Honeywell to continue sustaining radiation-hardened circuit manufacturing capability for space applications

CRANE, Ind. – U.S. military researchers are boosting the defense industry's ability to integrate radiation-hardened microelectronics components for space applications, as well as those expected to operate through nuclear events like atomic explosions.

Officials of the U.S. Naval Surface Warfare Center in Crane, Ind., announced a $25.8 million order Monday to Honeywell International Inc. in Minneapolis to help sustain the nation's strategic radiation-hardened microelectronics facility and production capability.

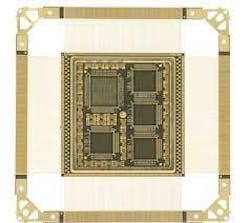

The Honeywell Aerospace segment operates two advanced radiation-hardened microelectronics manufacturing facilities -- one in Plymouth, Minn., and the other in Clearwater, Fla. These are among the few remaining U.S. facilities for weapons-grade rad-hard integrated circuit manufacturing able to withstand radiation doses that exceed 1 megarad.

Related: The quest for commercial-performance electronics in space

This order asks Honeywell to sustain the company's strategic radiation-hardened microelectronics capability through researching extensions of existing products and technology, radiation testing and analysis, and sustaining existing application specific integrated circuit (ASIC) product support and multi-project wafer test and modeling capability.

The services are necessary to maintain a domestic trusted source for strategic radiation-hardened microelectronics to meet the U.S. Department of Defense (DOD) certification to Congress, as stipulated by the fiscal 2018 National Defense Authorization Act Section 1670, DOD officials say.

Radiation-hardened microelectronics components are necessary for manned and unmanned spacecraft operating on long-duration orbital missions in high-radiation space environments like geosynchronous orbits.

Related: Radiation-hardened electronics keep orbital satellites functioning

Rad-hard components also are necessary for mission-critical military applications like ships, aircraft, and land vehicles that would be expected to operate through the effects of nuclear explosions.

Although there are several microelectronics designers able to produce components appropriate for some spacecraft, few companies remain that are able to produce components able to withstand long-duration exposure to intense radiation, or exposure to weapons-grade radiation.

On this order Honeywell will do the work in Plymouth and Minneapolis, Minn., and should be finished by December 2027. For more information contact Honeywell online at https://aerospace.honeywell.com/us/en/products-and-services/product/hardware-and-systems/microelectronics, or the Naval Surface Warfare Center-Crane at https://www.navsea.navy.mil/Home/Warfare-Centers/NSWC-Crane/.

About the Author

John Keller

Editor-in-Chief

John Keller is the Editor-in-Chief, Military & Aerospace Electronics Magazine--provides extensive coverage and analysis of enabling electronics and optoelectronic technologies in military, space and commercial aviation applications. John has been a member of the Military & Aerospace Electronics staff since 1989 and chief editor since 1995.