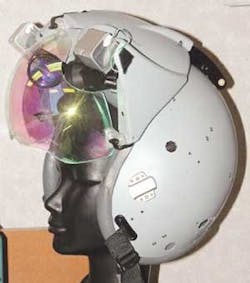

A pilot tests the helmet-mounted display (similar to the prototype at left) and head-down display in a flight simulator for the the F-35 Joint Strike Fighter. Kaiser Electro-Optics and Vision Systems International make both displays for prime contractor Lockheed Martin. Barco View makes the large screen on the wall outside the cockpit.

null

Faced with such tough demands, system integrators tend to buy commercial off-the-shelf (COTS) displays, and then design ruggedized enclosures to meet the military specifications.

Designers do this partly to meet the Pentagon's demand for open-systems standards, but mostly so the contractors can avoid the prohibitive expense of designing new displays for a market as relatively small as the military, explains Bob Pinnel, chief technical officer of the U.S. Display Consortium in San Jose, Calif. The U.S. Defense Advanced Research Projects Agency (DARPA) in Arlington, Va., and industry groups created this consortium in 1993 to boost domestic manufacturing of flat-panel displays.

"The solution for direct-view displays in military implementations today is almost exclusively LCD," Pinnel says. The inorganic LED was once a competitive technology, as developed by companies like Planar, Luxell, and Sharp. Today, however, their availability has been declining, and their performance has not kept pace with advances in LCD technology, he says.

Three screens in the Stryker

For instance, the Stryker Mobile Gun System from General Dynamics Land Systems in Sterling Heights, Mich., uses an LCD display from Raytheon Electronic Systems in Dallas, and two from General Dynamics Canada in Ottawa. They perform three different duties, but designers say LCD is the best solution for each.

The Stryker family of eight-wheel-drive combat vehicles, which is based on the LAV (light armored vehicle) chassis, is one facet of the Pentagon's push to transform the U.S. Army into a force that is deadlier, more mobile, and uses fewer soldiers than today's Army. The mobile gun system variant of the Stryker has a stabilized shoot-on-the-move low-profile turret armed with a 105 mm cannon and a .50 caliber machine gun. Curtiss-Wright Corp's Vista Controls in Santa Clarita, Calif., supplies the vehicle's automated ammunition loading and replenishing system. Army trainers at Fort Lewis, Wash. are now equipping a brigade to deploy to Iraq.

The Raytheon display is a 10.4-inch, glass-front, ruggedized COTS LCD called a Drivers Vision Enhancer (DVE). Stryker drivers use the screen to steer the vehicle, so it not only must refresh images in real time, but also work in the occasional total darkness of a combat vehicle hull.

"We need to make it work with low visual emission and high contrast; you can't emit any stray ambient light or else you're a target," says Dan Dyring, program manager for drivers vision enhancer programs at Raytheon's offices in Dallas. "That's a big contrast to fighter aircraft where sunlight brightness is the challenge."

And yet it cannot be too bright; soldiers in the vehicle often wear light-amplifying night vision goggles, which boost available light hundreds of times. "If you look at an LCD panel, you'll get a huge input of ambient light that just blows you away," he says.

So Raytheon engineers picked an active-matrix LCD with backlight, ruggedized for vibration. Raytheon integrates the system with cables and adaptors for each vehicle. L-3 Communications in San Diego supplies the display device, using LCDs from NEC.

It has been a successful combination. Leaders of the U.S. Marine Corps chose the same display for 3,000 vehicles in their combat vehicle fleet in Iraq, and other branches use it in HMMWVs, LAVs, AAAV (advanced amphibious armored vehicles), and M1 main battle tanks. Raytheon even sells a similar technology as a safety aid (not for driving) in commercial cars from Hummer, Cadillac, Volvo, and BMW.

Raytheon engineers say they hope to improve future versions of the DVE display by adding peripheral vision cues — perhaps by using a high-resolution LCD to show distant objects as slightly out of focus.

They also want to boost reliability, by getting away from the inherent lifetime limitations of the LCD and backlight combination, Dyring says. One option is to use an OLED instead, such as those fitted to Nokia cell phones today.

Five years down the road, Raytheon planners say they want to offer three-dimensional, goggle-less driving displays. One possible technology to achieve that would be DLP — short for digital light projection from Texas Instruments in Dallas. DLP, an integrated circuit-based device with very fast pixel-painting, is used in some high-end televisions.

Tough demands drive Stryker display design

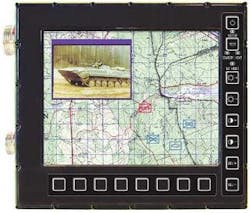

The two other Stryker cockpit displays are 10.4-inch, active matrix LCDs from General Dynamics Canada. One is a monochromatic screen for the commander to view thermal imagery, and the other is a full-color screen for the gunner to use for fire control.

