Army surveys industry for companies able to provide Nd: YAG laser for etching and semiconductors manufacture

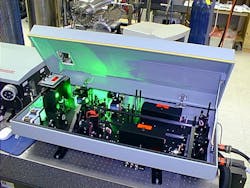

ADELPHI, Md. – U.S. Army researchers are surveying industry for companies able to provide a pulsed neodymium yttrium aluminum garnet (Nd: YAG) laser for cutting and welding steel, semiconductors, and various alloys.

Officials of the Army Contracting Command-Aberdeen Proving Ground in Adelphi, Md., issued a sources-sought notice (W911QX-24-Q-0102) on Thursday for the Nd: YAG laser project. The Army wants quick-turnaround responses by this week.

Nd:YAG lasers are used in manufacturing for engraving, etching, or marking a variety of metals and plastics, or for metal surface enhancement processes like laser peening.

Related: Chasing the goal of an efficient battlefield laser

Researchers specifically are interested in an Nd: YAG laser with:

-- at least eight 825 millijoules of energy per laser pulse;

-- laser pulse width between five to 15 nanoseconds;

-- laser wavelength of 1,064 nanometers;

-- pulse repetition rate of 10 Hz;

-- beam diameter between seven to 12 millimeters;

-- beam divergence less than 0.5 milliradians;

-- a pulse-to-pulse energy stability of 2 percent;

-- power supply with 100 to 240 volts AC at 50/60 Hz, single phase, and 1100 volt-amperes;

-- a cooling unit with an air to water heat exchanger that operates between 18 to 28 degrees Celsius;

-- air to water heat exchanger; and

-- quick installation kit.

Related: Laser weapons: moving from promise to performance

Companies interested should email responses no later than Friday 12 April 2024 to the Army's Andrew Merdoc at [email protected].

Email questions or concerns to Andrew Merdoc at [email protected]. More information is online at https://sam.gov/opp/642b6d01d34e4139bef3f06ddd1a1a2f/view.

About the Author

John Keller

Editor-in-Chief

John Keller is the Editor-in-Chief, Military & Aerospace Electronics Magazine--provides extensive coverage and analysis of enabling electronics and optoelectronic technologies in military, space and commercial aviation applications. John has been a member of the Military & Aerospace Electronics staff since 1989 and chief editor since 1995.