Wearable computers help make individual soldiers part of the digital battlefield

Wearable computers — devices that are attached or integrated into an individual's clothing — were once considered mostly useful as bulky maintenance devices, but are now considered to be the electronic heart of the soldier of the future. The technology is also helping to improve law-enforcement and anti-terrorism efforts.

By John McHale

Military applications for wearable computers in the past typically included maintenance electronics and medical devices to help experts quickly diagnose equipment malfunctions and soldiers' wounds in the field.

Now, thanks to state-of-art technology and inventive minds in industry and government laboratories, computers are being developed that are wired into clothing and have the capability to track enemy targets, network the soldier with air, land, and sea forces, monitor his physical health, and even translate native languages. Devices are in production that also will aid law enforcement and military personnel in the global war on terrorism.

The wearable computer will offer situational awareness to the infantry soldier that will help separate friend from foe, says Andy Taylor, Objective Force Warrior lead systems engineer at the U.S. Army Soldier Systems Center in Natick, Mass.

Wearable computers will help infantryman use digitally distributed orders, maps, and intelligence. This is no mean feat; these soldiers fight on foot, so their electronic gear must be light, rugged, and easy to use. Wireless technology enables each soldier to communicate seamlessly with his comrades within a networked unit. Eventually Army officials say they would like to give soldiers the capability to exchange video of what they see with each other via miniature cameras interfaced with lightweight wearable computers.

A wearable computer not only is easily accessible on the wearer's clothing, but also has several different inputs, such as a keyboard or biometrics, and has a display in view of the user, says Mike Binko, director of corporate communications for Xybernaut in Fairfax, Va. While wearables are becoming common among utility linemen, telecommunications technicians, aircraft mechanics, and medical personnel, they also are seeing use in law enforcement, counter-terrorism, and military applications, Binko says. Personnel for U.S. Army Smart Sensor Web program at Fort Benning, Ga., are using Xybernaut wearables he says.

The U.S. Department of Defense's Smart Sensor Web program evaluates sensor-fusion technologies that can help improve situational awareness on the battlefield. Xybernaut's wearables took part in exercises at the McKenna Military Operations in Urbanized Terrain (MOUT) test site at Fort Benning, Binko says

The wearables also played a role in a simulated exercise to retrieve hostages, Binko continues. The devices relayed data from unmanned aerial vehicles and from other units to tell the soldiers where the enemy and the hostages were, he explains. The exercise retrieved all hostages, and inflicted only two casualties among the soldiers, Binko says. A similar exercise without Smart Sensor Web resulted in hostage casualties, he adds.

Xybernaut officials won a contract last month to develop wearable computers for maintenance technicians in the U.S. Marine Corps, Air Force, and Navy. Xybernaut's Mobile Assistant V wearable computers will form the foundation of the mobile/wearable platform. Army experts are developing wearable computers for soldiers under two main programs, the Land Warrior in Fort Belvoir, Va., and the Objective Force Warrior out of the Soldier Systems Center. The Army's Land Warrior program is the kickoff point for Objective Force Warrior, Taylor says.

Land WarriorLand Warrior integrates everything the footsoldier wears and carries into a close-combat fighting system that enhances his situational awareness, lethality, and survivability.The Land Warrior's main wearable computer, which uses the Microsoft Windows 2000 operating system on PC/104 printed circuit board hardware, straps to the soldier's lower back. If the owner loses that computer, the soldier can continue using the system's video and thermal weapon sights through a separate communications-navigation (CommNav) unit that runs Windows CE on an Intel Strongarm processor. Version 1.0 is to begin field-testing in the summer of 2002. The software has been designed with soldier testing and input from the beginning, according to the Program Manager (PM) Soldier Systems World Wide Web site at http://www.pmsoldiersystems.army.mil.

Each Land Warrior microcomputer can receive updates with new maps and orders that the user can view on the soldier's monocular helmet-mounted display (HMD). Soldiers also can blend the HMD and Global Positioning System to view where they stand in relation to other squad and platoon members, as well as to known enemy positions. Integrating all of these provides the soldier with unprecedented situational awareness. The computer also provides for future implementation of Combat ID and other emerging technologies.

Through the helmet-mounted display, the soldier can view computer-generated graphical data, digital maps, intelligence information, troop locations, and imagery. The soldier controls menu-driven displays from a touch-control unit on his chest strap, or with two buttons near his trigger finger that enable him to maintain a firing position.

