Modeling-based wiring harness design and development tools to speed manufacturing introduced by Zuken Vitech

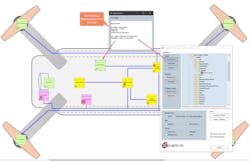

BLACKSBURG, Va. – The Vitech subsidiary of Zuken USA Inc. in Blacksburg, Va., is introducing the E3.GENESYS Connector model-based wiring harness design process to fill the design gap that previously required the manual translation of the product model into schematics and spreadsheets.

The E3.GENESYS Connector joins the product model to the wiring harness design and development process, saving time and making the most of return on investment (ROI), company officials say.

A key benefit of the model-based approach is the elimination of design errors due to the relational nature of the product specification. The model-based approach replaces design specification documents with a product model. A product model is a more rigorous way of describing a product than an unrelated assortment of documents, spreadsheets, and diagrams.

Related: Army chooses Connectec to provide contract manufacturing for Army mortar equipment

E3.GENESYS Connector eliminates the need to translate the model into design documents by connecting the model to E3.series for wiring harness design. The wiring harness design team using E3.GENESYS Connector transfers the specific subsystem or component and exposes the requirements, diagrams, and constraints within the E3.series design environment.

A product model disconnected from the product life cycle raises the risk of divergence between the model and the implementation. The result is a product that may not perform as initially defined. Once the model is in development, it must remain relevant and active throughout the product life cycle. E3.GENESYS Connector preserves that connection.

For more information contact the Vitech subsidiary of Zuken USA online at www.zuken.com.