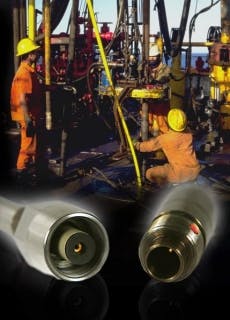

Rugged connector for metal-clad cables in harsh-environment applications introduced by ITT

Feb. 16, 2011

SANTA ANA, Calif., 16 Feb. 2011. ITT Interconnect Solutions in Santa Ana, Calif., is introducing a permanent downhole gauge rugged connector for applications in hazardous-environment applications like oil and gas exploration and production projects.Designed to operate at the maximum limits of metal clad cables, the permanent downhole gauge connector can withstand pressure as strong as 10,000 pounds per square inch and operating temperatures as hot as 200 degrees Celsius in harsh-environment applications such as drilling and mining.Protecting expensive gauges and important data from damage arising from failure of metal clad cable sheathing, ITT's scalable permanent downhole gauge connector features a replaceable metal-to-metal, connector-to-cable seal that is field-attachable and verifiable on-site before operational deployment into a well. The advanced design also includes an elastomer back-up seal. The connectors are re-usable.

Applications include deep-set gauges to monitor ESP intake and discharge pressures in order to maintain optimum ESP efficiency; deep-set gauges to detect water, steam or CO2 breakthrough and deep-set gauges to monitor the effect of hydraulic fracturing in real time.

For more information contact ITT Interconnect online at www.ittcannon.com.

Voice your opinion!

Voice your opinion!