The U.S. Army’s Future Combat Systems program will integrate unmanned ground vehicles into a future force; if the drones currently used by soldiers deployed in Iraq for reconnaissance and surveillance missions are any indication autonomous ground vehicles promise to be a major paradigm shift in ground warfare.

BY JOHN McHALE

Unmanned aerial vehicles such as the U.S. Air Force Predator garner most of the headlines in the world today, but unmanned ground vehicles (UGVs) are beginning to change the way ground force commanders prepare for battle.

“Robots are fearless,” says retired Navy Vice Adm. Joe Dyer, executive vice president and general manager of iRobot’s Government & Industrial Robots division in Arlington, Va. They can go into areas where soldiers would end up being casualties.

They are already playing a role in battle today in Iraq, and as part of the U.S. Army’s Future Combat Systems (FCS) program will dominate battlefields of the future, Dyer says. The FCS program has 21 different types of vehicle elements, 13 of which are unmanned, he adds.

Lockheed Martin Missiles and Fire Control experts are developing the Multifunction Utility/Logistics and Equipment (MULE) unmanned ground vehicle for the Army’s Future Combat Systems program.

In the battlefield, FCS will link soldiers with manned and unmanned ground and air platforms and sensors. Ultimately, FCS will allow U.S. troops to be fast and versatile, as part of the Pentagon’s vision of the Future Force Warrior. For more information, see www.boeing.com/fcs.

The troops love UGVs in Iraq and Afghanistan for severe environments and want more combat-capable ones as soon as possible, says Brad Curran, senior analyst at Frost & Sullivan’s San Antonio office. Plans are being discussed to add weapons capability to UGVs-such as 0.50-caliber machine guns and grenade launchers, he adds.

Down the road there will be even bigger UGVs that can form a supply route to reduce the risk of casualties from improvised explosive devices (IEDs) that are causing so many deaths in Iraq, Curran says.

“The National Defense Authorization Act of 2001 set the goal that by 2015, one-third of the operational ground combat vehicles of the Armed Forces be unmanned,” Dyer says. Among the U.S. Department of Defense (DOD)-funded projects iRobot is working on to help achieve this goal is iRobot Swarm.

The iRobot Swarm project was sponsored by the U.S. Defense Advanced Research Projects Agency (DARPA) in Arlington, Va. “It represents the state of the art in algorithms, hardware, and user interfaces for large swarms of autonomous robots,” Dyer continues. “The goal of the Swarm project was to develop distributed algorithms for robotic swarms composed of hundreds of individual robots. Our algorithms are designed to be completely scalable, and to function with groups of 10 to 10,000 robots, and the development platform is the world’s largest swarm, with more than 100 individual robots.”

A big advantage of UGVs is the amount of payloads-weapons and sensors-that can be placed on them because they are digital platforms, Dyer says. In this manner they are much like the “F-18 EF, which has about 30 different weapons and sensor payloads on a digital platform.”

Under FCS three types of revolutionary UGVs are envisioned: the iRobot Small Unmanned Ground Vehicle (SUGV), the BAE Systems Armed Robotic Vehicle (ARV), and the Lockheed Martin Multifunction Utility/Logistics Equipment (MULE).

SUGV

“iRobot has a $51.4 million contract to develop the FCS Small Unmanned Ground Vehicle, a smaller, lighter successor to the combat-proven, man-portable PackBot,” Dyer says. The FCS SUGV will be a portable, reconnaissance, and tactical robot that can enter and secure areas that are difficult to access or too dangerous for humans.”

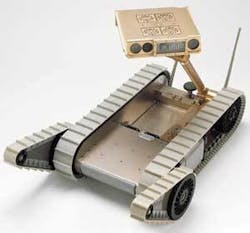

The iRobot SUGV-based on the company’s PackBot-will weigh less than 30 pounds, so a single soldier can easily carry and deploy it in the battlefield using a standard backpack. Using familiar PackBot subsystems, the SUGV will carry as many as seven different payloads, and have enough mobility to carry those sensors through caves, tunnels, and drainage pipes.

Dyer says the SUGV is part of FCS Spiral 3, scheduled to be fielded in 2012. However, because it is ahead of schedule the Army might speed up deployment of the SUGV.

BAE Systems is design the Armed Robotic Vehicle (ARV) for the U.S. Army’s Future Combat Systems program. The semi-autonomous ARV is the largest unmanned ground vehicle in the Army’s Future Combat Systems (FCS) program, and will be an integral platform within platoons and companies in the FCS-equipped Brigade Combat Teams.

iRobot has also added radios and integrated computers so it will be compliant with the Joint Tactical Radio System (JTRS), which will enable the robot to be a data node on the network. At a recent Expeditionary Force experiment, soldiers said iRobot’s PackBot was the single best piece of technology they used for urban warfare, Dyer says.

