Draper researchers find new way to ruggedize electro-optics to create PNT systems for harsh environments

CAMBRIDGE, Mass. – Engineers at the Charles Stark Draper Laboratory Inc. in Cambridge, Mass., have developed new techniques to ruggedize electro-optical components for assured positioning, navigation and timing (PNT) systems that must operate in environments with extreme temperature, shock, and vibration.

Harsh environments tend to have large temperature swings and high amounts of shock and vibration, Draper experts say. Such dynamic environments can compromise the performance of electro-optics assembled and packaged for less-dynamic environments.

The U.S. military relies on PNT data for many kinds of missions, systems, and weapons. Information from PNT data especially can be critical in aerospace and defense applications where Global Positioning System (GPS) satellite signals are unavailable.

Draper experts say the electro-optical devices embedded within PNT devices such as the interferometric fiber-optic gyroscope (IFOG) can benefit from new manufacturing methods to support applications in harsh environments.

Related: Wanted: optical clocks to provide PNT without GPS signals

Draper researchers have made a technological breakthrough in ruggedizing PNT systems by reducing the complexity, labor requirements, and manufacturing costs of assembling and packaging electro-optics. This makes them suitable for systems intended for operation in harsh environments.

The new approach is an advance on the current assembly method that relies on robotic alignment and bonding of several optical components and individual miniature mounts to a ceramic substrate, Draper officials say.

Traditional electro-optical manufacturing can make components vulnerable extremes in temperature, shock, and vibration because it relies on adhesives to bond components to a substrate. These adhesives tend to be gooey, sensitive to temperature and humidity, and difficult to dispense and manipulate at the microscale.

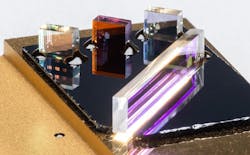

Instead, Draper researchers used the company's in-house microfabrication facility to fabricate silicon optical benches, which are wafer-level platforms composed of precision-etched surface features. This approach uses a passive alignment method that requires fewer steps.

Related: Orolia to provide PNT for hypersonic missile-defense radar

Draper's method enables electro-optical component designers to drop several lenses and beam splitters onto the etched silicon surface. It uses pieces of solid glass frit that melt at low temperatures. These pieces are prefabricated into 3-D shapes like rectangular blocks and circular doughnuts.

These 3-D shapes register and anchor the optical components, and then simultaneously fuse them in a one melt-and-cool step. This new process replaces the slow and expensive combination of precision robotics and liquid adhesives.

The new capability represents a new way to assemble several microscale optical components closely together in one device, says Gilbert Feke, Draper's technical director of the project.

The new method is available to Draper's customers. Draper funding the work was funded by Draper and its internal research and development program. For more information contact Draper online at www.draper.com.