By John McHale

MADRID, Spain - Boeing researchers and industry partners throughout Europe plan to flight test a piloted airplane this year powered only by a fuel cell and lightweight batteries in an effort to develop clean technologies for aerospace applications.

The systems-integration phase of the Fuel Cell Demonstrator Airplane research project, under way since 2003 at Boeing Research and Technology-Europe (BR&TE) in Madrid, Spain, is complete. Systems integration testing is in progress in preparation for upcoming ground and flight testing.

“Given the efficiency and environmental benefits of emerging fuel cell technology, Boeing wants to be on the forefront of developing and applying it to aerospace products,” says Francisco Escarti, BR&TE managing director. “The Fuel Cell Demonstrator Airplane project is an important step in that direction.”

A fuel cell is an electrochemical device that converts hydrogen directly into electricity and heat without combustion. Fuel cells are emission-free and quieter than hydrocarbon fuel-powered engines. They save fuel and are cleaner for the environment.

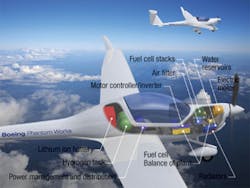

The Boeing demonstrator uses a Proton Exchange Membrane (PEM) fuel- cell/lithium-ion battery hybrid system to power an electric motor, which is coupled to a conventional propeller. The fuel cell provides all power for the cruise phase of flight. During takeoff and climb, the flight segment that requires the most power, the system draws on lightweight lithium-ion batteries.

The Boeing Fuel Cell Demonstrator Airplane uses a Proton Exchange Membrane (PEM) fuel-cell/lithium-ion battery hybrid system to power an electric motor, which is coupled to a conventional propeller.

Flight tests, which will take place in Spain, will demonstrate for the first time that a manned airplane can maintain a straight level flight with fuel cells as the only power source.

“While Boeing does not envision that fuel cells will provide primary power for future commercial passenger airplanes, demonstrations like this help pave the way for potentially using this technology in small manned and unmanned air vehicles,” Escarti says. “It also gives us hands-on experience to complement other fuel-cell studies being carried out throughout the company.”

Boeing researchers see promise in other types of fuel-cell technology, as well as the PEM system. An example is a Solid Oxide Fuel Cell that could be applied to secondary power-generating systems, such as auxiliary power units. This technology could be mature enough in 10 to 15 years for potential use in commercial aviation, Boeing officials say.

The PEM fuel-cell system used on the flight demonstrator was designed and built by the United Kingdom-based company Intelligent Energy.

The demonstrator aircraft is a Dimona motor glider, built by Diamond Aircraft Industries of Austria, which also performed major structural modifications to the aircraft. With a wingspan of 53.5 feet, the airplane will be able to cruise at approximately 62 miles per hour using fuel-cell power.

The Madrid-based avionics group Aerlyper performed airframe modifications, as well as the mounting and wiring of all components; SAFT France designed and assembled the auxiliary batteries and the backup battery; Air Liquide Spain performed the detailed design and assembly of the onboard fuel system and the refueling station; the Electronic Engineering Division of the Polytechnic University of Madrid (School of Industrial Engineering) collaborated in the design and construction of the power management and distribution box; post-integration bench testing is being conducted in a facility that belongs to the Polytechnic University of Madrid (INSIA); and SENASA (Spain) will provide a test pilot and facilities for flight tests.

Other suppliers for the Fuel Cell Demonstrator Airplane include UQM Technologies Inc. (United States), MT Propeller (Germany), Tecnicas Aeronauticas de Madrid (Spain), Ingenieria de Instrumentacion y Control (Spain), GORE (Germany), Indra (Spain), and Inventia (Spain).