By Edward J. Walsh

Today's attack submarine crew must pursue more than enemy submarines; an ever-widening set of responsibilities are pushing submarine designers to upgrade as quickly as possible with COTS, as well as to find innovative new technologies on the commercial market

The U.S. Navy's attack submarine community focused through the Cold War on a single preeminent mission - tracking Soviet attack and ballistic missile submarines closely with an aim to destroy them on a moment's notice should the need arise. Today, Navy attack submariners are starting to see results from their efforts underway since the mid-1990s to adapt to a complex new role.

The modern U.S. attack submarine captain must concern himself not only with tracking enemy submarines and conducting a growing variety of undersea reconnaissance, but he also must configure his resources to support surface battle groups, amphibious forces, and joint task forces. The need to expand the submarine's role centers on an increasingly familiar story - doing more with less.

Those efforts quickly taught submariners and their supporters in industry that they must change dramatically the way they design and build submarines - while slashing costs. The result has been a transformation, led by the use of commercially developed technology, of submarine systems development, manufacturing, systems integration, and production.

Funding remains constrained, yet Navy and industry undersea experts are seeking to boost the warfighting capabilities of the future Virginia-class (SSN-774) attack submarines, of the three interim Seawolf-class (SSN-21) boats not yet in operational service, and of the currently fielded Los Angeles-class (SSN-688) attack submarines.

Systems integrators, instead of developing new combat systems, are inserting commercial-off-the-shelf (COTS) hardware and software to upgrade the older boats. Navy leaders are extending selected elements of those upgrades into the Ohio-class (SSBN-726) Trident ballistic missile submarines.

Upgrade challenges

Submarine program officials say that initiatives to upgrade attack and ballistic missile submarine systems revolve around a particular concern: the Navy risks being left behind as commercial vendors introduce new products often without supporting older technology. The submariners also see COTS as an opportunity to add new capability at reasonable costs. They add that the infusion of COTS now underway will lead by 2004 to a common architecture for submarine combat systems for the attack and ballistic missile submarine fleets.

This illustration depicts the electronic architecture of the future Virginia-class submarine command, control, communications, and intelligence system. This multi-mission attack submarine will have more commercial off-the-shelf electronics content than any other submarine class in the U.S. fleet.

The Navy is shrinking the attack submarine force from more than 80 boats in 1995 to a planned fleet of 50 by 2003.

Top-level discussions on the size of the force continue. A 1998 Joint Chiefs of Staff force-level assessment concluded that the service might actually need 67 to 71 attack boats to carry out the range of new crisis-response missions in support of surface force, Marine Corps, and joint forces.

Ships of all three classes of the attack sub force in coming years must carry out such non-traditional missions as intelligence gathering and surveillance, mine reconnaissance, offensive mine warfare, insertion of special-operations forces, and precision strike. The Virginia class has been designed as a regional, or littoral-warfare platform, designated primarily for those missions. Designers also will outfit it for traditional anti-submarine and anti-surface warfare and precision strike to support land operations.

The sub force, even more than the surface fleet or the Navy's air wings, faced a difficult adjustment to post-Cold War funding realities. For decades submarine designers and builders had been left free to use proprietary systems and components, without much regard for cost, to outfit their ships for the unique mission of the submarine and to meet the demanding safety restrictions needed for a nuclear-powered platform.

Navy leaders pushed forward in the mid 1990s to reshape their next program - then called the new attack submarine, or NSSN - which today has changed to the Virginia class. The Virginia-class initiative, which is the Navy's first acquisition program to incorporate defense-acquisition reform practices, followed a difficult battle to preserve the Cold War-vintage Seawolf program, albeit at only three ships.

Virginia-class submarines

The NSSN initiative, officials say, introduced for the Navy the Defense Department's widely publicized "revolution in business affairs," that encompasses the use of integrated product and process development, a broad shift to COTS hardware and software to replace mil-spec and Navy-unique components, modular construction, and reduction in parts count.

The shift away from tradition started with the shipbuilding contract. To nurture two submarine-building shipyards, General Dynamics Electric Boat in Groton, Conn., and Newport News Shipbuilding in Newport News, Va. will share construction.

