In some ways reminiscent of Star Trek’s replicators, 3D printers seem to create something out of nothing, shaping a powdered construction material into whatever object the user needs. The possible applications keep growing as new materials, beyond plastics, become available for ever-larger 3D printers.

Although the technology is still in its early stages of development as something beyond its early years as a curiosity, it already is being used in aerospace and defense, primarily for prototyping under the term “additive manufacturing,” but also for the temporary replacement of non-critical parts as 3D printing. According to GE Additive in Auburn, Ga., those are two of the pioneering sectors for additive manufacturing.

“These sectors are characterized by small batch sizes and manufacturer-specific adaptations. At the same time, these products are renowned for having very longlife cycles, and extremely high safety requirements. High levels of thermal or mechanical loading, especially during take-off and landing or if there is air turbulence, are one of the special features of the requirements profiles for most components,” according to the company.

When it comes to product longevity, 3D printed components may be used in passenger aircraft for more than 30 years.

In December 2019 the U.S. Air Force, within its Materiel Command’s Rapid Sustainment Office at Wright-Patterson Air Force Base, Ohio, set up the first program office for agile manufacturing. The goal was to think about the strategy and overall adaptation of agile manufacturing throughout the Air Force; what are the manufacturing materials, processes and technologies needed and how to deploy that across the service.

“The real need for us is 50 percent of the Air Force supply chain is provided by a single source or no source at all, so we’re looking at additive manufacturing as a way to provide a new source,” says Nathan Parker, Deputy Program Executive Officer in the Rapid Sustainment Office. “There are a lot of nodes in the value stream — from reverse engineering to material and machine quality to production and support, all of which we are involved in, to one extent or another.”

Use of 3D printed parts is growing, Parker points out. “Looking at how we are doing, two to three years ago there were around 100 printed parts, today there are almost 2,000. Obviously, we want to continue to grow that and apply what we have learned across the enterprise.”

Design challenges

Between metal and polymer, the Air Force has more than 130 machines, all in major fixed facilities in the U.S. The service has special needs, however. Some Air Force 3D printing needs only now are beginning to be addressed, some of which remain outside of today’s most advanced technologies.

“The state-of-the-art for us is a bit of a challenge,” says the Air Force’s Parker. “Everything we do requires an air worthiness certificate, so we have to have a level of confidence that the part we print is the part we wanted. So for us, state-of-the-art is really about thinking how you deploy an enterprise solution across multiple platforms so multiple users can tap into and use that.”

For the Air Force, production capability is the key. “It’s helpful to think of these as individual nodes that have to grow in unison from a technology perspective,” Parker says. “I can have a large quantity of qualified materials to print parts, but if I don’t have production capacity, it won’t really move the needle. So we’re looking at what machines are needed and where and what materials are available to pull all that together. We’ve had a great improvement over a short period of time, but how do we continue to grow it? We need testing to ensure these parts are safe to fly. There are a lot of things in the overall process we have to work through — it’s not just a matter of materials and machines.”

The U.S. Defense Advanced Research Projects Agency (DARPA) in Arlington, Va., also is heavily involved in advancing and improving 3D printing.

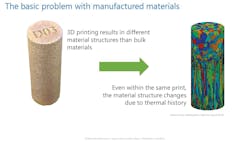

“Open Manufacturing was a very elaborate program — how do you get first time quality when you print something. The big problem with printing now is the materials properties are quite different from what you find in bulk material and they change during the build of the part, primarily due to the thermal history,” says Jan Vandenbrande, program manager in the DARPA Defense Sciences Office (DSO).

“The consequence is your final parts will have different properties through the entire build, so how do you satisfy the original requirements of structural integrity; how much energy should you deposit; how fast should we traverse; how much material should you lay down? We put together a computational system to tell how to set the machine to get first-end quality,” Vandenbrande explains. “That means now we have shown you can actually use computational tools to figure out how to do something without having to do it many, many times to get a quality build.”

Vandenbrande was DARPA’s program manager for the now-completed Open Manufacturing program and heads the agency’s Transformative Design (TRADES) program.

“3D printing allows some control over material properties at pretty much every point and the creation of very fine micro structures,” Vandenbrande says. “If configured properly, you can create capabilities that don’t exist in nature; you can create a structure with built-in resonators. The problem is trying to design something of this complexity is beyond what current CAD/CAM can handle. TRADES is trying to come up different ways of representing shape, compute strength and how to meet design objectives.”

State of the art

The state-of-the art in 3D printing enables the creation of components for a wide range of applications that cannot be made with other manufacturing methods. An example is the General Dynamics leak fuel nozzle. They created a printed fuel nozzle as a monolithic part, which eliminated all the internal brazing that was causing failures. The result was an intricate fuel nozzle with a lot of internal structures to mix air and fuel that no conventional manufacturing method can accomplish.

