Army selects Ateios for safe, semi-solid-state batteries offering energy resilience on the battlefield

NEWBERRY, Ind. – The U.S. Army Contracting Command in Adelphi, Md., has awarded a one-year sole-source contract to Ateios Systems in Newberry, Ind., to produce three-amp-hour lithium-ion batteries with the ability for reduced fire risk from battlefield damage.

These batteries will feature the Ateios electrolyte and electrodes, designed to integrate with existing military battery packs. The preliminary design combines a graphite-based anode with a semi-solid-state NMC cathode to enhance safety and performance.

Ateios has developed a manufacturing process for lithium-ion batteries using energy-curable composites, which remove toxic solvents and expensive natural gas-powered ovens to produce the most critical battery component: the electrode.

"This contract, along with our strong partnership with DOD stakeholders, will help build a solution that untethers the military from fuel dependency," says Rajan Kumar, CEO of Ateios Systems. "We are using a cost-effective model built around a domestic supply chain, ensuring scalability across all military branches."

The company is shipping production-grade components that integrate into existing battery manufacturing supply chains. In 2022, Ateios and the Army Research Laboratory in Adelphi, Md., collaborated on a semi-solid-state electrolyte using energy-curable polymers.

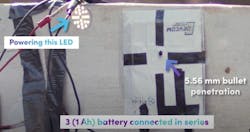

Ateios demonstrated Ah-sized batteries that remained operational even after being pierced by .50 caliber bullet. A video demonstration of the bullet hitting the battery is online at https://www.youtube.com/watch?v=RJV6jdC06bc.

The Ateios work has attracted the attention of the National Security Innovation Capital (NSIC) in Mountain View, Calif., which awarded Ateios a $2.4 contract to develop the technology further while ensuring a domestically sourced supply chain.

A key driver of military energy demand has been the massive increase in electronics on the battlefield -- radios, GPS, night vision, drones, and weapons.

Over the last 20 years, the power demand for an average Army platoon has increased 15-fold, from 2.07 kilowatt hours to more than 31.35 kilowatt hours for a typical three-day mission -- nearly equivalent to the daily consumption of an American household.

Related: Energy storage for military applications faces demands for more power

Energy density and safety concerns limit today’s lithium-ion batteries. The primary challenge stems from the flammable solvents in the electrolyte, which can ignite during thermal runaway events or if bullets penetrate the battery.

To address this, Ateios and the Army Research Laboratory have developed a safe semi-solid state electrolyte system to improve lithium-ion battery safety by preventing catastrophic fires in the event of failure.

Existing battery manufacturing relies heavily on processes that require extreme conditions such as heat, pressure, and flammable solvents, which are incompatible with these safe, semi-solid electrolytes.

For more information contact Ateios Systems online at https://ateios.com, or the Army Research Laboratory-Adelphi at https://arl.devcom.army.mil/who-we-are/locations/alc/.