Pushing the bounds of size, weight, and power consumption (SWaP) to design the most rugged and sophisticated on-board sensor and data processing for military unmanned air, land, and sea vehicles

Demand is exploding for sensor capability aboard unmanned vehicles. To a large extent, these unmanned craft represent the eyes and ears of U.S. and allied military forces, and are becoming more so in the future. Top commanders rely on unmanned vehicles to get them the information they need, when they need it, with little or no time lag involved.

Unmanned vehicles also are shrinking in size. Where once the U.S. military relied exclusively on unmanned aerial vehicles (UAVs) the size of jet fighters, today's UAVs often have wing spans no longer than a person is tall and can be launched by catapult, and sometimes even by hand. This trend is continuing with development of UAVs small enough to fit in a warfighter's shirt pocket.

This creates unprecedented design challenges for the embedded computing industry, whose engineers increasingly are being asked to design what essentially are rugged, mobile micro data centers that are small, rugged, powerful, and power-efficient enough for duty aboard the latest generations of unmanned vehicles.

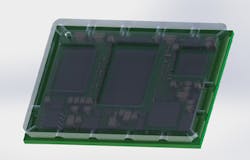

The A176 rugged embedded computer from Aitech Defense Systems has general-purpose graphics processing unit (GPGPU) functionality to provide real-time image recognition for unmanned vehicle surveillance.

"We are seeing an uptick in C4ISR [command, control, communications, computers, intelligence, surveillance, and reconnaissance] applications on unmanned vehicles, with video, electro-optical, and sensor fusion all tied together," says Doug Patterson, vice president of business development and marketing at embedded computing specialist Aitech Defense Systems Inc. in Chatsworth, Calif.

When it comes to unmanned vehicles, the driving mantra of onboard sensor processing for unmanned vehicles is SWaP-C, which is short for size, weight, power consumption, and cost. This pressing need is what keeps embedded systems designers up at night. These systems should be small, lightweight, power-efficient, and cost-effective.

Processing unmanned data

It all begins with on-board data processors, which must handle massive amounts of data coming in from still-image and video cameras, radar, signals intelligence (SIGINT), electronic warfare (EW), electro-optical sensors, and other kinds of surveillance and reconnaissance equipment.

"More processing is required on board unmanned vehicles," says Chris Ciufo, chief technology officer at General Micro Systems (GMS) in Rancho Cucamonga, Calif. "PowerPC was the way we did things 10 years ago. Now we have these data-mining applications on UAVS where you are collecting reams of data from these sensors of large-pixel density, from TV and infrared cameras. There's just lots and lots of data streaming in — terabytes — in real time."

Not only are today's most modern processors powerful, but increasingly they are easier to integrate than previous generations.

"You have the silicon that is much more powerful, and much more user-friendly in terms of programming," says Aitech's Patterson. "The implementation process is almost limitless with the amount of processing that the systems designer has available."

Trends in the miniaturization of processors of many different types has progressed to the stage where they can power shoebox-size, sensor-processing subsystems appropriate for many small- and medium-sized unmanned vehicles. This trend applies to general-purpose central processing units (CPUs), general-purpose graphics-processing units (GPGPUs), vector-processing engines, field-programmable gate arrays (FPGAs), and other components critical to on-board sensor processing.

"Intel, obviously, is a large component of that, but there are other architectures, like ARM, that are growing significantly within military unmanned vehicles," says Mike Southworth, product manager at the Curtiss-Wright Corp. Defense Solutions Division in Ashburn, Va. He also cites GPGPUs from Nvidia Corp. in Santa Clara, Calif., as a popular on-board data processor for unmanned systems.

"Intel has released its first system-on-a-chip for the Xeon processor technology that has enabled power consumption like the company's Core i7 processor, but with more cores — 16 for commercial-temperature applications, and 12 cores for industrial temperatures — with 45 watts of thermal dissipation," Southworth says. "The Intel Xeon D brings together a lot of processing cores, much more memory, and on top of that many more PCI Express and 10 Gigabit Ethernet lanes."

While the Intel Xeon D processor offers server-class performance with multiprocessing capability, matching that chip, or other microprocessors, with the Nvidia GPGPU can speed the processing of incoming sensor video. "You can encode or decode video coming from the sensor, or use the GPGPU as a parallel processor," Southworth says.