However, it is still very hard to control material properties and defects that may appear. Another problem is the accuracy is still not quite as good as desired.TRADES is investigating different ways of controlling the machines to ensure what is deposited is really what is wanted.

“It’s a rapidly changing field with a lot of innovation happening. Several of our sites have 3D printers for plastic prototypes and we’ve started using other materials, such as metals. On the metal side, there is a lot of effort going on, especially by platform manufacturers, who have the resources to tune their processes and do materials research,” says Ivan Straznicky, Chief Technology Officer for Advanced Packaging at the Curtiss-Wright Corp. Defense Solutions division in Ashburn, Va.

“The main metal formation methods include direct metal laser centering, which is a subset of powder bed fusion, and directed energy deposition, which is not quite as developed. One of the main materials is aluminum silicon magnesium, which has good properties for being made into powder and laser meltability.”

Curtiss-Wright is using 3D prototyping for fit checks. As for actual parts, that is still in the R&D stage, mostly on the research side. Even so, Straznicky agrees with Vandenbrande that, while not a high volume manufacturing process, 3D printing can create parts impossible with traditional manufacturing processes. That, he says, is one of the real advantages of metal 3D printing. Still, he admits, “not everything has worked as planned.”

Some companies are using 3D printing for operational parts, however.

“We do additive manufacturing, using Ultem 9085, a high temperature, high strength thermal plastic, to build the air distribution system for our next generation inertial navigation, which is called WSN-12, for the Navy, replacing the WSN-7,” Tom Disy, Manager for Strategy and Business Development at Northrop Grumman’s Maritime Systems & Integration unit, says.

“Within the system is a requirement to have fairly small and elaborate ducting for air to cool the system, a geometrically complex component where additivemanufacturing is really useful,” Disy says. “At first we were going to attempt that using sheet metal, but that would have involved a lot of welding. By using additive manufacturing instead, we have reduced the number of quality assurance inspections, reduced cost and improved on the performance.”

Northrop Grumman also uses polymer based materials, such as nylon or plastics, to create custom tools or fixtures to improve the manufacturing process, and designing and printing needed tools rather than trying to use something not really designed for the task.

“It’s easier to produce the printed component than to design, train and manufacture using traditional methods. However, 3D printed materials sometimes are not suited to stress or heat levels required for DoD applications, so it is not a panacea,” Disy acknowledges. “It has a niche — and the one we have found is geometrically complex components. I think technology will naturally move toward better materials that will increase applications for DoD components. There are metallic additive manufacturing capabilities that someday could be of use, for example.

“The fact you don’t have to retool and repurpose your line means you can just write new software, making it easier to keep up with advances in the technology,” Disy continues. “Those are moving quickly and the workforce has to pay attention to make sure they are considering the latest technologies available.”

Limitations on 3D printing

Technically and theoretically, with additive manufacturing, “anything can be printed” — across size scales from nano-scale to printing a building, and across a full gamut of material types: metals, polymers, biologic tissues, composites, concrete, etc. It also is a global technology, with advancements of the state-of-the-art rapidly occurring internationally. Europe, Asia, Australia, the U.S. — all are aggressively doing R&D in additive manufacturing.

But there are limitations, Curtiss-Wright’s Straznicky warns.

“Very small is beyond the capability of the direct metal laser centering process. Melting those little beads creates a relatively rough surface that needs machining or shock/laser peening. So the potential there is limited,” he says.

“The economics are such it is not a high-volume process. There are only so many pieces you can create in a build effort compared to a traditional production process. In terms of cost, it won’t necessarily create the lowest cost production piece. But if you are spending a lot of money to build and assemble a complicated piece, you might save money on those, depending on the size of the piece.”

Size, weight and power consumption (SWaP) is practically a requirement in virtually all military programs today. But for the Air Force, it is superseded bynecessity.

“It’s a secondary factor. Size and weight we factor in on whether we can print it on the machines we have today. But the primary focus for us is a diminishing manufacturing issue, single source issue, long lead time on a part. One of our platform partners has parts that fit between the fuselage and the wing and it is a challenge to find replacement parts on those wedges, which, with age, can come lose in flight,” Parker says.

“Through traditional manufacturing, because this material is hard to source, it can take up to 16 weeks. We had a plane land on a Thursday, the specs were sent to 3D printing over the weekend and the plane was back in the air within two weeks. There is a lot of discovery happening with respect to additive manufacturing as it is being used in the Air Force.”

Northrop Grumman’s Disy says there are a lot of advantages to using 3D printing, but also some disadvantages in aerospace and defense applications.