One of the toughest challenges in building displays is such a diversity of uses, says John Thomas, manager for display technology development at General Dynamics Canada. Displays must show information such as roads, thermal signatures, and targets. And they must constantly improve to meet customer demands, such as wider viewing angles, stricter infrared emission control, and a broader dimming range.

Commercial LCD producers such as Sharp and NEC are good at launching new designs quickly. That market pressure is one reason that most military contractors pick LCDs instead of OLEDs, which do not yet have enough market pressure to evolve as quickly, he says.

One of the toughest requirements is designing displays for use with night-vision goggles (NVGs), says Chris Chance, manager of business development for vetronic systems at General Dynamics Canada.

Even though a soldier wearing the goggles would never look directly at a screen, the light-amplifying lenses would blind him if he even glanced at it by mistake. So the latest displays must offer great dimming capability.

A typical commercial display offers a 6:1 ratio between its brightest and dimmest radiance, Chance says. But a military LCD must offer at least 1,000:1, so it can handle the range of conditions from full sunlight to the shade of an enclosed tank hull to nighttime operations. Blackout switches and color filters are other techniques for making LCD displays safe for use in an NVG environment.

Likewise, display engineers can change a screen's cell structure to offer wider viewing angles. For example, moving from a standard compensated TN (twisted nematic) structure to an in-plane switching structure will improve viewing angles. But these improvements come at a cost: lower light transmission demands extra backlighting, which taxes battery power and produces heat.

Another customer demand is size. A perennial challenge for display designers is how to give customers large viewing areas, while conserving space so soldiers can maneuver in a cramped cockpit.

One solution is to combine displays with computers. "Aside from having displays just to look at, customers want displays to be smart, too," Chance says. That also lets designers combine different types of displays, so one user could see a video feed from an external sensor as well as sophisticated graphics.

Such combined solutions are also helpful in meeting the most stringent electromagnetic interference (EMI) shielding requirements. For instance, displays running classified data often need Tempest shielding to prevent spies with radio transceivers from eavesdropping on their signal emissions. Fewer displays means fewer enclosures to shield.

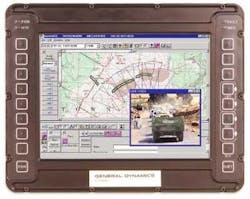

null

The Stryker and Bradley vehicles use displays similar to this 10.4-inch active-matrix LCD (above) from General Dynamics Canada. The "Smart" 8.4-inch version (below) has a Pentium processor built into its casing.

null

But users want more intelligence than that; they want a display to do more than simply show data. "People want more than one way to communicate with the screen," Thomas says. "So we give them programmable keys, touch screens, pointing devices, voice-command, and speaking."

Building touch-screen displays for battlefield use is difficult because the environment is so dirty. Designers must build a screen that resists accidental triggers from dirt, crawling insects, bumps and nudges, water hose wash down, and electrical noise, he says.

New applications for General Dynamics' touch-screen displays include battlefield awareness applications like the FBCB2 (force 21 battle command brigade and below) program, and the Canadian army's Situational Awareness System (SAS).

Another way to get around those challenges is to make a display that can follow vocal commands. That could also help streamline the workload for crews that are growing smaller in number. And if the displays could talk back to their users, the displays would be more useful in providing a direction along with a warning siren — so a pilot would know instantly where the threat was.

But the job may soon get even harder, Thomas says. The supply base has changed sharply over the past 18 to 24 months, as Japanese display manufacturers such as NEC have changed their focus from high-volume commercial products — like laptops — to industrial products, he says. In turn, COTS display manufacturers in Taiwan, China, and Korea have begun to replace them.

LCD powers helmet display in JSF

When engineers at Lockheed Martin started designing the helmet-mounted display (HMD) for the F-35 Joint Strike Fighter (JSF), they had a long list of demands.

The accuracy had to be three times better than relatively old fighters. The vision had to improve from monocular to binocular, yet still shave weight. The center of gravity also had to improve so it could fit everyone from 103-pound women to 245-pound men.

The designers could not meet the challenge with existing technology, so they looked elsewhere.

"Today's legacy helmets are all CRT, but we're going to LCD," says Thomas Frey, pilot systems IPT (integrated pilot team) lead, at Lockheed Martin. "We're integrating the helmet shell with the display, so that is a new opportunity to redistribute components. We're putting some in the back of the helmet, which helps us improve fit, comfort, and balance."

The design calls for a 1280-by-1024-pixel resolution screen, projected off the helmet visor, that can display a range of inputs, including symbology, synthetic imagery, and night vision.

The improvement in accuracy is crucial because a pilot sees symbols positioned over points in space, placed by the avionics tracking system for fire control.

