Case Study: EP21TDCS-LO: A Conductive Bonding Agent for Space-Environment Assemblies

Conductive bonding agents play a fundamental role in ensuring reliable electrical connectivity in many electromechanical assemblies designed to operate at the extremes of temperature and pressure of space. Failure of a single bond between conductive components in an assembly can ripple rapidly through mechanical and electrical systems, ultimately threatening spacecraft integrity and crew safety. In two applications, Master Bond EP21TDCS-LO conductive epoxy met critical requirements for maintaining robust bonds in electromechanical systems intended to operate in space conditions.

Master Bond Polymer System EP21TDCS-LO is a two component, silver-filled epoxy designed to ensure high-strength conductive bonds between dissimilar materials at temperatures down to 4K. Unlike most two-part silver-filled adhesives, Master Bond EP21TDCS-LO uses a simple one-to-one mix ratio that remains workable for 30-40 minutes and cures at room temperature in 24-48 hours or in 1-2 hours at 200°F. With volume resistivity less than 10-3 ohm-cm, this adhesive cures to an electrically conductive bond that combines high strength (shear strength over 850 psi) and flexibility (T-peel strength over 5 pounds per linear inch) – properties unusual in a silver epoxy. Along with its workability and performance characteristics, Master Bond EP21TDCS-LO meets critical requirements for space operations including passing NASA low-outgassing test criteria.

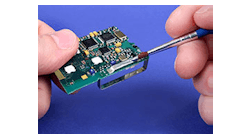

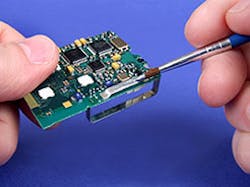

The applications listed in the table below highlight use of Master Bond EP21TDCS-LO in ensuring high-strength, conductive bonds in assemblies designed to survive the harsh conditions of space.