Electric Boat will build several hull sections, engine-room modules, and the command and control systems modules, or CCSMs, while Newport News will build the bow, stern, sail, and several forward sections of the hull. Electric Boat will deliver the first and third ships to the Navy, and Newport News will deliver the second and fourth.

The shift to modular construction for the Virginia drives planning for technology insertion. Toward this goal, the ship's combat system architecture is to be based primarily on commercially developed systems. Instead of the traditional approach of building a hull, then hauling equipment through passageways, the CCSM will be outfitted entirely outside the hull. The CCSM will host the ship's command, control, communications, computer, and intelligence (C4I) systems.

Systems integrators from Electric Boat are building the CCSM in their Quonset Point, R.I., facility. They will ship the finished system this summer to the company's Groton, Conn., shipyard. The module is a two-level 60-foot-long platform that weighs some 200 tons.

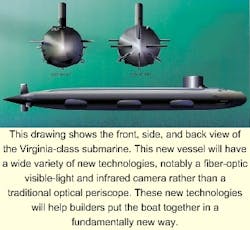

This drawing shows the front, side, and back view of the Virginia-class submarine. This new vessel will have a wide variety of new technologies, notably a fiber-optic visible-light and infrared camera rather than a traditional optical periscope. These new technologies will help builders put the boat together in a fundamentally new way.

It is intended to provide the required hardening for the COTS-based components of the ship's combat systems. It will accommodate the displays, consoles, processors, and peripheral equipment that represents the inboard elements of the ship's 15 C4I systems, packaged in ruggedized standard interface enclosures. Those systems include the ship's radar, sonar, a tactical support system, navigation, electronic support measures, and submarine regional warfare system.

Combat system concepts

Engineers from the Lockheed Martin Undersea Systems division in Baltimore are acting as prime contractor and systems integrator for the CCSM. The company's CCSM contract includes the modules for the second ship of the class, the USS Texas (SSN-775), and options for two additional ships.

Designers from the Raytheon Naval and Maritime Integrated Systems division in Portsmouth, R.I., are providing the combat-control system. Litton Marine Systems in Charlottesville, Va., is building the radar and navigation system. Kollmorgen Electro-Optic in Northampton, Mass., provides the non-penetrating photonic mast.

Electric Boat builds the standard interface enclosures and provides as contractor-furnished equipment the total-ship monitoring system, interior and exterior communications, and the non-tactical data processing system. The systems incorporate 23 subsystems, including the ship's sonar high-frequency chin array, two towed arrays, high-frequency sail array, and wide-aperture arrays. Among the CCSM elements are 22 UYQ-70 display processor consoles, distributed in 70 equipment racks.

The combat-systems contractors this spring will deliver their initial shipsets either to Lockheed Martin's Manassas, Va., site for integration testing or directly to Electric Boat in Groton. Electric Boat engineers will start installing the systems on the module in a CCSM off-hull assembly and test site this November and December.

The CCSM integration effort will tie together the systems builders, the integrator, the shipyard, and the Navy program team. This arrangement is to ensure that development stays on schedule and on budget, says Capt. Terry Haid, assistant program manager for combat systems in the Virginia program office of the Naval Sea Systems Command (NAVSEA) in Arlington, Va.

In January 2001 Electric Boat technicians will carry out power-up and fault-detection testing, followed by the start of integration testing that will run through the end of that year. A 240-hour longevity test is set for January 2002 to validate systems reliability. After that, the systems integrated on the CCSM will go through an early operational assessment in March and April 2002 in preparation for installation of the module in the Virginia hull.

No more periscope

The Virginias will represent the first attack submarine class to field a non-penetrating photonic mast - a multi-sensor system mounted on a periscope mast. Managing the mast program is Capt. David Veatch, manager of NAVSEA's Submarine Sensor Systems program office. Kollmorgen Electro-Optic engineers originally developed the mast under a 1988 contract supervised by the Defense Advanced Research Projects Agency (DARPA) for its Submarine Technologies initiative. Kollmorgen subcontracted the mast portion of the program to Riva Calzoni of Italy, a leading builder of submarine periscope masts. Kollmorgen developed the photonic sensor package.

