Circuit board rework system with automatic residual solder removal in electronics repair introduced by Esra

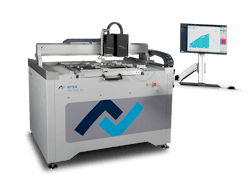

KREUZWERTHEIM, Germany – Esra GmbH in Kreuzwertheim, Germany, is introducing the HR 600P table-top rework system for electronics repair that enables system maintainers not to dispose of faulty boards.

The system with automatic residual solder removal has a solid and accurate machine frame for precise component placement and reliability.

Infrared heating

Reproducible soldering comes by infrared heating elements in the bottom-side emitter, which heat the assembly. The dynamic hybrid heating head ensures targeted and efficient component heating from above by combining infrared radiation and convection heating.

Related: The danger of hybrid-solder boards

High-precision thermocouples or the non-contact, digital Virtual Thermocouple (VTC) can be used for closed-loop temperature control. The exact component position is calculated automatically, and the component is placed with a vacuum gripper via the precise axis system.

A reflow process camera with LED illumination helps with monitoring and documentation. The HRSoft 2 operating software for Windows monitors and documents all operations. The HR 600P also can connect to customer MES systems via HRSoft 2.

The HR 600P circuit board rework system is available in different versions -- one with a large printed circuit board holder that enables the user to process assemblies as large as 642 by 423 millimeters.

Related: The move to lead-free solders has its own challenges and hidden problems

A version with a lowered heating cassette creates additional free space on the underside of the assembly for tall structures. The HR 600 P is prepared for use with the Esra DIP&PRINT STATION, which applies a defined amount of flux or solder paste to the components.

Residual solder removal

The system's optional Auto Scavenger SC 600 scavenging module can remove the solder remaining on the circuit board after desoldering in an automated process without touching the circuit board surface. The scavenging module can be retrofitted to the HR 600 P and is integrated into the into the HRSoft 2 software.

For more information contact Esra online at www.kurtzersa.com/products/electronics-production/overview.