The Parvus DuraNET 20-11 from Curtiss-Wright Defense Solutions is an ultra-small-form-factor (SFF) rugged 8-port Gigabit Ethernet switch optimized for demanding manned and unmanned vehicle and aircraft platforms.

Improvements in microprocessors suitable for on-board unmanned vehicle sensor processing are expected continue. "We are starting to see a migration to more cores coming up on the Xeons. We already have seen Xeon D-class processors with four, eight, twelve, and up to sixteen cores in a package," says Peter Thompson, director of business development technology at Abaco Systems in Huntsville, Ala.

Sometimes specialized processors are necessary for image and video processing, and sometimes a combination of specialized processors like GPGPUs and a high-performance, general-purpose processor like the Intel Xeon can fit customer needs.

"On the video side, we are seeing interest in GPGPU," says Aitech's Patterson. "They are seeing the need for small, compact repetitive algorithms distributed among hundreds of processors, if not more. You can break down your video into smaller chunks, process those pixels separately, and then combine them later."

In addition to enhanced processing power, unmanned vehicle sensor processing designers also are gaining access to the Intel AVX-512 technology, which adds 512-bit extensions to the 256-bit Advanced Vector Extensions single-instruction multiple data (SIMD) instructions for x86 instruction set architecture (ISA).

"AVX is Intel's name for its vector-processing engine that it puts on its processors," Thompson says. "It's a side-car on the processor, and is designed to do signal and image processing. AVX gives you the capability to process in parallel. Its parallel vector pipeline enables you to manipulate more data per cycle, so you can do more of whatever it is you are doing."

The S402-LC Mustang rugged and sealed CPU server based on the Intel Xeon E5 processor from General Micro Systems is for aerospace and defense applications that demand SWaP efficiency.

In addition to processing performance, the Intel Xeon offers designers access to a broad range of software support. "If you can use that Xeon ecosystem, you have access to all the software in that ecosystem," says John Bratton, product and solutions marketing manager at Mercury Systems in Andover, Mass.

Networking and I/O

When it comes to transforming raw sensor data into actionable information, pure processing power is only one piece of the puzzle. To run at its optimum speeds, a processor needs the ability to receive data from sensors as quickly as it can process that data.

"You don't want to starve the processor for data," says Mercury's Bratton. "The backplane needs unrestricted fat pipes. We have 10-gigabit or 40-gigabit pipes across 40 channels, and we guarantee the performance."

The sensor-processing system must be able to move data within the system, as well as move data to other on-board systems or to satellite links or ground-based networks. For these tasks, on-board data networking and I/O is essential. "Beyond the processor itself is the ability to move data around on the vehicle faster than ever before," says GMS's Ciufo. "Our customers want 10-gigabit fiber Ethernet on board, so we can add an Ethernet switch to route data throughout the platform. Networking is important, because we are talking about something like an on-board data center."

The bandwidth of data links to the ground or to satellite networks is paltry compared to today's on-board networking that fast Ethernet links provide. "You only have a straw as a pipe to the ground or to the satellite," Ciufo says. It's for this reason that today's on-board sensor-processing systems must be able to handle as much data as possible on the unmanned vehicle itself.

Mercury's Ensemble HDS6603 high-density embedded server offers more than one tera-FLOP of general processing power in an OpenVPX slot. It has two 1.8-GHz Intel Xeon E5-2600 v3 processors, each with 12 cores to deliver image- and video-processing power for unmanned vehicles.

"That fabric for PCI Express and 10-Gigabit Ethernet can enable a lot of interesting capabilities in technologies like 3U VPX, but now we are going much smaller," says Curtiss-Wright's Southworth.

Ultra-small processing also necessitates the smallest possible I/O, Southworth says. "We can port things like additional I/O integrated right in the box," he adds. "MIL-STD-1553 and ARINC-439 databuses and CANbus for ground vehicles are common in these ultra-small-form-factor boxes. They also have open slots to support some add-on interface cards, which are about the size of business cards, that are pre-fitted into these card slots. With this, the generic computer becomes a customizable computer."

