Growth seen in independently developing traditional rad-hard and small sat markets for space electronics

NEW ORLEANS – Demand for radiation-hardened electronics for space applications continues to grow, with opportunities in traditional rad-hard spacecraft, as well as for radiation-tolerant small satellites, industry experts say.

Electronic component suppliers for space applications find themselves serving two distinctly different market segments today, say company officials this week at the IEEE Nuclear and Space Radiation Effects Conference in New Orleans.

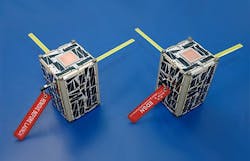

The first rad-hard market segment is the traditional QML-V, in which components are designed from the ground-up for long-term resistance to the effects of the radiation environment of space. The second segment revolves around so-called "small sats" and "cube sats" that can use commercial-grade components. It involves relatively inexpensive satellites expected to last in space for no more than three to five years -- sometimes even less.

The traditional rad-hard market deals in expensive components, made in small numbers, that are expected to operate reliably for years or decades in Earth orbit or in deep space. The small sat market deals largely in commercial off-the-shelf (COTS) parts upscreened for extra reliability that are expected to operate reliably for a matter of months to as long as five years.

"We see a segmentation of the market -- even a new market," says Javier Valle, aerospace systems engineer for high-reliability products at Texas Instruments Inc. in Dallas. "It's not fair to compare these market segments because of scale. We are talking thousands of parts vs. hundreds of parts."

Both market segments today are growing -- the traditional market is in a cyclic upswing, while the small sat market is increasing due to sharply reducing launch costs from commercial space companies, and from a growing demand for small sats for applications ranging from Earth observation to space-based communications and networking.

"Small sats is an exciting area; they're still in space, so there are radiation effects that designers need to be concerned with," says Andrew Popp, space products marketing manager at International Rectifier HiRel Products Inc., an Infineon Technologies company in El Segundo, Calif.

Some small sat applications are expected to operate reliably for relatively short durations and are little concerned with long-term reliability. Still, those serving this market are starting to think about pushing the limits of reliability using upscreened COTS parts and subsystems designed for radiation environments.

One approach to this involves using at least one traditionally radiation-hardened chip among many COTS components, which designed for long-term space radiation, which can monitor the performance of other on-board components and subsystems.

"Small sats and the constellations are growth areas," says International Rectifier's Popp. "The traditional market is constant; it is cyclical but stable." He also points out potential growth in the traditional rad-hard market from India, Russia, China, and "anyone building satellites."

It's unlikely that the traditional rad-hard space market will slow significantly in the long term, says Josh Broline, strategic marketing manager for mil/aero products at Intersil Corp., a Renesas company in Palm Bay, Fla.

"In the high-rel traditional market the growth is good; there's still a lot of interest in rad-hard," Broline says. Still, he says the small sat market "is all very interesting. Low cost is required, but there is volume to back it up."

Related: Radiation-hardened space electronics enter the multi-core era

Spacecraft designers are getting smarter about using COTS components and rad-hard designs for small sats, such that they likely will continue pushing the limits of reliability with a mix of traditional and small sat design approaches.

"People are becoming more comfortable with how to produce and use the small sats," says Anthony Wilson, applications and radiation assurance engineer at Cobham Semiconductor Solutions in Colorado Springs, Colo.

"Processing power has gotten a lot better. Imaging is getting a lot better." He speculates that years down the road the small sat designers may be able to take over some of the spacecraft tasks handled today by traditional rad-hard designs, but for now "I don't see them taking over a lot of the traditional satellites."

Learn more: search the Aerospace & Defense Buyer's Guide for companies, new products, press releases, and videos