“The iRobot PackBot family also includes the more specialized PackBot Explosive Ordnance Device (EOD) bomb disposal robot and the PackBot Scout reconnaissance robot, which are used daily in Iraq and Afghanistan to safely disarm improvised explosive devices and search buildings, caves, and tunnels for the presence of hostile forces,” Dyer says. “PackBot Explorer’s new intelligent surveillance equipment includes three cameras, and greater flexibility to customize with sensors and other tools. These tools give soldiers and first responders excellent situational awareness, so they know what to expect and can decide how to respond in dangerous or inaccessible areas.”

iRobot’s Packbot has been huge in helping diffuse EOD in Iraq and there is even talk of adding nuclear, chemical, and biological sensing capabilities to it in the future, Frost’s Curran says.

PackBots also use electro-optical infrared (EOIR) sensors from Insight Technology of Londonderry, N.H. Those tools allow soldiers to assemble PackBot as a scout version for reconnaissance missions, complete with laser rangefinders and night-vision illuminators.

iRobot is also working on a 200-pound-class robot that can “run a four-minute mile,” Dyer says. It has such dexterity that it doesn’t need to be transported but can follow troops along on their movements even lugging some of their equipment for them, he adds.

The ARV

The ARV, the largest of the three, has two variants: the assault variant, and the reconnaissance, surveillance, and target acquisition variant, BAE officials say. These systems are in development and will be key elements in the FCS System of Systems, providing greatly enhanced operational capability in the FCS-equipped Brigade Combat Teams-the Army’s future tactical warfighting echelon.

BAE Systems is developing UGV programs in Santa Clara, Calif., and York, Pa. The ARV will be about the size of a large pickup truck and will be deployable either two at a time on C-130 airplanes or individually with CH-47 helicopters.

A key capability for the ARV is the reconnaissance, surveillance, and target acquisition (RSTA) sensor suite, providing long-range standard and thermal imagery, as well as laser targeting capability, BAE Systems officials say. The RSTA suite is mounted on a telescoping mast incorporated in the two variants of the ARV in development. The two variants will share a common chassis.

The ARV reconnaissance, surveillance, and target acquisition variant (ARV-R) will be assigned to FCS platoons equipped with mounted combat systems and reconnaissance and surveillance manned ground vehicles. The ARV-R will feature a RSTA mast, carry a cannon for self-defense, disperse unattended ground sensors and conduct battle damage assessments.

The second variant, the ARV Assault (ARV-A), is designed to accompany FCS platoons equipped with Infantry Carrier Vehicles. The ARV-A integrates long-range beyond-line-of-sight (BLOS) missiles, a powerful automatic cannon and a high-rate-of-fire, suppressive machine gun. The assault variant also features an electro-optical/infrared (EO/IR) sensor on a mast.

The Autonomous Navigational System (ANS) and Automatic Target Recognition (ATR) will provide the ARV with the capability to operate semiautonomously with minimal input from the operator. Soldiers will deploy and control the ARVs at extended ranges.

Crusher represents a new class of unmanned ground combat vehicles developed under the DARPA/Army UGCV-Perception for Off-Road Robots Integration program.

The ARV will be controlled from operator crew stations located inside manned ground vehicles or by FCS-Land Warrior-equipped dismounted soldiers with a control device. The core technologies enabling semiautonomous operation will allow one soldier to control all aspects of the vehicle remotely. The ARVs will feature additional capabilities including chemical detection, anti-tampering, and battle command and communications equipment.

BAE Systems is in the system design and development (SDD) phase of the FCS ARV program. Under this effort, the company will test the first prototypes in 2010, with fielding to FCS-equipped units of action scheduled for 2012-2014.

Subcontractors include the General Dynamics robotics system division in Westminster, Md., and Omnitech Robotics in Englewood, Colo. The process is managed by the Tank-Automotive Research, Development and Engineering Center (TARDEC) at the Army’s Tank-automotive and Armaments Command (TACOM) in Warren, Mich.

MULE

Lockheed Martin Missiles and Fire Control experts in Dallas are developing the Multifunction Utility/Logistics and Equipment (MULE) UGV. The 2.5-ton MULE includes three variants. Like the Army mule, one version will haul equipment for two infantry squads. Another variant will detect and mark land mines. Finally, the Air Assault MULE will have “teeth,” being armed with a rapid-fire gun and antitank weapon.

“The MULE is a key component of the FCS system of systems with its high versatility and unique mobility,” says Gene Holleque, director of Unmanned Systems at Lockheed Martin Missiles and Fire Control. “This family of vehicles will increase the warfighters’ survivability and the efficiency of the total force by complementing, not replacing, man and manned platform functions.”

