Motorized rotary stage for motion control in laser positioning and machining introduced by OES

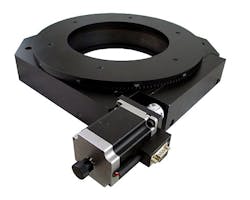

VAN NUYS, Calif. – Optimal Engineering Systems Inc. (OES) in Van Nuys, Calif., is introducing the AY110-300 motorized rotary stage for laser positioning and machining, scribing, microscopy, testing, assembly, inspection, alignment, and other critical applications.

The rotary stage features a 180-millimeter open aperture. This hollow-core precision large open aperture low profile rotary stage is 65-millimeters high and it's foot print is 303 by 319 millimeters, not including the motor.

The rotary table of the stage has a precise pattern of threaded holes for mounting custom tooling and fixtures, and holes in the base for integration into new and existing applications.

The diameter of the rotary table is 300 millimeter and the range of travel is 360 degrees, and the motion control device is capable of continuous rotation. The table is driven by a smooth 288:1 worm gear and has a resolution of 0.000625 degrees with a 10 micro-step per step stepper motor driver.

Related: Motorized three-axis gimbal mount for lasers, optics, and instruments introduced by OES

The AY110-300 rotary stage also is available with a servo motor and optical encoder. The standard model is equipped with stepper motor and a knob for manual adjustment which can be replaced with an optical encoder for precision position verification.

The low cost, low profile AY110-300 Rotary Stage features a very low backlash of 0.0005 degrees, and a positional accuracy of 0.001 degrees.

This black anodized device has a load capacity of 143 pounds and has an indicator scale for visual sighting of the angle of rotation. For more information contact Optimal Engineering Systems online at www.oesincorp.com.

Ready to make a purchase? Search the Military & Aerospace Electronics Buyer's Guide for companies, new products, press releases, and videos