AOSense to develop navigation chip that combines solid-state and atomic inertial sensors

WRIGHT-PATTERSON AFB, Ohio, 11 April 2013.Navigation and guidance experts at AOSense Inc. in Sunnyvale, Calif., are building experimental navigation-system-on-a-chip that combines traditional, solid-state, and atomic inertial guidance technology to reduce the U.S. military's reliance on Global Positioning System (GPS) satellite guidance for advanced munitions, mid- and long-range missiles, and other weapons.

AOSense engineers are developing technology that combines solid-state and atomic inertial measurement units on the same chip under supervision of the U.S. Defense Advanced Research Projects Agency (DARPA) in Arlington, Va.

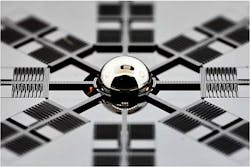

On behalf of DARPA, the U.S. Air Force Research Laboratory at Wright-Patterson Air Force Base, Ohio, awarded AOSense a $2.1 million contract earlier this month for the DARPA Chip-Scale Combinatorial Atomic Navigator (C-SCAN) program, which seeks the co-integration of inertial navigation sensors with different kinds of physics on one micro-scale inertial measurement unit (IMU), which addresses challenges of long-term drift, dynamic range, and component start-up time.

Potential applications for these kinds of advanced navigational sensor chips are smart weapons, positioning, targeting, navigation, and guidance. The idea not only is to wean U.S. weapon systems off the use of GPS, but also to create an inertial sensor on a chip that works reliably without noticeable drift for minutes or hours.

“Platforms such as missiles rely on GPS for a variety of information,” says Andrei Shkel, the C-SCAN program manager at DARPA. “When GPS is not available gyroscopes provide orientation, accelerometers provide position and oscillators provide timing. The new C-SCAN effort focuses on replacing bulky gyroscopes with a new inertial measurement unit that is smaller, less expensive due to foundry fabrication and yields better performance.”

Today's state-of-the-art microscale inertial instruments can provide the precision necessary for missions for only 30 seconds or less, DARPA officials explain. The micro-PNT program is developing chip-scale, small size, weight, power, and cost, inertial sensors for missions ranging from minutes to hours.

Military reliance on GPS signals for precision positioning, navigation, and timing (PNT) information is crucial for a wide range of military weapons, DARPA officials point out. Yet when GPS is inaccessible due to component or system malfunction or enemy jamming, only on-board IMU technology can guide the weapon to its target.

DARPA wants AOSense to explore how shrink and fabricate atomic sensors together with high-performance solids-state inertial sensors. The chip should be no larger than 20 cubic centimeters and consume no more than one Watt of power.

DARPA officials say they expect the C-SCAN program to lead to a breed of inertial microsystems, with a wider range of operating conditions and greater immunity to the environment, reduced start-up time, increased sensitivity, and improved bias and scale factor stability.

The contract to AOSense is the first of what may be several contracts for the C-SCAN program, DARPA officials say. C-SCAN is part of DARPA’s micro-PNT program (microtechnology for positioning, navigation, and timing) to develop technologies for self-contained chip-scale inertial navigation and precision guidance that could eliminate the dependence on GPS or any other external signals for uncompromised navigation and guidance of military weapons.

Micro-PNT work revolves around chip-scale precision timing devices and inertial sensors, including chip-scale atomic clocks, chip-scale primary atomic clocks, solid-state oscillators, silicon accelerometers, vibratory rate gyroscopes, rate integrating gyroscopes, electrostatically levitated spinning mass gyroscopes, and micro nuclear magnetic resonance gyroscopes.

Despite micro-PNT work to date, challenges remain. Vibratory gyroscopes can achieve the required level of bandwidth and frequency of measurements, for example, but they have limited resolution and poor long-term stability. Atomic sensors have excellent resolution and bias stability, but are limited in bandwidth and generally do not allow high-frequency measurements.

The warm-up and integration times for different type of clocks and inertial sensors, moreover, also vary broadly, from seconds for mechanical vibratory devices to tens of minutes for atomic devices.

An IMU device for weapons guidance must warm-up period and reach its optimal readout characteristics quickly. The expected turn-on time of the Hellfire air-to-surface missile, for example, is about five seconds. Achieving 20 minutes of free inertial guidance is a major technological challenge.

For the C-SCAN program, DARPA scientists want AOSense to work on technologies involving combinatorial chip-scale clock; cold-atom technology on the micro-scale; chip-scale nuclear magnetic resonance (NMR) gyroscopes; and IMU based on cold-atom interferometry.

Current versions of atomic inertial sensors suffer from several drawbacks, such as extremely long warm-up time (tens of minutes), long integration time to reach an optimal reading (thousands of seconds), and instrumentation that is very complex, bulky, and power hungry, DARPA officials say.

In contrast, solid-state inertial sensors are very compact (tens of cubic millimeters), with short warm-up times (seconds), fast integration times (seconds), and low power consumption (milliwatts). In addition, solid-state sensors can be instrumented with exceptional responsiveness, large bandwidth, and a broad dynamic range of operation. However, the major drawback of solid-state inertial sensors is the loss of long-term bias and scale-factor stability.

For more information contact AOSense online at www.aosense.com, or DARPA at www.darpa.mil.