"It's a virtual HUD [head-up display] on an HMD, so we had to come up with a helmet system comparable in accuracy to a HUD," Frey says. "It shouldn't matter if the symbol the pilot sees is reflected off the combiner glass of his HUD or the visor of his helmet, so long as it's in the same position in space."

Lockheed Martin's HMD contractor for this job is Vision Systems International (VSI) in Yardley, Pa., whose officials in turn chose Kaiser Electro-Optics (KEO) in Carlsbad, Calif. The helmet is scheduled for flight trials in November or December.

Lockheed Martin engineers also designed a heads-down display for the JSF cockpit. When they looked at the list of demands, engineers realized they would have to innovate a new technology.

So they combined most of the screens and gauges in an old cockpit onto one color display surface measuring 8 by 20 inches. Illuminating this large screen are two independent rear projectors, not unlike the DLP or Proxima projectors in corporate conference rooms, Frey says. Kaiser also makes it.

"We selected rear projection technology for affordability compared to LCDs," he says. "LCD performance continues to improve, but we had a challenge finding a commercial source to last over the life of the airplane. And OLEDs aren't there yet."

For gross control, the pilot uses voice control and touch-screen buttons, each at least one inch square. The touch sensors are infrared, though designers may use photo-optical sensors in future versions. For fine control, the pilot uses a throttle-mounted controller.

New lights brighten LCD displays

LCDs traditionally have used small fluorescent tubes as their light sources. Those required high voltage, warm-up time, and gentle handling so the glass would not break. And their average 8,000-hour lifetime drops to virtually nothing when operators switch them on in cold weather.

Now there is a better way, says Robert Atac, vice president of military aviation for CMC Electronics in Sugar Grove, Ill. CMC acquired the former Flight Visions Inc. in 2002.

CMC engineers have qualified an LED-backlit LCD for heads-down cockpit displays in the CP140 Aurora (the Canadian version of the P-3 maritime patrol aircraft), midlife upgrades for the Tornado fighter/bomber, and the KT1 and T6 trainers. The screens will also soon be approved for some helicopters.

The new lighting boasts many advantages, Atac says. It runs on low voltage, has rugged solid-state construction, and switches on instantly in any temperature. In addition, it claims a 50,000 to 70,000-hour lifetime, and lists comparable weight and cost to older displays.

An additional improvement is brightness, which is crucial for daylight viewing in airplane applications. The new LCDs can run at 600 foot lamberts, though there is no reason to power up that high; most cockpit designers run them at 200 to 230 foot lamberts, which is the level of an average fluorescent tube, says Atac.

Portable displays lighten up

Portable displays are pushing display technology hard, with their demand for lightweight and low power draw.

Leaders of the U.S. Coast Guard asked Anteon International of Fairfax, Va. to develop a wearable computer for boarding parties to use as they move from government cutters to potentially hostile cargo vessels.

Their job is to inspect and document the cargo and personnel, and then compare that list to a database. Because of the dangerous atmosphere, the computer had to be hands-free, so the Coast Guardsmen could quickly reach their guns. And because of the sunny conditions, most laptops and handhelds would not be visible anyway.

The solution may be a dual-purpose, wireless flat-panel screen called Atigo, made by Xybernaut Corp. of Fairfax, Va. The 8.4-inch, sunlight readable screen is designed for mobile use, with a wireless data connection, and touch-screen and voice-operated commands, says Xybernaut President Steven Newman.

Coast Guard officials insisted on high resolution, since boarding parties must be able to read a full-page manifest on one screen, or see a photo sharply to compare it to shipboard identification cards. Atigo fills this need by offering 800-by-600-pixel SVGA resolution.

Coast Guard planners are testing early copies on some cutters, and the early reactions are good, Newman says.

"In the past, they couldn't bring data and information with them onto the ship, and couldn't do more than spot-check one or two containers, or carry photos of people who were supposed to be on board," he says. "Yet today, they're often called on to compare 2,000 containers with bar codes to the content sheet manifest, to assure it's unaltered. And they check licenses, visas, and permits for the crew."

Tiny LCDs give "X-ray vision"

There is a rumor making the rounds in Baghdad that American soldiers wear sunglasses with X-ray vision powers.

That is not true for the U.S. forces now in Iraq, but DARPA has funded work on a miniature, wireless LCD screen built into eyeglasses. Wearing this display, a soldier can see video taped by a comrade standing in a different room, behind some trees, or in a helicopter hovering above.

Working with researchers at the U.S. Army Soldier Systems Center in Natick, Mass., the DARPA project created this Digital MP (military police) System. Along with wearable computing from Honeywell Inc., it relies on eyeglass-mounted displays from MicroOptical Corp. of Westwood, Mass.

null

The soldiers also could perform facial recognition at guard stations by comparing faces to a database stored in a computer their belts, or a wireless LAN nearby, explains Mark Spitzer, chief executive officer of MicroOptical.

