Secure high-density digital memory for military and aerospace uses introduced by Mercury

ANDOVER, Mass. – Mercury Systems Inc. in Andover, Mass, is introducing a high-densitysecure memory product line that integrates double-data-rate fourth-generation synchronous dynamic random-access memory (DDR4 SDRAM) with -SWaP-efficient packaging technology.

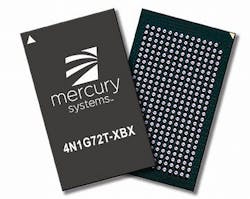

Replacing as many as 18 industrial or commercial DDR4 devices with one military-hardened component, Mercury delivers 75 percent space savings in a ball grid array (BGA) package with data transfer speeds as high as 3200 megabits per second.

Mercury's Advanced Microelectronics Center (AMC) in Phoenix will produce 8-gigabyte DDR4 devices later this year, 2- and 16-gigabyte devices after that.

Mercury's 3-D packaging technology transforms a two-dimensional array of discrete memory devices into one vertically stacked dense BGA package without sacrificing the benefits of DDR4 adoption, company officials say.

Related: Rackmount secure server for cyber security and system integrity introduced by Mercury

Mercury uses thermal and electrical modeling to select and integrate components to enable the devices to withstand harsh operating environments. Lead alloy solder enhances reliability of the mechanical and electrical interface.

Mercury builds all high-density secure memory products at the company's Defense Microelectronics Activity (DMEA)-trusted facility in Phoenix.

For more information contact Mercury Systems online at www.mrcy.com/DDR4.

Learn more: search the Aerospace & Defense Buyer's Guide for companies, new products, press releases, and videos