High-reliability spring-loaded pin for mating with circuit board pads introduced by Mill-Max

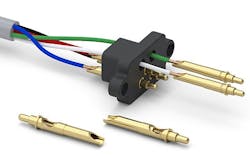

OYSTER BAY, N.Y., 30 June 2016. Mill-Max Manufacturing Co. in Oyster Bay, N.Y., is introducing the 0973-0-15-20-77-14-11-0 high-reliabilityspring-loaded pin for mating with gold-plated printed circuit board pads or Mill-Max target pins and connectors.

The pin offers a solder cup designed to accept wire as large as 20 AWG wire, and has a maximum stroke of .08 inches and can be used at a minimum spacing of 0.1 inches.

The shoulder and barb features are located and designed for assembly into connector housings. The terminating wires may be passed through a connector housing and soldered to the cup of the 0973. Once the soldering is complete the wires can now draw the 0973 spring pins into the housing and the spring pins can be secured with the press-fit.

With the pins securely pressed into the housing, the shoulder acts as a stop, retaining the pins in the event the cable or wires are strained. The shoulder will also prevent push out of the spring pin if the plunger end is over compressed. These design features make the 0973 ideal for cable and bulkhead style connector assemblies.

The 0973 spring pin has a working travel of .04 inches and a maximum mechanical travel of .08 inches. There is a hard stop incorporated to prevent over compression and minimize the risk of damage to the spring.

The high retention force press-fit of the solder cup to the body of the spring pin ensures the reliability of the component during soldering and assembly operations.

Gold-plated brass components and beryllium copper springs ensure conductivity, corrosion resistance, and durability. For more information contact Mill-Max online at www.mill-max.com.

Learn more: search the Aerospace & Defense Buyer's Guide for companies, new products, press releases, and videos