In addition to software applications, the Land Warrior computer offers protection from code viruses, worms, and malicious code, as well as system power management. Software programs control most electronic components and displays. The computer is an open architecture that uses commercial off-the-shelf (COTS) components to enable easy upgrades and system development.

The command-and-control software provides semi-automatic message completion using available system data and employs the Joint Variable Message Format (JVMF) message set for compatibility with the Army's Force XXI digitization effort, PM Soldier Systems officials say. Other software applications provide map and overlay displays, navigation information, fire and obstacle planning assistance and reporting, logistics planning assistance and tracking, checklists and timers, and online technical reference material.

The computer and other electronics resist wear and tear as well as thermal and EMP hazards, but do not have ballistic protection. The casing and rugged material used to stabilize the electronics within it may, however, offer some additional ballistic protection to the soldier.

Not all Land Warriors will be identically equipped. In addition to the standard equipment, squad leaders will have handheld displays with wrist-mounted keyboards. These devices will enable them to create text messages, which they can send by burst transmission via SINCGARS-compatible radio to higher echelons. Additional variants also are being developed for medics, combat engineers, and forward observers.

The Soldier Biological and Chemical Command (SBCCOM) PM-Soldier in Natick, Mass., is the system integration manager for Land Warrior, with the subsystems developed through the collaborative efforts of PM-Soldier Electronics, PM-Soldier Equipment and the Communications-Electronics Command (CECOM) at Fort Monmouth, N.J.

Objective Force WarriorThe Objective Force Warrior program, which seeks to improve on Land Warrior beyond 2010, is to develop wearable computers that will almost be a part of the soldier's skin and not as intrusive as cell phones, Taylor says. The goal is to get them to the point to where an individual does not know it is there.One of the biggest challenges facing engineers working on the program is the way to give it sufficient power without generating excess heat, which might make the soldier a target, Taylor explains. Soldier Systems experts are looking at spreading the heat throughout the uniform and at giving the main power source odd shapes so as not to draw the attention of enemy sensors, he adds.

One of the biggest problems with personal computers is their short battery life, Taylor continues. Engineers at Soldier Systems are looking at technology such as air batteries, which work on air and water, but still have reliability issues and fuel cells, Taylor says. Fuel cells look promising, but have their own set of problems including the stability of the fuel being used such as methanol.

One of the processors Taylor likes for wearable computing applications is the Crusoe processor from Transmeta in Santa Clara, Calif. The devices are small, lightweight, and one of the few heavy-duty processors that do not put large demands on other elements of the system, he explains. It runs at about 800 MHz, he adds.

Future capabilities of wearable computers for the soldier include facial recognition and language translation, Taylor says. Years down the line the goal is to have a device that interprets someone speaking a language such as Hindu or Farsi, then feed it back to the operator in English either through a text format or computerized voice, Taylor explains.

U.S. Army Communications and Electronics Command; U.S. Army Tank and Armament Command Armament Research, Development and Engineering Center; all directorates of the Army Research Laboratory, and the Defense Advanced Research Projects Agency (DARPA) are among the agencies contributing to the program.

Wiring the clothingExperts at Soldier Systems are also exploring ways to weave electric wires and optical fiber optics into textile materials that will yield sophisticated wearable computers without bothersome weight and bulk. Several manufacturing processes are under consideration to mass produce electro-optic textiles, says James G. Fairneny, an electrical engineer and project manager for Manufacturing Processes for Integration of Electro-Optic Conductors and Devices Into Textiles at Natick."The goal is to provide the warfighter with executable functions that require the fewest possible actions on his or her part to initiate a response to a situational combat need by means of intelligent textiles," he says.

Cooperation between Natick Soldier Systems Center's Individual Protection Directorate and the Objective Force Warrior Technology Program Office, Communications and Electronics Command at Fort Monmouth, N.J., and several other military, university, and industry groups are involved with various textile-based projects to make it possible.

Potential solutions include a multi-frequency antenna vest from researchers at the Naval Postgraduate School in Monterrey, Calif., to eliminate the conventional radio antenna troops now carry. The new antenna will provide coverage in the 30-500 MHz and 300-2,000 MHz bands using an ultra-wideband antenna with no visual signature, Soldier Systems officials say.

