DARPA to push bounds of additive manufacturing by using 3D printing to fabricate complex integrated circuits

ARLINGTON, Va. – U.S. military researchers are asking industry to use 3D printing and new materials to fabricate complex integrated circuits for future aerospace and defense systems.

Officials of the U.S. Defense Advanced Research Projects Agency (DARPA) in Arlington, Va., have issued a program solicitation (DARPA-PS-24-06) for the Additive Manufacturing of MicrosystEms (AMME) program.

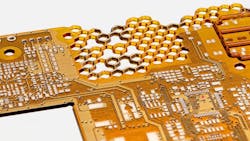

The goal is to invent radically new approaches to additively manufacture three-dimensional (3D) non-planar microsystems. The program will develop materials and a new 3D printing technology able to print several materials simultaneously with fine features at high speeds.

The aim is to demonstrate a functional microsystem that uses the AMME technology to create the mechanical structure and interface between individual microsystem components.

Related: New frontiers in 3D printing

3D printing, or additive manufacturing, is the construction of a 3D object from a computer-aided design model or a digital 3D model in which material is deposited, joined, or solidified under computer control, with the material being added together layer by layer.

3D printing has shattered the boundaries of traditional manufacturing by enabling the production of complex geometries that previously were impossible to produce, DARPA researchers say. 3D printing also has become the preferred manufacturing technology for rapid prototyping of plastics, metals, and composite structures.

Still, 3D printing is not used in electronics or microsystem manufacturing because of limitations in material quality, high-resolution, and high-print throughput.

Microsystems seamlessly integrate mechanical, electrical, and bio-sensing subcomponents. Today's microsystem 3D printing uses either extrusion or photoreaction-based techniques, which are limited in material quality, resolution, and throughputs necessary to print high-performance microsystems.

Related: Navy weapons researchers ask for industry’s ideas in advanced MMIC ASICs and circuit boards

Photoreaction-based approaches can print polymer material at high- resolution by using voxel-by-voxel printing like two-photon polymerization, but is limited to low throughput. Layer-based techniques like projection micro-stereo lithography and volumetric printing like computed axial lithography have demonstrated higher throughputs by photoreactive methods, but still print one material at a time and are limited to large resolutions.

Today no 3D printing method exists that can print several high-quality materials at high-resolutions and high-throughputs to make microsystem 3D printing a viable technology.

The AMME program seeks to change all that by allowing for simultaneous printing of distinct materials within a microsystem. If successful, AMME will enable designers to conceive of new microsystems that previously were impossible to fabricate. Possibilities include enhancing commercial devices with military add-on technologies for quick-reaction missions or fabricating reconfigurable smart surfaces.

AMME seeks to use additive manufacturing to manufacture 3D non-planar microsystems with a voxel resolution of 0.125 cubic microns at throughputs of 1010 cubic microns per second. The goal is to demonstrate a functional microsystem using 3D printing that achieves the synthesis of high-quality conductors and insulators at resolutions and throughputs that are not possible today.

Related: Contract manufacturing: there when you need it

AMME will focus on commercializing this technology quickly to produce a manufacturing system that the U.S. military can adopt quickly to manufacture differentiated technology like military enhancements to commercial-off-the-shelf (COTS) technology.

Companies interested should submit 5-page abstracts no later than 9 April 2024 to the DARPA BAA website at https://baa.darpa.mil. Upload full proposals to the DARPA BAA website no later than 23 May 2024 at https://baa.darpa.mil.

Email questions or concerns no later than 7 May 2024 to [email protected]. More information is online at https://sam.gov/opp/099dbf45e4134978902db9020b1fdeb1/view.

John Keller | Editor-in-Chief

John Keller is the Editor-in-Chief, Military & Aerospace Electronics Magazine--provides extensive coverage and analysis of enabling electronics and optoelectronic technologies in military, space and commercial aviation applications. John has been a member of the Military & Aerospace Electronics staff since 1989 and chief editor since 1995.