Veatch says the photonic program switched to the Navy after successful sea trials. Navy officials then funded Kollmorgen to design an improved sensor system. The photonic mast hosts a color TV, monochrome high-definition TV, thermal imager, eyesafe laser rangefinder, electronic support measures sensor, and a communications and global positioning system receiver.

The Virginia program initiated a second program to develop a universal modular mast (UMM) and awarded a development contract to Kollmorgen teamed with Calzoni.

The Virginia-class boats will have eight universal modular masts - two of them with the Kollmorgen photonic-mast sensor packages. Two more universal modular masts will accommodate high-rate data satellite communications antennas, two of which that will act as multi-function communications masts.

The photonic universal modular mast, which the Navy calls "self-contained bearing and mast-erecting system," eliminates the need for a submarine periscope. The UMM will be linked by fiber-optic cable to the CCSM and won't require the internal periscope column. Eliminating the periscpoe column will enable designers to build longer, flatter sailes than those on previous submarine classes, which experts say will improve the vessel's hydrodynamic performance.

Kollmorgen last year purchased Calzoni's mast-building business unit and now operates it as a Kollmorgen division. Kollmorgen engineers plan to deliver the Virginia photonic mast to Electric Boat at Groton by October; in fact they have started work on the photonic mast for for the USS Texas, the second boat of the Virginia class.

Veatch says Navy officials have looked into backfitting the masts for the Los Angeles and Seawolf classes. Designers installed an engineering development model aboard the Los Angeles-class submarine USS Annapolis (SSN-760) for sea trials, which they completed in January. However, no funding is available for a backfitting the mast.

Technology refresh

The Virginia program is facing a tough challenge in keeping technology refreshed. Haid says members of the Navy's program office and the industry team are discussing ways to upgrade the combat systems software and hardware during the roughly 30-month period between the installation of the systems aboard the module and delivery of the ship to the Navy. Submarine systems officials say they are sensitive to the "Moore's law" axiom that computer technology doubles in capability every 18 months.

As a partial solution, leaders of the Virginia program expect to borrow a page from the submarine community's primary acquisition reform initiative, now referred to as the Acoustics-Rapid COTS Insertion (A-RCI) program. The initiative began in 1997 to find COTS breakthroughs in display and processing technology to upgrade the displays, processors, and software that support the acoustic systems aboard the Los Angeles-class boats.

The A-RCI effort began following a program analysis in late 1995, says Capt. Tom O'Connor, manager of NAVSEA's Submarine Combat Systems office. The analysis concluded that ordinarily it would take five to 10 years to upgrade Navy-unique computer hardware and software for the acoustic subsystems aboard the Los Angeles class. "The margin of superiority of our acoustic systems in terms of the threat wasn't what we wanted," O'Connor says. The work focused on the ship's towed arrays, passive hull array, sonar sphere, and the high-frequency active sonar used for under-ice operations and mine surveillance.

The A-RCI analysis found that although the submarines' wet-end sensors were adequate, the ships weren't getting the required performance, he says. "Upgrading the proprietary hardware systems and legacy code would take too long and would cost too much."

The Navy's established technology-development cycle moves from formal program levels: 6.1, basic research; 6.2 technology development, 6.3 advanced development, followed by full-scale development and production. The Navy "had to find a way to break free of that process" for acoustic-systems upgrades, program officials say. Planned upgrades, moreover, covered only the 23 Los Angeles-class improved submarines, the San Juan (SSN-751) through Cheyenne (SSN-773).

The A-RCI effort aimed at shifting the entire submarine acoustic processing and display suite to commercially developed technology within five years. Designers would incorporate the upgrades through phases, starting with the passive towed-array sonars. A second phase would add the hull and spherical arrays, and the third would bring in the high-frequency active sonar.