ConnectionsExisting round connectors for the cabling on the Land Warrior's computer are bulky, costly, and prone to failure because of the fragile pin-and-socket plug, Fairneny says. Exponent in Natick and Thor Electronics Inc. in Salinas, Calif., are working to upgrade the network cables and manufacture a flat, pinless connector with recessed contacts. This connector uses flat pieces of metal in 11, 2.1, and 31 pinless contacts for various cable configurations as a small and flat connector. The setup reduces the cost of existing custom connectors now used by Land Warrior, Soldier Systems officials say.The prototype ultra-low-profile rectangular connector has a plug and receptacle in controlled-force breakaway and quick disconnect configurations, and applies to fabric-based bus or conventional cables. Leaner and lighter, but still rugged, the connector eliminates the expensive pin-and-socket assembly process, Soldier Systems officials say. It meets military requirements for environmental and electrical compatibility, and parts are domestically available in high volume.

Additionally, the American Competitive Institute (a consortium of industry and academia) in Philadelphia will investigate alternative components for flat body conformal connectors and cables. Several commercial-off-the-shelf products are being considered with concept designs to modify the manufacturing process to lower product costs, Soldier Systems officials say. Electrical testing and environmental evaluation is being conducted on modified and all-new products.

Blended fibersOne way of removing external wires and creating a more distributed network of sensors and electronics is to weave the wires right into the fabric, Soldier Systems officials say. Leaders of Photonics Laboratories Inc. in Philadelphia and the Philadelphia School of Textiles have a contract to develop manufacturing processes that blends optical fiber and copper wires into woven and knitted textiles. With these technologies, conductors and optical-electronic systems could be woven into soldier's uniforms during large-scale manufacturing."They're looking at the physical interaction of wires or optics as it goes through machinery," Fairneny says. Textile structures are physically and mechanically different from fiber optics or wires. "Fiber optics that are bent too much will break, while metal wires don't bend back and can get fatigued."

At the Philadelphia School of Textiles, researchers are investigating the mechanical motion of textile fibers, with an aim to modify textiles to accept fiber optics and conductive wires, Soldier Systems officials say. Textiles experts identified mechanical parts that produce sharp bending for potential change, and looked at a variety of fiber optics most able to tolerate bending.

Another way of incorporating electrical networks into soldier clothing is through stitchless-seam technologies, Soldier Systems officials say. The technique entraps fiber optics and conductors either on top of or along the seam of the fabric. Scientists at Clemson Apparel Research at Clemson University in Pendleton, S.C., are investigating combinations of wires to form the electrical characteristics of commercial cables, available connectors, and garment-to-garment and undergarment-to-garment mechanisms.

"One difficulty will be trying to connect the top to the bottom for a complete uniform network," Fairneny says. Clemson experts are considering the specific network necessary for Land Warrior laser sensors on the helmet cover and a general network for the battle dress uniform (BDU) top. The first samples of fabric containing electrical wires and a helmet cover network have been provided.

Fiber keyboardIn a move to eliminate bulky and heavy gear, such as Land Warrior's soldier control unit, WRONZ EuraLab in the United Kingdom won a contract to develop a soft-switch fabric with the required sensitivity to be operational on the sleeve of a BDU and seamless incorporation into the garment."The keyboard would be pressure-sensitive, not touch-sensitive, for use on the battlefield," Fairneny says. "Land Warrior's soldier control unit is a box that sits on the chest. It would be better to integrate that into the clothing for reduced weight."

One goal is to produce a keypad on the sleeve that can interface as the soldier control unit with specific military functions, Soldier Systems officials say. A textile data bus and necessary connectivity to transport the signal from the keyboard to the control electronics is another goal.

Fairneny says a prototype is to provide three or four keys for a few simple commands to prove the concept. Further development should lead to a BDU housing to hold the electronics and a fabric-based display.

PFU Systems Plug-N-Run module sees use in U.S. Special Forces wearable computerEngineers at Tactronics in Westhampton Beach, N.Y., are using a small computer module from PFU Systems in Santa Clara, Calif., for their CROW wearable computer, which they provide for U.S. Special Forces.The CROW — short for computer ruggedized operationally wearable — is a rugged submersible wearable computer, says Bill Silhan, president of Tactronics. Silhan could not comment further on the application due to security concerns.

The CROW uses the PFU Systems NetCard carrier board with Plug-N-Run module with customer-engineered military connectors and enclosure, says Kishan Jainandunsing, vice president of marketing for PFU Systems.

Plug-N-Run modules are ultra-compact system-on-module components, based on the standard PC/AT architecture, which integrates all the functions of a PC motherboard, Jainandunsing says. This reduces the design complexity of embedded systems to PCI bus I/O circuit and software design, and results in fast time to market, and low development cost and risk, company officials claim. The rugged 3-by-5-by-0.7-inch card weighs 6.2 ounces and plugs directly into the company's NetCard carrier board.