The Parvus DuraCOR 312 from Curtiss-Wright Defense Solutions is an ultra-small form factor embedded mission computer built around the NVIDIA Jetson Tegra X2 (TX2) integrated in a miniature rugged chassis with MIL-grade, high-density connectors.

Southworth says customers of Curtiss-Wright typically know how many extra networking and I/O interfaces they need in each sensor-processing subsystem. "We can integrate that in the boxes we make, and the customers will have all the throughput they need." One trusted partner of Curtiss-Wright's for ruggedized MIL-STD-1553 and ARINC 429 avionics databus interfaces is Data Device Corp. (DDC) in Bohemia, N.Y.

One promising data pipe for unmanned sensor processing is Universal Serial Bus (USB) 3.0, Southworth points out. USB 3.0 can transfer data as quickly as 5 gigabits per second. Its successor, USB 3.1, doubles the speed, and can transfer data as quickly as 10 gigabits per second. These data pipes are becoming common on PC laptop and desktop computers.

"When it comes to ruggedization, USB 3.0 takes some special care," Southworth says. "Your cable length for USB 3.0 will not be at its full potential, and you may need shorter cable runs. You need to make sure your connector interfaces can handle the signal from that connection."

Precision timing

A key component of on-board sensor networking is precision timing, such that processors and nodes on the network can be synchronized with nanosecond accuracy.

"Modern processors and communications devices would come to a halt if they weren't able to synchronize their devices," says Curtiss-Wright's Southworth.

One accepted industry standard for network precision timing is the IEEE 1588 precision time protocol (PTP), which helps synchronize clocks throughout a computer network. It is designed for local systems that require accuracies beyond those attainable using Network Time Protocol (NTP), as well as for applications that neither can bear the weight or cost of a separate GPS receiver at each node, nor for which GPS signals are inaccessible.

IEEE 1588 "is an increasing requirement in unmanned vehicle Ethernet networks," Southworth says. It's not just for synchronizing networking nodes, but also for unmanned vehicle navigation in areas where signals from Global Positioning System (GPS) satellites are jammed or otherwise denied.

The military has one program of record called Mounted Assured Position, Navigation, and Timing (MAPS), Southworth says. "The goal is to leverage redundancy in position, navigation, and timing [PNT] by distributing PNT timing," he says. "You have a chip-scale atomic clock to assure precision timing, rather than from a GPS device. It's connected to an Ethernet switch to distribute all this PNT data. The Army and the other services view this as one way to deal with GPS degradation and GPS denial. Assured PNT is validating the truth of where you are and where you're going."

Data storage and memory

There are additional components of unmanned sensor processing. One overriding technology is fast data storage.

The S2002-MD Golden-Eyes II from General Micro Systems offers two isolated rugged servers based on the Intel Xeon-D and removable data storage drives for unmanned vehicles and other small-form-factor applications.

"The mission of a UAV is to collect information the battlefield. Storing the information is hugely important," says GMS's Ciufo. "When we went from rotating media to solid-state drives, things got a lot better."

Solid-state drives fixed a lot of the problems of rotating data storage — especially when it comes to ruggedization, reliability, and size. It does have a downside: "It's more expensive for the density you get," Ciufo says.

Yet data storage continues to improve, and is enabling data storage to be a big contributor of unmanned sensor processing capabilities. One of the most significant advances is Non-Volatile Memory Express (NVMe), which enables systems designers to access non-volatile storage media like the Flash memory in solid-state memory devices via the PCI Express bus. NVMe enables host hardware and software to use parallelism in modern solid-state drives.

NVMe "eliminates the need for a hard disk controller and avoids the latency of accessing the drive directly," Ciufo explains. "The processor can talk directly to the drive, and boosts the performance of streaming data to the drive."

Other advantages of NVMe include its ability to be ruggedized for applications like unmanned vehicles, as well as its ability to carry out fast data encryption and decryption. "You can buy NVMe drives that do multi-encryption on the fly, and we are doing that as well," Ciufo says.

Mercury Systems engineers are addressing SWaP in on-board data storage with a 3D stacking technique for flash memory in solid-state memory devices. On-board sensor processing "relies on vast amounts of memory, and memory takes up space," says Mercury's Bratton.