The MULE/ARV-A(L) provides for future growth through spiral development and possesses an open architecture. A recent contract modification increased the number of prototypes being delivered from 17 to 19, with the first prototypes delivered in the third quarter of 2010. Deliveries will consist of Transport, Armed Robotic Vehicle-Assault Light (ARV-A(L)) and Countermine variants, with final deliveries in spring 2011.

The MULE has an advanced six-by-six independent articulated suspension. Coupled with in-hub motors powering each wheel, the suspension system provides extreme mobility in complex terrain, far exceeding that of vehicles utilizing more conventional suspension systems, Lockheed Martin officials say.

It will climb at least a one-meter step and provides the vehicle with the mobility performance and surefootedness required to safely follow dismounted troops over rough terrain, through rock and debris fields, and over urban rubble. This technology also enables the vehicle to cross one-meter gaps, traverse side slopes greater than 40 percent, ford water to depths more than about two feet, and overpass obstacles as high as two feet, while compensating for varying payload weights and center of gravity locations.

The Transport MULE configuration is designed to support the Future Force soldier by providing the volume and payload capacity to carry the equipment and supplies to support two dismounted Infantry Squads, Lockheed Martin officials say. Multiple tie-down points and removable/foldable side railings will support nearly any payload variation. It is suited to support casualty evacuation needs as well.

The ARV-A(L) version will be armed with a line-of-sight gun and an anti-tank capability, providing immediate, heavy firepower to the dismounted soldier. The Countermine variant is designed to provide detection and neutralization of mines, and marking of cleared lanes through minefields.

Crusher

FCS experts will be taking advantage of recent developments of the Crusher UGV from researchers at DARPA, the Army, and Carnegie Mellon University’s National Robotics Engineering Center in Pittsburgh. The team has designed the Crusher unmanned ground vehicle as a follow-on and upgrade to the Spinner vehicle that was developed in a prior DARPA/Army program.

Crusher is a six-wheeled, all-wheel drive hybrid electric, skid-steered, UGV. The vehicle weighs 14,000 pounds fully fueled, and is designed to carry a 3,000-pound payload-at this 17,000 pound total weight, two Crusher vehicles can fly aboard a C-130H aircraft at substantial range. If desired, crusher can carry as much as 8,000 pounds of payload and armor without compromising its mobility.

Crusher represents a new class of unmanned ground combat vehicles (UGCVs) developed under the DARPA/Army UGCV-Perception for Off-Road Robots Integration (UPI) program. Crusher is a mobile vehicle designed from the outset to be unmanned. It is being equipped with state-of-the-art perception capabilities, and will validate the key technologies necessary for a UGV to perform military missions autonomously. Crusher will be equipped with representative sensing and weapons payloads for planned field experiments.

“The technologies embodied in the Crusher vehicles provide a glimpse into the future of autonomous ground platforms. The Crusher and its predecessor, the Spinner, demonstrate the realm of the possible with regard to a combination of autonomous behaviors, hybrid electric propulsion and robust vehicle design,” says Thomas Killion, deputy assistant secretary of the Army for research and technology. “All of this combines to give the soldier greatly enhanced standoff capabilities with minimum impact on workload.”

“The Future Combat Systems Brigade Combat Team (BCT) program has been working with DARPA’s UPI program for some time now, leveraging their advancements in robotics field testing, perception algorithm development, autonomy, and more recently, in understanding wheeled system design characteristics for mobility and remote control latency and bandwidth effects on mobility performance,” explains Maj. Gen. Charles Cartwritght, program manager Future Combat Systems BCT.

“The FCS BCT, lead systems integrator, and platform providers have all witnessed and participated in the dialog with DARPA and Carnegie Mellon University’s National Robotics Engineering Center related to Spinner and now Crusher experimentation. This interaction has been of great benefit to the FCS program, and we look forward to continued interaction and transition of technologies from this new vehicle system to our FCS UGV systems.”

“The two new Crusher vehicles are a major improvement in unmanned ground vehicle capability,” says Larry Jackel, DARPA UPI program manager. “The original Spinner UGCV is an excellent platform, but in shakeout experiments, the new Crushers have already outperformed Spinner in all aspects.”

The UPI program will conduct field experiments of the two Crusher vehicles and their perception and payload systems, with experiments planned at Fort Carson, Colo., this summer. The program will culminate in 2007 with Army users operating Crusher vehicles during representative missions in natural terrain. The UPI effort will merge all Crusher functions-mission planning, perception monitoring, vehicle monitoring, and payload operation) into and operator workstation interface and determining interaction requirements via experimentation.

UPI is a joint program of DARPA and the Office of the Assistant Secretary of the Army for Acquisition, Logistics, and Technology, managed by DARPA’s Tactical technology Office. The Army’s Program Manager Future Combat System (Brigade Combat Team) closely follows the program.