The Plug-N-Run module uses a low-power 700 MHz Intel Pentium III microprocessor with 256 kilobytes of L2 cache and an integrated graphics controller. It is for high-performance portable and stationary embedded applications that require a display, PFU Systems officials say.

The CROW system has a monocular goggle with a sunlight-readable, liquid crystal display, Silhan says. The system is a custom design that makes use of commercial-off-the-shelf components, and comes in a man-portable, vehicular, maritime, or airborne computing. CROW has 512 megabytes of RAM, 4 megabytes VRAM, two serial ports, two USB ports, PS/2 keyboard, and mouse as well as an onboard 10/100 Base T Ethernet port. The CROW 2000 also incorporates 2 Type II or 1 Type III PCMCIA slots.

The PCMCIA slots enable flexibility in adding peripheral support such as NTSC video and Firewire (IEEE 1394) input of interfacing to a tactical radio modem such as Viasat's VDC-400, Tactronics officials say. This connectivity enables upload and download via satellite of mission critical data and imagery while in the field, company officials say.

Mass storage is compact flash drives, fixed hard disk drives, or removable PCMCIA drives. In addition to standard rotating media solid-state drives can substitute for increased operating temperature ranges and ruggedization.

CROW exhibits the same ruggedized features include housings machined from solid aluminum billet ensure maximum heat dissipation and permit optimal environmental protection from wet, dusty, and high shock and vibration operating conditions, Tactronics officials say. Each DC powered (9-36 VDC) CROW utilizes MIL SPEC D38999 series connectors ensuring environmental sealing and positive locking, company officials say.

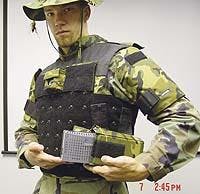

Xybernaut wearable computers aid in homeland securityOfficials at Xybernaut Corp. in Fairfax, Va., are working with Second Chance Body Armor in Central Lakes, Mich., and Viisage Technologies in Littleton, Mass., to create applications for their wearable computers in homeland security and counter-terrorism.Xybernaut's Tactical Wearable Computer will integrate with Second Chance Body Armor for military and law-enforcement applications. This integration is to protect the wearer of the armor and harden the wearable computer for tactical use, Xybernaut officials say.

Domestic applications include nuclear power plants, seaport, airport, and building security. Wearers will be able to see their environment, store information, communicate, record and stream video, operate sensors, and operate geo-spatial position for command and control, all while operating hands free/weapons ready — and be bullet proof, Xybernaut officials say.

Initial units of Xybernaut wearable computers integrated with Second Chance Body Armor have already been shipped to several customers for a major defense contractor's Emergency Tactical Response Vehicle now touring the country, Xybernaut officials say.

Under the agreement with Viisage, Xybernaut experts will combine Viisage's face-recognition electronics with mobile/wearable computers. Configurations include flat panel or head-mounted displays and camera systems for remote surveillance and authorization applications. Viisage and Xybernaut officials plan to offer solutions that require face-recognition surveillance or access verification with mobility and hands-free operation, Xybernaut officials say. Viisage designs biometric face-recognition technology and identification systems and solutions that enhance consumer convenience, improve security, and protect personal privacy, Xybernaut officials say.

Facial recognition in a wearable platform will create new applications for Viisage such as criminal identification, surveillance at sporting events, and someday for military and counter-terrorism operations, says Marc Hodosh, Viisage's director of business development.

The technology is not ready yet for rugged environments, Hodosh says. Current tripod-based applications are more efficient, he continues. Still, the technology will improve and the agreement with Xybernaut is one of the first steps in getting facial recognition technology in a mobile platform, Hodosh explains.

Company informationComputer Sciences Corp.El Segundo, Calif.http://www.csc.comExponentMenlo Park, Calif.http;//www.expo.comGeneral Dynamics Information SystemsMinneapolishttp://www.gd-is.comPFU SystemsSanta Clara, Calif.http://www.pfusystems.comSecond Chance Body ArmorCentral Lakes, Mich.http://www.secondchancebodyarmor.comTactronicsWesthampton Beach, N.Y.http://www.tactronics.comVia ComputersBurnsville, Minn.http://www.viacomputers.comViisage TechnologiesLittleton, Mass.http://www.visage.comXybernaut Corp.Fairfax, Va.http://www.xybernaut.com