Complex requirements

“One advantage would be adapting to geometrically complex requirements. Something that traditionally requires a lot of metal bends and multiple components connected now can be one continuous piece,” Disy notes. “Another benefit is speed-to-solution. With traditional manufacturing, you need drawings and templates and much more extensive efforts. You can do that much faster with 3D printing. Suitable materials is probably the biggest barrier in terms of strength and heat.”

Although a lot of development remains to be done in many areas, Curtiss-Wright’s Straznicky notes additive manufacturing is not just for structural parts.

“3D printing also has a lot of work going on in ink jet materials to create circuit boards in an additive way rather than subtractive. Some of the circuits created are pretty remarkable,” he says. “From an OEM perspective, you eventually buy one of the printers and create a circuit overnight rather than waiting weeks or perhaps months for a board from a traditional manufacturer using a subtractive process. So the flexibility elements from an OEM perspective are pretty high. You can print a circuit board overnight and start working on a new component the next day.

“The plastic processes are quite mature, so not much more change there [in the next few years] and metal processes will be creating more and more productionparts. 3D buildup is still a question. Some people are talking about actually printing components, but that won’t happen in the next five years — it could be 20 to 50 years away. That is the area where I see the most change and growth, the printing of circuits using the ink jet process, which is a multimaterial printing system. That area is growing pretty quickly and has a lot of potential.”

3D printing of metals and polymers is inexpensive compared to subtractive methods in low volumes; in higher volumes, legacy subtractive methods like injection molding and casting generally are still cheaper than 3D printing. However, as the industrial base for printing for heavy industries — such as aerospace and defense — ramps up, those costs will come down, as much of the cost is the input raw material, post-print processing and quality control.

While the Air Force has high hopes and expectations for 3D printing in the next five years, Parker acknowledges a lot still needs to be accomplished.

On-demand printing

“There are three categories we’re looking at where we need to drive Air Force work,” he says.

1 — “On demand printing capability. That’s a major focus of the effort, moving from being used in a prototype phase to actual parts. That will help inform what machines we buy and where we use them.

2 — “Large scale parts. A lot of the machines are smaller than what we need for a lot of the parts on our aircraft. It’s been really successful in printing small case parts, but we need to move to larger parts. We’re working on a massive area manufacturing system, designed to get us to larger parts. We’re working with AFRL and America Makes, which is a large DoD consortium that handles additive manufacturing across a lot of different industry areas.

3 — “Cyber security. Having networked printers through some kind of connective network, there is a unique cyber threat associated with that. There are potentially some hard to detect flaws that could affect 3D parts, so it is essential we secure that network and have a really good, robust solution to mitigate those vulnerabilities. We’re in the early stages of designing cyber security in from the beginning on our networks.”

“We’ve reached the 80 percent mark, where in many instances the promise is becoming reality, but the 20 percent for some applications will take a lot more work,” he says. “Things like porosity is a problem. If you don’t entirely melt the tiny beads, you’re creating a porous material that will not have uniform properties. If those pores are close to the surface, you can create crack nitiation sites, which can be a real problem with things such as aircraft wings.

“Before the use of metal 3D printing becomes really widespread, those problems need to be solved,” Straznicky continues. “We’re working on approaches to shock peening — basically bombarding the surface with really hard metals that make it much harder to create a crack — and laser peening.”

Industry experts agree 3D printing has changed the limits of design innovation. The potential for new designs is significantly higher than for traditional manufacturing. Metal printing enables the creation of shapes traditional metal fabrication processes cannot match. Even existing parts that require the joining of disparate pieces potentially can be made in a single shot with 3D printing.

Still a new concept

Despite many successful applications of 3D printing, primarily in prototyping but increasingly in fieldable parts, it is still a relatively new concept that must overcome both its own current limitations and the doubts and questions of potential users. Vandenbrande says that is what DARPA hopes to accomplish with its TRADES program.

“New manufacturing technologies such as additive manufacturing have vastly improved the ability to create shapes and material properties previously thought impossible. Generating new designs that fully exploit these properties, however, has proven extremely challenging. Conventional design technologies, representations and algorithms are inherently constrained by outdated presumptions about material properties and manufacturing methods. As a result, today’s design technologies are simply not able to bring to fruition the enormous level of physical detail and complexity made possible with cutting-edge manufacturing capabilities and materials,” according to the TRADES entry on DARPA’s website.

“DARPA’s Transformative Design (TRADES) program aims to advance the foundational mathematics and computational tools required to generate and better manage the enormous complexity of design. TRADES intends to develop engineering tools to address design representation, analysis and synthesis. The final TRADES technologies should allow designers to more easily navigate the design space to discover non-intuitive — yet realizable — designs that fully leverage new materials and advanced manufacturing approaches, ultimately showing a way forward for future design systems and processes.”