Designers seek to define new flow-control technologies to replace traditional aircraft control surfaces

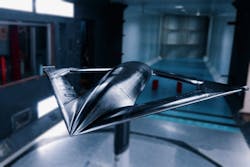

ARLINGTON, Va. – Electric aircraft designers at Lockheed Martin Corp. are moving forward with a project to push the bounds of future electric aircraft by eliminating control surfaces like ailerons, rudders, and flaps.

Officials of the U.S. Defense Advanced Research Projects Agency (DARPA) in Arlington, Va., announced a $12.1 million order to the Lockheed Martin Aeronautics segment in Fort Worth, Texas, last Thursday to move to phase-one of the Control of Revolutionary Aircraft with Novel Effectors (CRANE) project.

Lockheed Martin joins Aurora Flight Sciences Corp. in Manassas, Va. on the CRANE phase-one effort. Aurora won a $12.4 million order for this job last June.

In this phase electric aircraft experts from Lockheed Martin and Aurora Flight Sciences will validate analytical predictions, carry out control loop analyses, and perform modeling verification.

Instead of using ailerons, rudders, and flaps for control surfaces on future electric aircraft, the CRANE project seeks to use actuators or effectors to add energy or momentum to the flow of air over the aircraft.

In the future the CRANE project will move to testing integrated subsystem components, and then fabricate, assemble, ground-test, and flight-demonstration.

Aurora and Lockheed Martin engineers are trying to inject a disruptive technology early in aircraft design with new flow-control technologies and design tools. The idea is to configure and optimize an aircraft with active flow control to enhance efficiency and effectiveness of new commercial and military aircraft.

Passive control involves geometrical modifications like vortex generators on an aircraft wing for flow separation control, or chevrons on an exhaust nozzle of an aircraft to mitigate noise. Passive control devices always are on, no matter the need or performance penalty.

Active flow control, on the other hand, involves energy or momentum addition to the flow in a regulated manner. It is more desirable than passive control because aircraft pilots can turn it on or off as necessary.

Active flow control alters the aircraft's aerodynamic flow field through mechanical actuators, or by ejection or suction on a wing, fuselage, inlet, or nozzle.

Effectors and actuators typically are the enabling technologies of active flow control, yet have been the weakest link in developing active flow-control technology. Despite their relatively high costs, effectors and actuators typically are light weight, have no moving parts, and are energy-efficient.

Aurora and Lockheed Martin are demonstrating new active flow control on an X-plane, with a focus on the best ways to develop and flight demonstrate their flow-control technologies on a clean-sheet design or modification of an existing aircraft.

The CRANE project excludes large external moving surfaces like ailerons, rudders, flaps, elevators, and trim surfaces; mechanical vectoring of engine jet exhaust, or other traditional moving aerodynamic control devices.

CRANE's goal is to demonstrate in flight that active flow-control actuator technologies can maintain flight safely, and provide quantifiable aircraft capabilities.

On this order Lockheed Martin will do the work in Fort Worth, Texas; Chicago; Niskayuna, N.Y.; Pontiac, Mich.; Columbia, Md.; Tulsa, Okla.; and East Hartford, Conn, and should be finished by May 2022. For more information contact Lockheed Martin Aeronautics online at www.lockheedmartin.com, Aurora Flight Sciences at www.aurora.aero, or DARPA at www.darpa.mil.