A-RCI

The first phase of A-RCI upgrades, carried out in late 1997 aboard the attack submarines Augusta and Louisville (SSNs-710 and -724), aimed at enhancing the processor-display suite for the ships' TB-16 and TB-23 towed arrays. Phase 1 replaced one of the four old Navy consoles with a UYQ-70 console fitted with a Hewlett Packard 743 VME single-board computer, an HP J-2240 workstation, and a 17-inch cathode ray tube (CRT) display from the Barco Inc.

Display Systems division in Duluth, Ga. * Designers configured that system, referred to as a control display workstation (CDWS), for the acoustic display role. The prime systems integrator for the Navy's UYQ-70 program is by Lockheed Martin Tactical Defense Systems in Eagan, Minn. The first-phase work also added multipurpose processors (MPPs) from Digital Systems Resources - better known as DSR - of Fairfax, Va., for acoustic processing. The new COTS-based A-RCI processing configuration is designated the BQQ-10.

More ships originally were scheduled to receive the phase 1 upgrade, but O'Connor says the program instead moved directly into phase 2 to replace a second acoustic system display console. Twelve ships, including the two phase-1 attack submarines, were upgraded for phase 2 last year. In May the Navy awarded Lockheed Martin a delivery order for 54 CDWS fitted with additional capability

Al Kochevar, Lockheed Martin's UYQ-70 subsurface program manager, says that the company upgraded the CDWS to an enhanced CDWS (ECDWS) configuration by replacing the HP 743 processor with an HP 744 dual processor - an HP FX-6 graphics engine that provides three-dimensional color. It also will introduce an HP J-5000 workstation to replace the obsolescent J-2240 workstation. The ECDWS, which is for the Los Angeles class and the Trident ballistic missile submarines, also replaces the 17-inch CRT with a Barco 20-inch flat-panel display. The 200 MHz acoustic-processor MPPs are being replaced by 300 MHz processors.

Enhanced combat systems

In late December Navy officials awarded Lockheed a second order for 71 additional ECDWS systems. The company has delivered 14 production ECDWS units and is set to deliver between eight and 12 per month. Those systems are to be installed aboard some 23 more ships this year.

The Lockheed Martin Tactical Defense Systems unit also has delivered two VME-based UYQ-70 shipsets - each with the HP 744 processor - of 21 systems each. These are going to the Virginia-class CCSM prime Lockheed Martin Undersea Systems Manassas, Va., facility for integration with the C4I systems that will go aboard the CCSMs for the Virginia and the Texas.

Kochevar adds that Lockheed Martin-Eagan experts are working with Lockheed Martin engineers in Manassas to upgrade those Q-70 shipsets to the ECDWS configuration with the J-5000 workstation. He adds that eventually the architecture probably will be adapted for either Windows NT or to a new instruction architecture (IA-64), that would support Hewlett Packard, Sun, Windows NT, or other operating systems.

On the software side, A-RCI provides for an annual series of builds, referred to as advanced-process builds (APBs) supported by the Advanced Systems and Technologies Office within the Program Executive Office for Undersea Warfare.

The initial APB replaced the towed-array processing software, while subsequent builds provide upgrades for the sphere, hull, and high-frequency active arrays. O'Connor says the new capabilities that the annual builds provide will flow back through the earlier systems on a continuous basis. "We don't have to wait for quantum leaps over a five-year period," he says.

The A-RCI approach for the Virginias going through construction will give the program the flexibility either to implement new hardware and software, or to defer upgrading the combat system until ship delivery, when the A-RCI "tech insertions" most likely will have progressed to the next generation.

Lockheed Martin and Navy officials say that they are looking at incremental upgrades for the ECDWS to configure it for the Virginia and Seawolf classes - part of a long-term Navy goal of a common combat system for all submarine classes. O'Connor says, "eventually, all the systems will be working off the same displays, operator interfaces, and processors - the only difference will be in the platform-specific sensors." Most of the Los Angeles class have the old CCS Mk 1 combat control system. Raytheon Co. engineers, under contract to the Navy Submarine Combat Systems program office, has developed a CCS Mk 2 in several variants, which has gone aboard several Los Angeles-class ships and aboard the Tridents.