The 1.23-ounce LCD screen offers daylight-visible, color VGA resolution at 640 by 480 pixels. The displays are from Kopin Corp. in Taunton, Mass., then MicroOptical integrates them into eyeglasses.

Future versions could use screens mounted on both sides of the eyeglasses, so a soldier could see images in three dimensions, though with current technology that would boost weight and cost. Spitzer says he also hopes to adopt it for use in homeland security, such as streaming building blueprints to firefighters, or streaming aerial photos to crowd-control police.

The LCD looks like a small screen that hovers in one corner of your view. In a recent demonstration at MicroOptical's offices, a reporter wore the glasses while he pointed a fiber-optic sensor around corners and under tables. The effect was similar to the rear-view mirror on your car's windshield; it doesn't distract you unless you choose to look directly at it, or you glimpse a flash of movement.

MicroOptical has delivered a dozen systems to the U.S. Army for testing in the Digital MP program at Fort Polk, La.

Future technologies get flexible

But the LCD cannot do everything, says the U.S. Display Consortium's Bob Pinnel. Performance requirements for heads-up displays, head-mounted displays, or projection displays demand a different technology solution.

Candidates to fill that niche include future technologies like OLED on silicon from companies like eMagin Corp., of Hopewell Junction, N.Y., and liquid crystal on silicon (LCOS) for applications such as a front (or rear) projection microdisplay, he says.

LCOS will probably reach the commercial market by the fourth quarter of 2003, replacing CRTs in large-screen projection TVs, he says. Shortly after that, contractors could start specifying LCOS displays for military applications such as large-area command-and-control screens, or simulation and training.

While military users dictate the specifications for displays, it is private industry that drives new technologies, Pinnel says. "Then integrators like Honeywell or Rockwell pick them up, ruggedize them, and do the best they can to meet the mil-spec."

That means OLED will have to compete for military applications based on its cost and performance in the commercial market, just as LCD replaced CRT, he says.

The exception to this rule is in military applications that have no commercial equivalent, such as the U.S. Army's Future Combat System, or Objective Force Warrior. The Army Research Laboratory in Adelphi, Md., (ARL) then acts as a stimulator and early adopter of new technologies, to spark supplier companies to create cutting edge displays.

As displays are deployed at the level of the individual soldier, they need to be more rugged, lightweight, and efficient than ever before. So ARL designers are seeking displays on lightweight, flexible plastic instead of glass.

Engineers at the ARL tried to encourage such new technologies last fall when they created the Flexible Display Initiative. Planners there are now working on details of a five-year plan to finish designs for OLED displays in time for the launch of the next stage of the Future Combat System, in 2008-09.

The U.S. Army's Land Warrior program supplies soldiers with networked helmets so they and their commanders will have unprecedented awareness of the battlefield.

Soldiers see that data on a helmet-mounted display that must be small, lightweight, power-efficient, and survivable in warfighting conditions like parachuting and nighttime use.

"It gives soldiers a new capability of situational awareness, and a means of communicating other than waving your arms and shouting," says Jim Melzer, product manager for helmet-mounted displays at Kaiser Electro-Optics.

So Kaiser engineers chose OLED displays, made by eMagin. Prime contractor General Dynamics uses the displays in the current version, LW-SI (Land Warrior, Stryker Interoperable), and the previous version, LW-IC (Land Warrior, Initial Capability).

The SVGA-resolution color displays are COTS equipment, so Kaiser engineers keep costs down but must ruggedize each screen to meet military standards for sand, altitude, temperature, and humidity.

Another challenge is perfect balance of luminance that the display must strike so it is bright enough to use in the dark, yet lets a soldier use his night-vision goggles, and does not give away his position by shining a bright light in his face.

And it must be highly efficient. "To save energy consumption, we're sniffing around for a tenth of a watt here, and a tenth of a watt there," Melzer says. That means the OLED must work in freezing cold weather without drawing extra power.

Finally, the screen has to handle input from sources like weapons sensors and wireless feeds, in addition to the soldier's own wearable computer. In return, soldiers see a dynamic map, with moving icons on it to represent friends, foes, and targets.

In the next step of development, engineers will feed signals from a fused, multi-spectral sensor to the screen, enabling the soldier to see in the infrared range with forward-looking infrared cameras, to let soldiers view the heat in recently used guns or vehicle engines.

Screen development is now in pre-contract, synchronization mode in the wake of the Army's choosing a winner after Phase 1 of the Objective Force Warrior development plan. Army officials picked the General Dynamics Eagle team, but want to integrate that plan with the best technologies from the competing team, the Wolfpack group from Exponent, in Menlo Park, Calif.