Carnegie Mellon University’s National Robotics Engineering Center is the prime contractor for Crusher. Key subsystems and components are provided by CTC Technologies (vehicle hull chassis structure), Timoney Technology (suspension systems), Saft America (lithium-ion battery pack), and UQM Technologies (electric drive motors).

DARPA announces third grand challenge

The Defense Advanced Research Projects Agency (DARPA) in Arlington, Va., announced plans to stage its third Grand Challenge competition on Nov. 3, 2007. The DARPA Urban Challenge will feature autonomous ground vehicles executing simulated military supply missions safely and effectively in a mock urban area. Safe operation in traffic is essential to U.S. military plans to use autonomous ground vehicles (AGVs) in mission-critical situations.

DARPA officials will award prizes for the top three (AGVs) that compete in a final event where they must safely complete a 60-mile urban area course in less time than six hours. First prize is $2 million, second prize is $500,000, and third prize is $250,000. To succeed, vehicles must autonomously obey traffic laws while merging into moving traffic, navigating traffic circles, negotiating busy intersections and avoiding obstacles.

“Grand Challenge 2005 proved that autonomous ground vehicles can travel significant distances and reach their destination, just as you or I would drive from one city to the next,” says DARPA Director Tony Tether. “After the success of this event, we believe the robotics community is ready to tackle vehicle operation inside city limits.”

To accelerate development of the AGV technologies required for urban operations and to ensure the widest possible participation, DARPA announced two ways for teams to qualify and compete in the Urban Challenge.

The first track involves teams submitting a detailed proposal for as much as $1 million of technology development funds in response to a DARPA solicitation. The government will obtain license rights to technologies developed using this funding. Applicants that do not submit a proposal or are not selected to receive development funds may still compete in the Urban Challenge using the second track.

The second track is similar to that used for Grand Challenge 2005. Teams will submit applications and participate in a series of qualification activities. Each team that participates as a semifinalist in the National Qualification event (NQE) will be awarded $50,000. Each team that is successful at NQE will receive $100,000 and compete in the Urban Challenge final event.

Participants from both tracks will come together at the NQE and progress on to the Urban Challenge final event, where the selected teams will compete for the top three prizes. Details on how to compete for development funding are available n the Urban Challenge solicitation and proposer information pamphlet, available at http://www.fbo.gov/spg/ODA/DARPA/CMO/BAA06%2D36/Attachments.html. The DARPA Grand Challenge web site-www.darpa.mil/grandchallenge-is the primary resource for information about this year’s event.

FCS vehicles to power electronics with hybrid drive

A BAE Systems-led team has been selected by the Future Combat Systems (FCS) One Team to develop the common Traction Drive Subsystem (TDS) for FCS Manned Ground Vehicles (MGVs).

The TDS is a series-hybrid drive system that will provide vehicle propulsion, steering and braking, and regenerate electrical power from braking and downhill grades for use in vehicle electrical systems. Initial deliveries of the objective TDS design are due in October 2006, with deliveries for 45 total TDS units and follow-on support running to 2011.

Under the award, the TDS Team will join the MGV Propulsion Integrated Product Team to work in conjunction with BAE Systems and General Dynamics to develop and fully integrate the propulsion system for the common chassis.

The FCS Lead System Integrator (LSI)-Boeing and SAIC-recognized the source selection team for its detailed analysis of all TDS proposals. The analysis was conducted by integrated MGV One Team partner evaluation panels led by LSI personnel.

Following the analysis, a team led by BAE Systems, along with QinetiQ and Honeywell, was recommended and selected to develop the TDS system. The selection was announced by BAE Systems’ firewalled FCS MGV program, which issued the TDS request for proposal in January.

“We are pleased the FCS One Team selected our approach as the best-value solution for the Manned Ground Vehicles,” says Matt Riddle, BAE Systems’ director of Advanced Development at Santa Clara, Calif. “Our development and integration experience with hybrid systems, combined with QinetiQ’s compact E-X-Drive tracked vehicle transmission and Honeywell’s expertise in power electronics, motor manufacture and controls, will advance this key technology for FCS and other vehicle systems.”

BAE Systems, as part of the firewalled FCS One Team, teamed with General Dynamics, is working to develop and field a family of deployable Manned Ground Vehicles that will be key supporting systems linked through the overarching network that will enable the FCS-equipped Units of Action to effectively complete their missions.

The two companies have formed integrated design teams to develop and demonstrate the family of eight manned ground vehicles featuring a common platform design with common components and subsystems, such as TDS, with unique mission modules and all the variants linked together by networked battle command.

Under the FCS MGV contract, BAE Systems has responsibility for five MGV variants: Non-Line-of-Sight Cannon; Infantry Carrier Vehicle; Medical Vehicle; Non-Line of Sight Mortar, and FCS Recovery and Maintenance Vehicle.