The SSN-improved ships, San Juan through Cheyenne, are equipped with the BSY-1 combat system from Lockheed Martin-Manassas. The Seawolfs have the more capable Lockheed Martin BSY-2. All those systems are built around Navy-unique and proprietary UYK-43 or UYK-7 processor technology running unique software.

The goal, Navy officials say, is to adapt those systems to a UYQ-70 COTS-based architecture that will eventually replace the proprietary hardware and software. The effort will produce a common inboard architecture for the combat systems, although weapons wet-end sensors still will vary to some degree. For example, the Virginia class will be outfitted with a different spherical array than the Los Angeles or Seawolf classes.

The Navy also is looking at forward-fit and backfit enhancements for the wet end of the sensor suite both for the attack and ballistic missile submarines. Navy officials from the Combat Systems program office are expecting delivery by late 2001 of engineering development models of a new low-cost towed-array sonar, designated the TB-29A. This towed-array sonar is targeted for the entire fleet.

New towed arrays

The '29A program replaces an effort to build a new TB-29 towed array that was terminated in the late 1980s when the cost of an individual system reached about $4 million. O'Connor says that the TB-29A goal was to slash the cost of the array by half by incorporating low-cost hydrophones and commercially based telemetry software.

The Navy awarded a contract valued at $31.8 million for the TB-29A development and production to Lockheed Martin Ocean Radar & Sensor Systems (now Naval Electronics & Surveillance Systems) of Syracuse, N.Y., in December 1998. The award was protested by L3 Ocean Systems (formerly Allied Signal) of Sylmar, Calif., and the work on the program was halted. The two companies, both of which have built the TB-16 and TB-23 towed arrays, and the Navy reached an agreement whereby L3, acting as subcontractor to Lockheed Martin, would share development and production work.

Chesapeake Sciences of Millersville, Md., will develop the TB-29A telemetry (the electronic messages that pass acoustic signals from the arrays to the onboard signal processors. The '29A also will be modified as a multi-function towed array (MFTA) for fielding to surface combatants. It is expected to replace the SQR-19 surface ship towed array.

The Lockheed Syracuse unit also is prime for the SQQ-89(v), which in its newest (v)15 variant incorporates, eliminates some 2,600 Navy unique circuit cards. The company also was awarded a contract early this year for production of six BLQ-10 electronic support measures systems, two of which are for the first two Virginia class (SSNs-774 and -775) and the other four for Los Angeles-class boats.

Power architectures

In the domain of submarine power applications, submarine builders, and systems integrators are continuing discussions of conceptual new power architectures based on the introduction of integrated electric drive (IED).

Navy Secretary Richard Danzig announced on January 6 that the Navy's DD-21 land-attack destroyer program would incorporate an IED system for propulsion and ship-systems power. At the same time Danzig predicted that electrical drive also would be extended to submarines to provide the power-management system between the prime mover-the nuclear reactor-and the power loads.

General Dynamics Electric Boat leads an industry team made up of its own Electro Dynamic business unit, Westinghouse's Electro-Mechanical division, Northrop Grumman Marine, SPD Technologies, Eaton Navy Controls, and Ingersoll-Dresser Pump. Newport News Shipbuilding, teamed with Kaman Electromagnetics, which would purchase system components from a wide field of unaffiliated suppliers, also are looking at the electric-drive market, both for the DD-21 and for future subs.

The shape of the future submarine may be determined by its mission package. DARPA and the Navy are managing an 18-month concept definition study of attack submarine payloads and sensors that will be required to carry out the submarine's missions in out in the 2020 timeframe.

Lockheed Martin's "team 2020" includes Northrop Grumman, Electric Boat, Noesis Inc., and nearly 20 other firms, Navy research laboratories, and academic institutions. The Raytheon "Forward Pass" group includes, among others, Electric Boat, Boeing, and BBN.

The study, to end late this year, is according to DARPA supposed to prognosticate about future sub missions-and produce "radical" ideas about weapons, sensors, and command and control systems to help the Navy's future submariners carry out those missions.

null