"On the Xeon boards, we are doing dense memory stacks and reducing the footprint the memory takes on the board by about 90 percent," Bratton says. "We connect the memory to the board with BGA packaging. It is very dense and rugged memory attached to the board."

Mercury Systems uses special hardening to ruggedize high-performance embedded computing sufficiently for use in unmanned vehicle sensor-processing subsystems.

Another benefit to Mercury's rugged on-board, solid-state memory in its high-performance Xeon embedded computing boards is the technology's intense level of ruggedization. "We have experience in smart munitions," Bratton explains. "We can make these stacked chips gun-hardened, and we can leverage this technology to make these payloads quite small."

Power and thermal management

Dense, powerful computing sized small enough for on-board unmanned sensor-processing payloads can have two substantial drawbacks: substantial power requirements, and difficulty to cool. Hence, power and thermal management on unmanned sensor-processing payloads need to be considered up-front in any system design.

"These systems need massive processing, and are very dense down to the memory, so cooling is critical," says Mercury's Bratton. "Mercury's air flow-by and liquid flow-by technologies helps our boards run cooler."

Air flow-by, reflected in the VITA 48.7 open-systems standard, involves cooling and sealing technologies for VPX and VPX REDI embedded computing systems. It uses convection heat transfer to cool plug-in modules while shielding circuit boards and backplanes from the cooling air with plate with apertures for backplane connectors over the backplane.

Liquid flow-by, meanwhile, enables open-systems modules to operate unrestricted and reliably, regardless of the presence of a cooling air supply. It integrates liquid-cooling capability to remove about 50 percent more heat than pure air-cooled approaches.

Liquid flow-by thermal management can use an unmanned vehicle's own fuel as a cooling liquid. Fuel enters each module through non-drip, quick disconnects to complement or take over the native air cooling capability of each module. Non-drip technology makes each module and supporting chassis a self-sealing entity, which is critical for liquid cooled subsystems, especially when the coolant is fuel. In the absence of cooling air, the coolant takes over completely.

In addition to cooling, unmanned vehicle sensor payloads are starting to rely in a variety of digital power control architectures to help squeeze out every bit of capability for a given source of power — especially when the vehicle makes broad use of battery power.

Smart power management can help balance power loads over the whole vehicle — including separate networked sensor payloads — and even borrow power from systems with light power demands to help systems under intense power loads.

Security, safety, and trusted computing

Those specifying unmanned vehicles and on-board sensor payloads increasingly are demanding special provisions that guarantee safe operations of these unmanned systems alongside manned craft, guarantee performance under demanding circumstances, ensure that software and hardware do not interfere with one another to produce errors and faults, and that guard against the intentional insertion of malware to disrupt or bring down computer operations.

"Security isn't optional anymore; it needs to baked into all these solutions," says Mercury's Bratton. "With more of the sensor chain on board, security has to be part of sensor, processing, data storage, and back again." The sophistication of unmanned sensors and sensor processing also is bringing artificial intelligence and decision-support aboard unmanned vehicles. "The sensors themselves are starting to make decisions, and safety-certifiable is starting to be critical," he says.

The GVC2000 from Abaco Systems is a mission or graphics computer intended for symbol generation, mission computing, demanding graphics generation applications, and GPU-accelerated data processing.

Trusted computing doesn't only deal with shielding against viruses and other malware. It also involves allocating and balancing computer resources so life- and mission-critical functions take priority over other non-critical tasks. It also uses built-in routines to prevent the inadvertent corruption of computer data or instructions from unanticipated system transactions, and the accidental dissemination of data that should remain private to the system.

"Everything these days has sensors, and produces a deluge of information," says Mercury's Bratton. "This uses a cloud-like model, where information feeds to a server that can manage the information, take information out, and parcel it out to users that need it."

One way of keeping everything straight is the use of software hypervisors. "Security architectures use hypervisors that separate command-and-control, data acquisition, and other functions," says Erik Kramer, product manager at Mercury Systems. "You can separate functionality by hypervisor to privacy and security concerns. If one domain fails, using hypervisors guarantees that it doesn't bring the whole system down."

The same principle applies to separate parts of a sensor-processing system that might be overworked. "If one function in a system is challenged at the moment, you can use hypervisor technology for guaranteed levels of performance reserved for other functions that are critical," Kramer says.